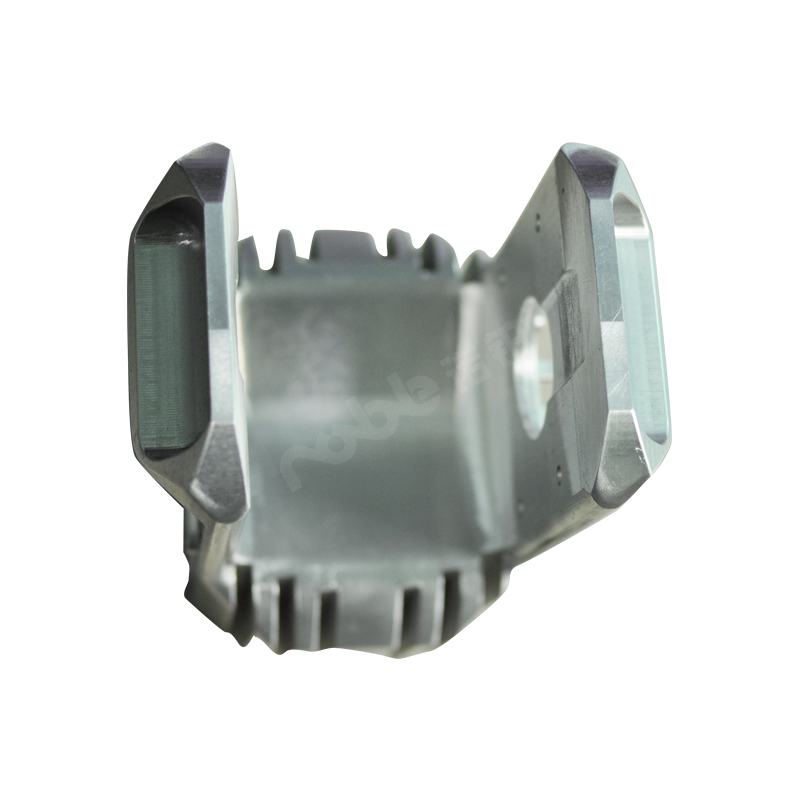

Sheet Metal Parts Manufacturing

If you would like to know what equipment we have, please click here.

Quick Details

| Name | Sheet Metal Parts Manufacturing |

| Materials | Steel Alloy, Aluminum, Brass, Copper, Bronze, Titanium Alloy, Tungsten, etc. |

| Size | Customer’s 3D/2D drawing |

| Color | As your requirement |

| Process | CNC milling, turning, etc. |

| Shipment | Express (DHL, FedEx, TNT, UPS, EMS…), Air freight (EK, TG, TK, MH, ZA, AA, CA, SA), Sea (MSC, COSCO…). |

| Brand name | Noble |

| Palace of origin | Shenzhen, China (mainland) |

What can we do

| Noble CNC Service | Include |

| Main service | 1, Structure design optimization; 2,CNC Machining: to make medium & low volume metal parts 3,Rapid Prototyping: CNC, 3D printing(SLA, SLS); Also we can provide the following service to meet your demand; Rapid Tooling, die-casting, Extrusion molding , Silicone mold vacuum casting, etc. |

| Drawings | 3D: step/stp, igs, prt , sld,etc. 2D:.dwg . pdf. cdr . ai, other pictures format. |

| 3D Software | Pro-e (Creo) UG Solid works Catia Rhinoceros 3dmax |

| 2D Software | AutoCAD Photoshop CorelDraw Adobe Illustrator |

| Plastic Material | ABS, Acrylic/PMMA, PP(Polypropylene),PC(Polycarbonate),PU(Polyurethane),POM(Delran,Acetyl),PVC, PE(Polyethylene), PA(Nylon, Polyamide) PEEK(Polyetheretherketone), Chemical Wood, etc; |

| Metal Material | aluminum, aluminum - magnesium alloy, aluminum - zinc alloy, copper, brass, bronze, stainless steel,SUS303, SUS304, 45 steel, iron, Galvanized steel sheet, sheet metal, SPCC, etc; |

| Manufacture process | 1. CNC Machining Center: Milling, drilling, turning, threading, tapping, boring, facing, spotting, counter boring. 2. CNC Milling: High precision milling, numerical control carving and milling, CNC engraving and milling. 3. CNC Bending: Bending-High precision seamless bending, sheet metal bending. 4. CNC Punching: Punching/stamping-High precision Sheet Metal Fabrication. 5. Welding: GMAW Welding, MIG Welding, Laser welding. 6. Laser cutting: High precision cutting. 7. Molding/Tooling: Rapid Tooling, die-casting, Extrusion molding, Silicone mold vacuum casting, etc. 8. 3D printing: SLA, SLS, FDM. |

| Our advantage | 1. Quick response: we will respond once we get your inquiry, then provide cost within 1 hour. 2. Low price: We can offer you the lowest price of the same quality. 3. Complex parts: Good at machining parts with complicated curved surfaces. 4. Perfect quality: Strictly control the machining and finish treatment quality, what you will get is what you designed. 5. Accurate delivery: Finish the parts in time to provide the strongest support for your R&D projects. 6. Rich experience: More than 10 years of professional machining and rapidv prototyping experience, provide you with the most professional and effective advice. 7. Professional team: Efficient and honest technical and service team, let you enjoy 24H professional services. 8. Fully equipped: Perfect supply chain, complete processes, one-stop solution to all requirements. |

FAQ

- Q

How can I know my order is going without visiting your company?

AWe will make the schedule for each order and send you photos of the machining progress.

- Q

How long is your delivery time?

ANormally it is according to quantity and difficulty of the projects, we will show it in our quotation.

Notice

We support standard part and also welcome customized. Please inform the exact specification of inquiry such as Material, Grade, size etc., if it is special and non-standard products, please supply the drawing or Photos or Samples to us.