Zinc Die Casting Services

Our Custom Zinc Die Casting Service

Custom zinc dies casting service with excellent quality and competitive price. Receive gravity zinc die-casting casting quotes and design feedback within hours to determine the best choice for your project.

- Advanced Equipment & Cost-Effective Price

- ISO 9001 & ISO13485 Certified Factory

- Instant 10+ Years of Zinc Die Casting

- Lead Time As Fast As 3 Days

- Tolerance Down To 0.001mm

- Free 7/24 Technical Support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Powerful CNC Machining Processes

Providing custom CNC machining solutions at competitive prices, we choose from over 100 materials and 60+ surface finishes to ensure you receive high-precision, structurally complex, and performance-stable parts. Try our precision CNC machining services and become our next satisfied customer.

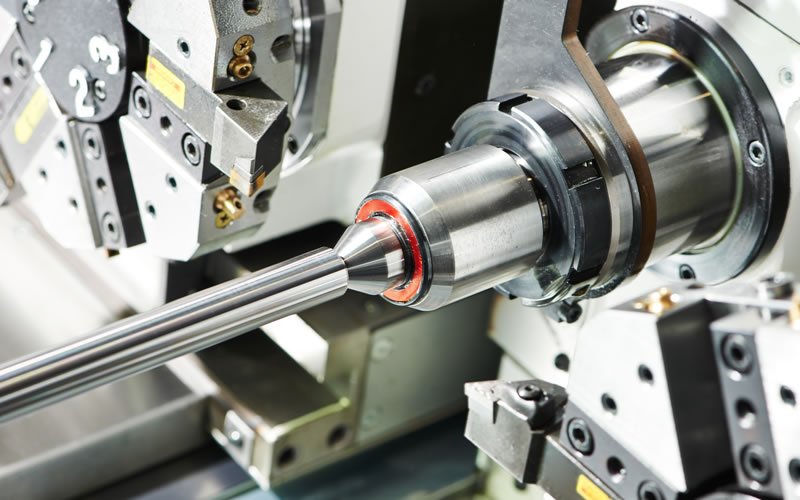

CNC turning is the process of cutting metal or plastic parts with cylindrical features from the outside of a bar with a rotating tool. The turning process can effectively manufacture circular parts and can be applied to create parts with complex internal and external geometries and various threads.

- Tolerances Down to ± 0.0003 In.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Milling Services

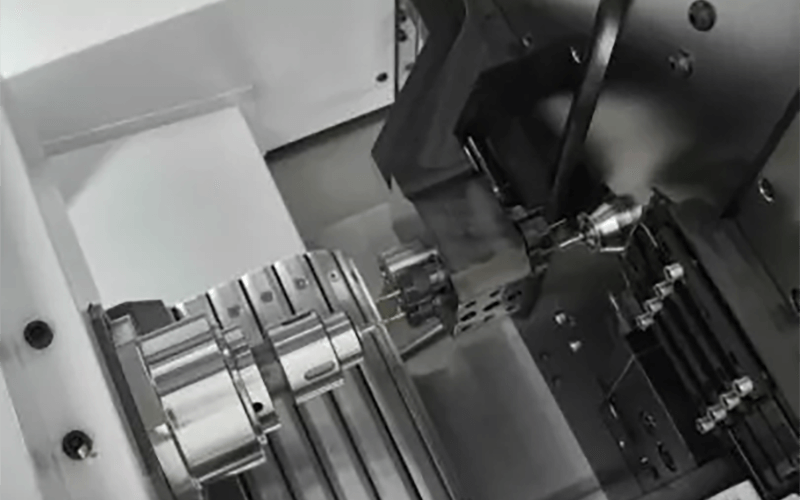

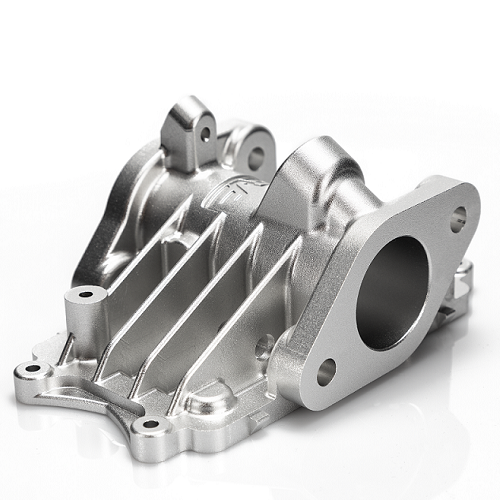

CNC milling is a subtractive process that uses 3-, 4-, and 5-axis milling machines and a variety of cutting tools to remove material from solid blocks of plastic and metal into final parts with varying geometries. With our 3-axis and 5-axis CNC milling services, you will be able to get milled parts with a tolerance of 0. 01mm.

- Tolerances Down to ± 0.0002 In.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- Quick Turn Turning Services

EDM and wire-cutting are CNC machining processes that use copper, graphite, or molybdenum wire to get the desired design for undercuts, sharp corners, and the removal of unnecessary material from workpieces. EDM is also frequently used to produce mold and rapid tooling.

- State-of-the-art Equipment

- 10+ Years of EDM & Wire-Cut

- Fast Turnaround in 7 days

- 1-to-1 Quote Analysis

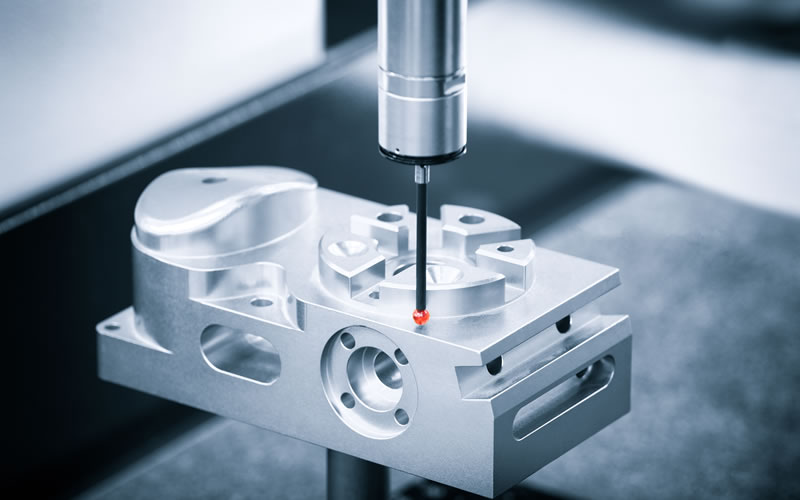

Our CNC grinding machining service will be your best option if you need a very flat surface item or a round part with tolerances of OD and ID ±0.005mm for your production demands.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Grinding Services.

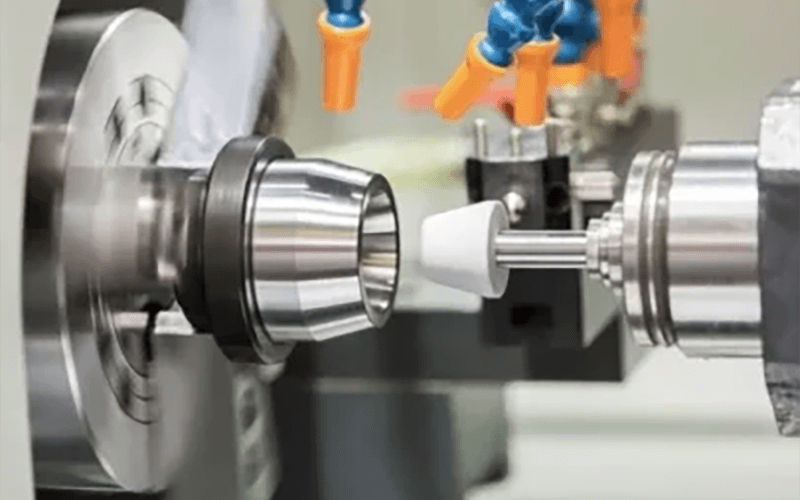

Swiss machining is a productive method for creating thin or complex parts. We can always cut the material that is near the workpiece holder by moving the workpiece as well as the active tooling. To prevent distortion in contrast to a conventional CNC lathe.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Swiss Machining Services.

We provide CNC routing services for prototypes and parts machining of soft materials like EPS foam, EVA, and wood in addition to regular milling services for parts made of engineering plastics or metals.

- 10+ Years of CNC Routing

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

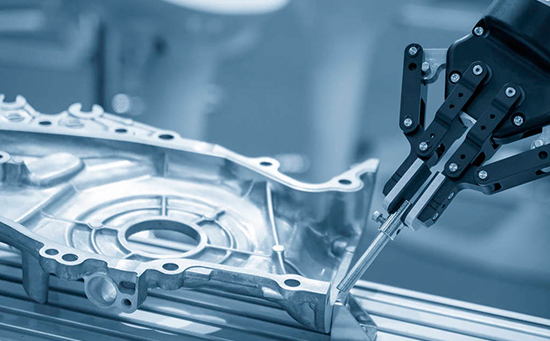

Our Robust Zinc Die Casting Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Custom Zinc Die Casting Services

NOBLE Zinc Alloy Manufacturer puts customers first, utilizing cutting-edge zinc alloy die-casting technology and experienced engineers to provide precise, efficient, affordable, and flawless custom zinc die-casting services to help your business become more successful.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Hot Chamber Zinc Die Casting Service Advantages

Zinc die casting is a hot Chamber die casting manufacturing process. Hot chamber zinc die casting uses high pressure to pump molten zinc into a mold to create complicated parts and components with extreme precision and accuracy. From low-volume production to mass production, hot chamber zinc die casting is a good manufacturing process.

Zinc Die Casting Tolerances and Standards

NOBLE is a custom zinc die-casting manufacturer with 12 years of experience, offering unparalleled zinc alloy die-casting in a variety of sizes and surface treatments at competitive prices. Send us your zinc alloy die-cast design and start your first order with a 30% discount.

| Standard | Capabilities |

| Casting Size (mm) | 10-250 |

| Maximum Casting Weight (kg) | 10 |

| Minimum Wall Thickness (mm) | 0.5 |

| Tolerance (mm) | 0.02 |

| Surface Finish | Ra1.6 |

| Tolerance | CT4-CT7 |

| MOQ | NO MOQ |

| Additional Services | CNC machining, Powder coating, Anodizing, Assembly, Packaging, etc. |

Materials for Custom Zinc Die Casting

The qualities of cast zinc alloys vary depending on the alloy composition and manufacturing factors. Some general features of common cast zinc alloys are as follows:

| Alloy Grade | Zamak 2 | Zamak 3 | Zamak 5 | Zamak 7 | ZA-8 |

| Density (g/cm³) | 6.7 | 6.6 | 6.7 | 6.8 | 6.9 |

| Melting Point (℃) | 383-386 | 381-387 | 379-386 | 380-386 | 381-387 |

| Thermal Conductivity (W/m`K) | 109 | 116 | 113 | 113 | 116 |

| Coefficient of Thermal Expansion (10^-6/K) | 26.5 | 27.5 | 26.9 | 26.5 | 26.5 |

| Electrical Conductivity (% IACS) | 27 | 27 | 27 | 27 | 26 |

| Main Chemical Composition | 3.5-4.3% Al 0.02-0.05% Mg 0.035-0.06% Cu | 3.5-4.3% Al 0.03% Mg 0.03% Cu | 3.5-4.3% Al 0.035% Mg 0.035% Cu | 3.5-4.3% Al 0.03-0.06% Mg 0.03-0.06% Cu | 3.5-4.3% Al 0.05-0.5% Mg 0.005-0.03% Cu 0.005-0.03% Ni 0.005-0.03% Fe |

| Tensile Strength (MPa) | 295 | 255 | 310 | 345 | 380 |

| Yield Strength (MPa) | 240 | 215 | 230 | 275 | 320 |

| Elongation (%) | 2 | 3 | 6 | 3 | 1 |

| Hardness (HB) | 82 | 70 | 90 | 95 | 100 |

| Main Differences | Contains less Mg and Cu, suitable for larger parts | Contains less Mg and Cu, suitable for larger parts | Contains less Mg and Cu, suitable for larger parts | Contains more Mg and Cu, suitable for complex-shaped parts | Contains Mg, Cu, Ni, and Fe, with higher strength and hardness |

| Main Casting Applications | Automotive, furniture, appliances, mechanical parts | Electrical, hand tools, toys | Machinery, architectural, automotive | Automotive, electrical, hardware | Industrial, automotive, electrical |

Aluminum

Aluminum is a highly ductile metal, making it easy to machining. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Price: $

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Plastics

Plastics are also a very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

Machinable Material Types: POM, HDPE, PET, Nylon, PTFE, PVC,

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Surface Finishes for Zinc Die Casting

NOBLE offers customizable surface finishes that elevate your product’s appearance, resistance, and quality beyond expectations. Our finishes cover tool marks and enhance hardness, roughness, and corrosion resistance. Explore our options for flawless results.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

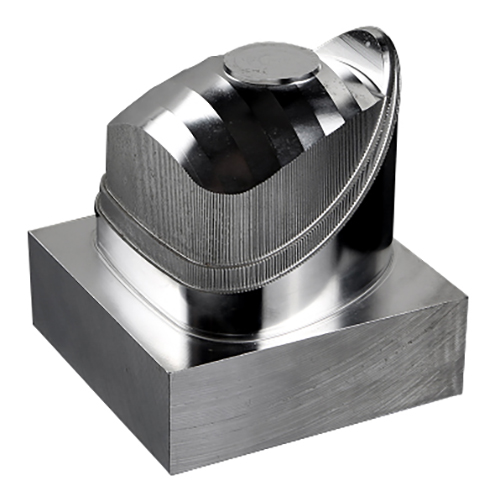

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

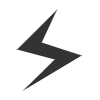

Custom Zinc Die Casting Parts Display

Check out our comprehensive zinc die-cast parts library, which includes custom-made zinc alloy die-cast parts for our valued customers.

Our Zinc Alloy Die-Casting Process Workflow

The hot chamber zinc die casting process is a manufacturing technology that uses molten zinc to make high-precision metal parts. This process’s workflow typically involves the following steps:

Mold Preparation

The first step is to get the mold ready for the die casting procedure. Molds are usually constructed of two sections that are fastened together to produce a cavity.

Molten Zinc Injection

After the mold has been prepared, molten zinc is injected into the cavity. This is accomplished by utilizing a piston to drive molten metal through a nozzle and into the cavity.

Cooling and Solidification

The molten zinc immediately cools and hardens after being injected into the mold cavity, taking on the shape of the mold cavity. The cooling time varies according to the size and complexity of the part being manufactured.

Mold Opening and Part Ejection

The mold is opened and the part is ejected from the cavity when it has cooled and solidified. Ejector pins are often used to force the item out of the mold.

Trimming and Finishing

Following the ejection of the part from the mold, any surplus material or rough edges are removed with various instruments such as saws or grinders. To attain the proper surface finish, the part may also go through further finishing operations such as polishing or coating.

Quality Control

The final step is to inspect the part to confirm that it fulfils the necessary requirements. This may entail checking the dimensions and tolerances of the part with various measurement equipment such as calipers or micrometers.

See What Our Customers Say About Us

The feedback of customers has a greater impact than a company’s advertising. Take a look at what our satisfied customers have to say about how we met their needs.

Jack Thompson

Procurement Manager

Choosing NOBLE for our zinc die casting requirements has been a game-changer for our business. Their expertise and state-of-the-art facilities have allowed us to bring our designs to life with precision and efficiency. The team at NOBLE pays great attention to every detail, resulting in parts that consistently meet our stringent quality standards. Their professionalism, exceptional customer service, and on-time delivery have made them our preferred partner for zinc die casting services. We highly recommend NOBLE for anyone seeking top-quality results.

John Anderson

Mechanical Engineer

I am extremely satisfied with the zinc die casting services provided by NOBLE. The quality of the parts they produced for our project was outstanding. The dimensional accuracy and surface finish were impeccable, meeting our exact specifications. Their attention to detail and commitment to delivering high-quality parts exceeded our expectations. I highly recommend their zinc die casting services for anyone seeking precision and reliability.

Michael Johnson

Product Development Manager

The team at NOBLE zinc die casting has been our go-to partner for zinc die casting services, and they neverdisappoint. Their expertise in the field is evident in the fiawless parts they consistently deliver. From start to finishthelr communication and proiect manaaement have been exceotional, ensurina a smooth and eficient processWe appreciate their commitment to meeting deadlines without compromising on quality. We highly recommendNOBLEzinc die casting for their top-notch zinc die casting services.

David Smith

Operations Director

We have been working with NOBLE for several vears for our zinc die casting needs, and they have consistentlyexceeded our expectations. The parts they produce are of exceptional quality, exhibiting excellent dimensionaaccuracy and surface finish. Their team is responsive, knowledgeable, and always wiling to go the extra mile toensure our satisfaction. We value their commitment to delivering on time and their ability to handle both small andlarge-scale proiects, NOBLE is ourtrusted partner for zinc die castina services.

Zinc Die Casting Applications

Zinc die casting plays an important role in parts manufacturing in automotive, aerospace, electronics, appliances, telecommunications, and medical equipment.

Automotive

Zinc die casting produces intricate shapes, maintains precise tolerances, and delivers impeccably finished parts. It's an ideal choice for automotive components, such as gears, cylinders, gladhands, and small engine parts.

Aerospace

The aerospace industry relies on the essential manufacturing process of zinc die casting due to its ability to produce complex shapes, maintain tight tolerances, and deliver high-quality finished parts. The lightweight and durable characteristics of zinc die casting components contribute to improved fuel efficiency, increased payload capacity, and enhanced overall performance of aerospace vehicles.

Medical Devices

The safety, functionality, and effectiveness of medical devices and equipment are enhanced by the precise and durable characteristics of zinc die casting components. Such components are utilized in common medical parts like forceps, clamps, scissors, and retractors.

Robotics

Zinc die casting is advantageous in robotics because it can create intricate shapes and precise results at a cost-efficient price. It's commonly used to produce parts like robot frames, housings, and joints.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Zinc Die Casting FAQs

Zinc strength, ductility, and stability enable specialists to create a more durable product. This high ductility makes zinc perfect for die casting processes that require pressure and expansion to be maintained without fracturing.

Die-cast zinc is cheaper to produce than stainless steel. Stainless steel is more expensive to produce than zinc. Zinc alloys are more resistant than stainless steel and are used for thin-walled profiles. Stainless steel is far inferior to zinc alloy in terms of thin-walled sections.

Zinc casting alloys are strong, long-lasting, and low-cost engineering materials. No other alloy system combines strength, toughness, rigidity, bearing performance, and cost-effective castability.

The combination of low melting point, excellent fluidity, dimensional accuracy, surface finish, strength, corrosion resistance, and recyclability makes zinc a favorable material for die casting. These properties contribute to the production of high-quality, precise, and cost-effective parts in various industries.

The melting temperature is one of the most visible variances. Zinc melts at a lower temperature than aluminum, magnesium, and brass, at 723°F. As a result, zinc requires less energy to reach a molten state than other die cast metals.

When exposed to moisture and other environmental conditions, zinc corrodes. However, the corrosion that occurs does not cause the part to rust in a brown and orange color or considerably weaken it. As a result, zinc die casting is both economical and robust, and it may be employed in a range of industries.

The required usual minimum wall thickness in zinc die castings is 0.040″ (compared to 0.060″ in aluminium die casting). However, thanks to today’s better die casting and alloy technology, die casting components with wall thicknesses as low as 0.008″ have been produced.