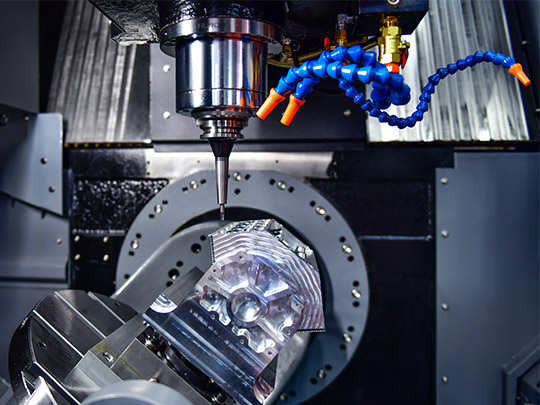

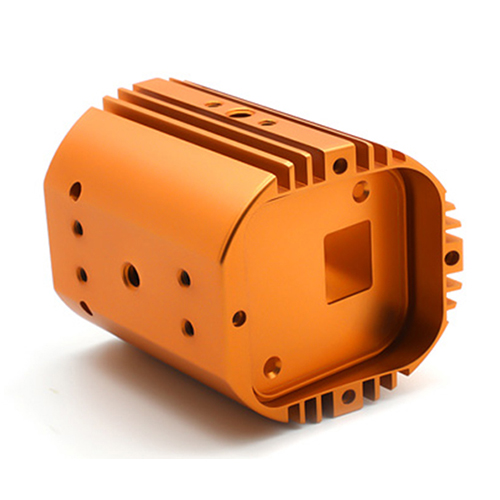

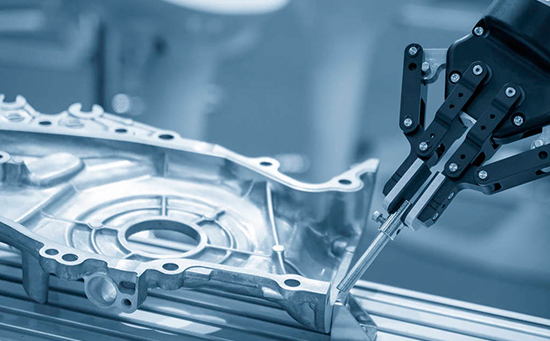

Our CNC Milling Services

With state-of-the-art 3-, 4-, and 5-axis milling equipment, we provide reliable on-demand CNC milling services for rapid prototyping and production parts. Get high-precision, lifelike milled parts custom-made from a variety of metals and plastics at competitive prices.Advanced Equipment & Cost-Effective Price.

- ISO 9001 & ISO13485 Certified Factory

- 10+ Years of CNC Milled Parts

- Tight Tolerance of 0.001 mm

- 3, 4, 5 Axis Milling Machines

- 24/7 Engineering Support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

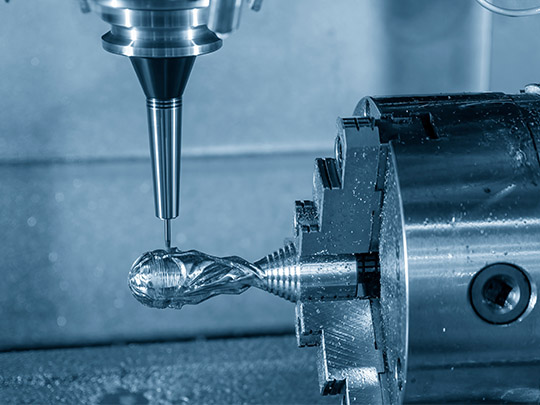

Robust CNC Milling Services

Generally speaking, the type of CNC milling machine is defined by its number of axes. The higher the number of axes, the greater the ability to create complex parts and create cutting angles. Efficiently bring your products to market faster with a reliable CNC milling company. From rapid prototyping to custom production, take advantage of premium 3-axis, 4-axis, and full 5-axis CNC milling for high precision and high-quality CNC milled products. NOBLE provides high-quality CNC milling services to help you transform your designs into complex geometries. Take control of your CNC milling projects and obtain custom parts to your exact requirements by working with our in-house machining team.

A 3-axis CNC mill has a tool that can move along the X, Y, and Z axes.A profitable and efficient solution to your CNC milling needs! We ensure the machining of parts with complex geometrical shapes, including undercut features, threaded holes, sharp edges, and planar profiles. Complete multiple operations through effective integration with an automatic tool changer. We can also design 3-axis milling centers to meet the unique requirements of each client.

- Parts as fast as 2 days

- Fast Turnaround in 7 days

- State-of-the-art Equipment

- Free dimensional inspection reports

Get more complex CNC milled parts with our 4-axis CNC milling. We consistently produce precise and accurate results, with greater control and more flexibility, even with complex shapes. Ensure cost-effective machining of angled features that are rather impossible with 3-axis machines. With more power, greater control, and higher precision, 4-axis milling is your ideal solution.

- 10+ Years of Milling

- 100% Part Inspection

- 1-to-1 Quote Analysis

- Competitive Price 30% Cost Save

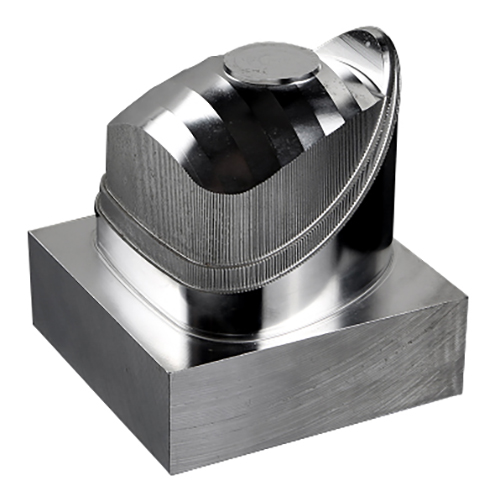

Machine complex custom CNC milled parts with a single setup. Our 5-axis CNC milling machines save time, improve efficiency, and reduce cost, ensuring that you meet market demands faster and cost-effectively. We can reach higher cutting speeds without excessive pressure on the cutter. Get rapid prototypes and low-volume production parts with better surface finishes.

- Quote Within 24 hours

- No minimum order quantity

- Tolerances Down to +/- 0.001 inch

- Over 100 materials and 30 finishes available

Our CNC grinding machining service will be your best option if you need a very flat surface item or a round part with tolerances of OD and ID ±0.005mm for your production demands.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Grinding Services.

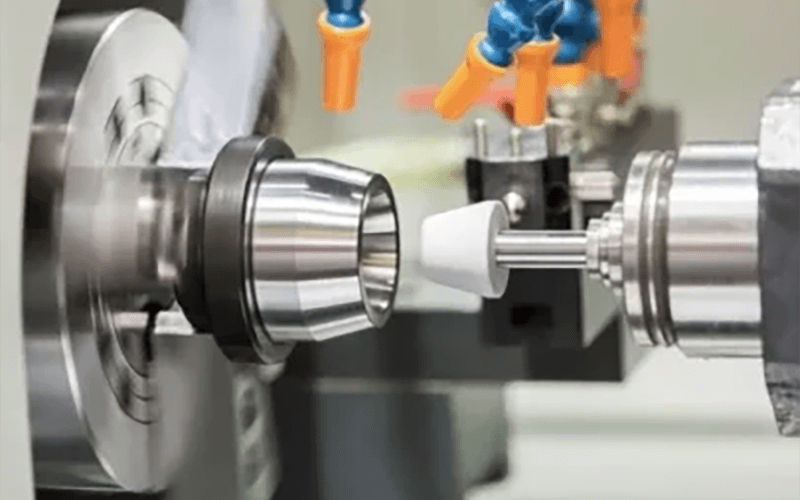

Swiss machining is a productive method for creating thin or complex parts. We can always cut the material that is near the workpiece holder by moving the workpiece as well as the active tooling. To prevent distortion in contrast to a conventional CNC lathe.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Swiss Machining Services.

We provide CNC routing services for prototypes and parts machining of soft materials like EPS foam, EVA, and wood in addition to regular milling services for parts made of engineering plastics or metals.

- 10+ Years of CNC Routing

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

Our Robust CNC Milling Capabilities

Our Excellent CNC Milling Services

Our advanced facilities conclude imported 3-axis, 4-axis, and 5-axis CNC mills that are equipped with different tool sets to maximize production efficiency and speed. Send us your inquiry or 3D files online to get an online quote for free now.

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for CNC Milling Services

We offer CNC milling services for any type of custom CNC parts, whether plastics or metals, simple or complex. Our precision 3-, 4-, and 5-axis CNC machines, combined with other advanced capabilities and our experienced team, can provide high-quality CNC machined parts and fast delivery. We guarantee your CNC milling projects will be handled smoothly by our in-house CNC machining department and supplier network. As a result, you can focus on bringing your product to market. If you need a reliable CNC milling company, NOBLE will never let you down!

Milled Parts with Tight Tolerances

We implement strict quality management to ensure consistent high quality on your CNC milled parts. Provide full-dimensional and material inspection reports on your request. With strong CNC milling capabilities and technological implementations, all your custom CNC milled parts will meet tolerances as tight as ±0.01mm.

Material Options

Over 50 metal and plastic materials and a wide type of surface finish for your choice.

Fast Lead Time

Not only do we have a digital CNC machining services platform that provides a faster ordering process, but we also own domestic workshops and state-of-the-art machinery to accelerate the production of your prototypes or parts.

24/7 Engineering Support

No matter where you are, you can get our 24/7 engineering support all year around. Our experienced engineer can provide you with the most appropriate solution for your part design, material selection, surface finishing options, and even lead time.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Advantages of CNC Milling Processes

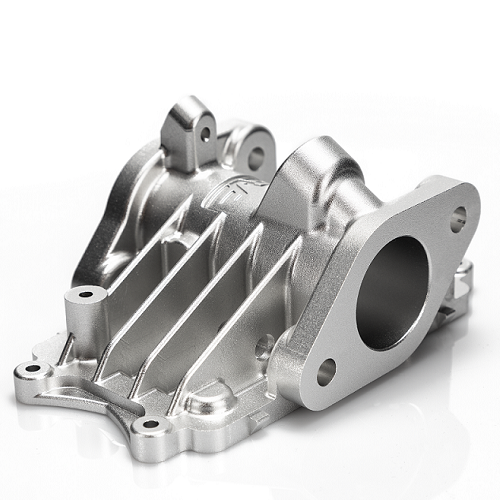

CNC milling is the process of cutting solid plastic or metal materials into final precision parts using different axis milling processes. Multi-axis milling machines enable versatile, accurate, and repeatable CNC milling processes to produce different features and complex geometries. Milling can also be used as a perfect way to manufacture die-casting and injection molds.

CNC Milling Tolerances

NOBLE offers a range of CNC machining tolerances to suit your unique design requirements, including GD&T callouts. Based on your part’s geometry and chosen material, we can accommodate standard thread sizes, machine custom treads, and reach tolerances of up to ±0.001”. Our standard tolerances for CNC milled metals are ISO 2768-m and ISO 2768-c for plastics.

| Type | Tolerance |

| Linear dimension | ±0.025mm-± 0.001inch |

| Hole diameters | ±0.025mm-± 0.001inch |

| Shaft diameters | ±0.025mm-± 0.001inch |

| Part size limit | 950 * 550 * 480 mm-37.0 * 21.5 * 18.5 inch |

Materials for CNC Milling Parts

Depending on your applications, our CNC milling process is compatible with an extensive range of materials. We stock over 30 production-grade metal alloys for producing various CNC milled parts for different industries. In addition to metals, NOBLE’s high-precision CNC milling service is also compatible with many plastic materials. Check out some of the widely used materials for CNC milling parts.

Aluminum

Aluminum is a highly ductile metal, making it easy to machining. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Price: $

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Plastics

Plastics are also a very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

Machinable Material Types: POM, HDPE, PET, Nylon, PTFE, PVC,

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

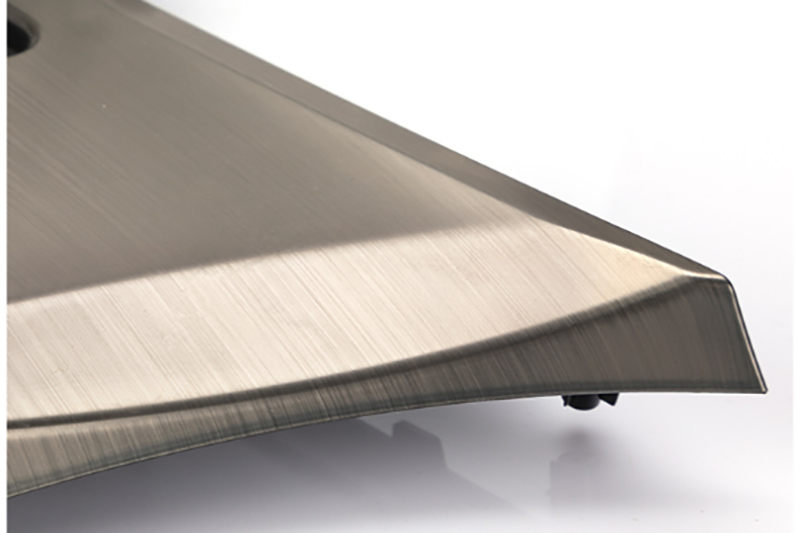

Surface Finishes for CNC Milling

Gain access to quality surface finishing for custom CNC milling parts to remove aesthetic flaws and improve the appearance of your products. We also provide rigid protection and additional resistance and strength to your parts through superior surface finishes.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Bead Blasting

Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Matte

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

Please check out our over ten years of CNC milling precision parts, which showcases precision-milled prototypes and parts from our valued customers.

See What Our Customers Say About Us

NOBLE has been engaged in CNC machining services for more than ten years and has served many overseas customers. The words of customers are more substantively representative than the company’s statement–see the objective evaluation of our satisfied customers.

Mark Alford

Vice President

From the instant and accurate quotation to the production process to the timely delivery of parts, NOBLE responded to our demands with complete professionalism.They handled every aspect of this CNC machining project quickly and cost-effectively.We will surely work with them again in the future.

Luc Szorc

Mechanical Engineer

Hi, Kevin. l’d like to thank you and everybody at NOBLE for contributing to the great service we received. Youconstantly handle our difficult CNC machining projects, and offer instant quotation and free DFM analysis for thepart desian. Best of al, you show superior guality in short lead times. Our department supervisor confirmed that youwill continue making these parts now, The auality is outstanding!

Hari Mackenzie

Engineer

We asked NOBLE to fabricate parts for a critical supplier demo, and you came through with a short lead time.Your work is always high quality, and we are grateful for your precision in machining components. The help in checking our designs and material selection has also saved our company from making expensive errors.We look forward to doing future projects with you guys.

Raymond

Vice President

Parts arrived for us today, Such beautiful miled parts mate! Our team assemble the parts earlier which goessmoothly. Parts are as precise as we expected. Please pass my thanks to your production team, They are doing agreat job! l am so glad that we found you guys online and eventually ordered from you guys. We are going to senoyou more CNC milling projects for quote soon.

CNC Milling Applications

Because CNC machining can achieve high precision without changing the material structure with good manufacturing speed, it is becoming growing common as the range of machines, control systems, and tools for CNC machining continues to expand.NOBLE is dedicated to providing precision machining services for various industries and our precision CNC-crafted parts can be found in all areas of the industry, including.

Oil & Gas

Experts at NOBLE master the comprehensive knowledge of CNC machining for the oil field and gas industry paired with the assurance of high precision offered by top-notch CNC machines.

Tool & Die

NOBLE may be your best choice whether you need precision lathe work or multi-axis CNC milling for high-quality tools and dies toaccurately function in the machinery.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

CNC Milling FAQs

CNC milling is just one of the CNC machining processes available. Milling is a particular form of precision CNC machining. Milling uses a cutter that removes material by moving into the workpiece at an angle. The movement of the cutter is controlled by computer instructions, allowing for extreme precision and repeatability.

Besides CNC turning, CNC milling is one of the most popular custom CNC machining processes. CNC milling services are used for the majority of machined parts because it can handle a wide variety of irregular geometries. It is also an efficient means of mass production once the setup is complete.

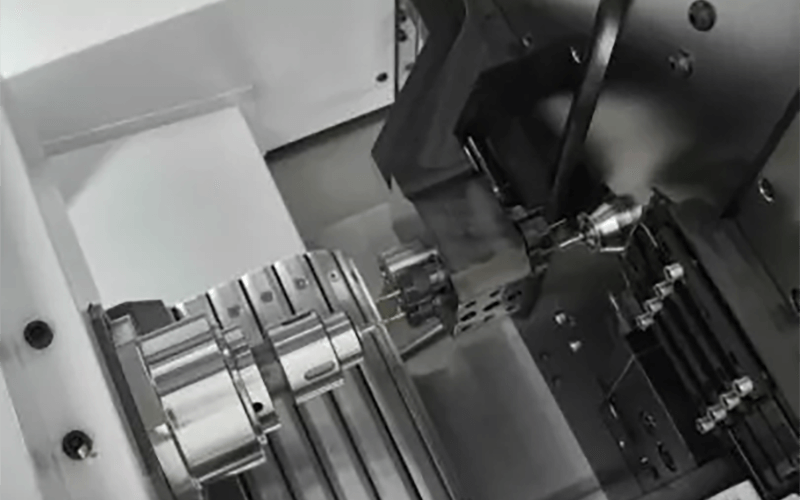

NOBLE works with vertical, horizontal, and multi-axis milling machines. The vertical milling machine is highly accurate equipment that carries out 3-axis milling, suitable for vertical surfaces and angular shapes.

Our horizontal milling machines perform 4-axis milling and are suitable for heavy milling operations. Our multi-axis milling machines can move along different axes and cut at various angles. They include 2-, 3-, 4-, and 5-axis CNC milling machines.

Yes, you can combine both manufacturing processes to reinforce your custom parts. Printed parts can be milled to achieve dimensions with tight tolerances or to meet surface quality requirements. Intelligently combining these two methods can ensure faster manufacturing, less waste, and lower costs. It even achieves higher accuracy and precision, repeatability, and sustainable production.

CNC milling starts with designing a digital part with CAD software. Then the file will be converted into CNC readable program code, which can be recognized by a CNC mill and dictates to the mill how to rapidly fabricate parts from raw material blocks.

Different from CNC lathes or turning centers where a stationary cutting tool removes material by making contact with the spinning workpiece, CNC mills cut away block or bar stock by a rapidly rotating cutting tool moving against the workpiece. The tool path is controlled by computer instructions, enabling improved reliability and repeatability regardless of potential human error.

Different milling types can achieve different functions and can be suitable for different applications. Usually, CNC milling services can be divided into the main 8 types of operations:

- Gear Milling

- Thread Milling

- Plain Milling

- Form Milling

- Face Milling

- Angular Milling

- Profile Milling

- Straddle Milling

We quote German and Japanese advanced equipment including imported three-axis, four-axis, and five-axis CNC milling machines equipped with different tool sets to maximize production efficiency and speed.

CNC milling is used to produce many typical geometry parts with tight tolerances and high accuracy. In the precision CNC milling design process, we recommend typical CNC milling parts including complex planes, curved surfaces, shell parts, connecting rods, propellers, and component housings. But consumers should also notice that some factors like thin walls, deep cavities, and inner wall cutouts may be not suitable for the CNC milling process.

We provide professional design considerations as follows:

- Avoid Sharp Internal Corners.

- Avoid Narrow, Deep Slots.

- Avoid flimsy shapes.

- Corner radio of 10% or more of wall height is ideal.

- Avoid flimsy shapes.

- Practical shape as straight edges.

- Weak shapes are difficult to be milled, such as long thin shapes and thin walls.

- Visible cutting surface pattern for cutter rotation and movement.

The major difference between CNC milling and CNC lathe is in their machining process. CNC milling involves rotating the cutting tools against a stationary bar stock or workpiece. In contrast, a CNC lather works by rotating the bar stock or workpiece against a stationary tool. CNC milling is more suitable for machining irregular and flat surfaces, while CNC lathes work best for cylindrical or conical parts.