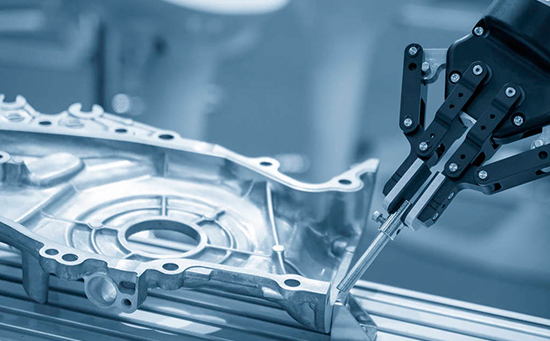

Aluminum Alloy Machining

Our Custom Aluminum Alloy Machining Services

Get instant quotes on custom aluminum machined parts with our Aluminum Alloy Machining Service. NOBLE always ready for the challenges of tight tolerances and complex aluminum alloy machined parts. Try out our precision aluminum alloy machining services and become our next satisfied customer. Make quick-turn prototypes and produce Aluminum Alloy Parts in days.

- Advanced Equipment & Cost-Effective Price

- 10+ years of CNC Machining Parts

- Tolerance as tight as ±0.01 mm

- ISO 9001 & ISO 13485 Certified Factory

- Machining Parts As Fast As 2 Days

- No Minimum Order Quantity

- 24/7 Engineering Support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

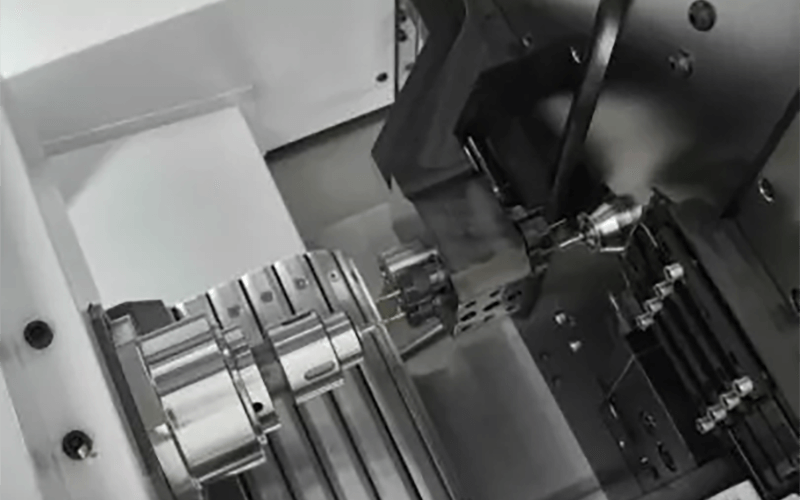

Our Robust Aluminum Machining Processes

Providing custom aluminum machining solutions at competitive prices, We can process all types of aluminum alloy materials on the market and provide more than 60 surface treatment services to ensure that you get high-precision, complex structures aluminum machining parts. Try our precision aluminum machining services and become our next satisfied customer.

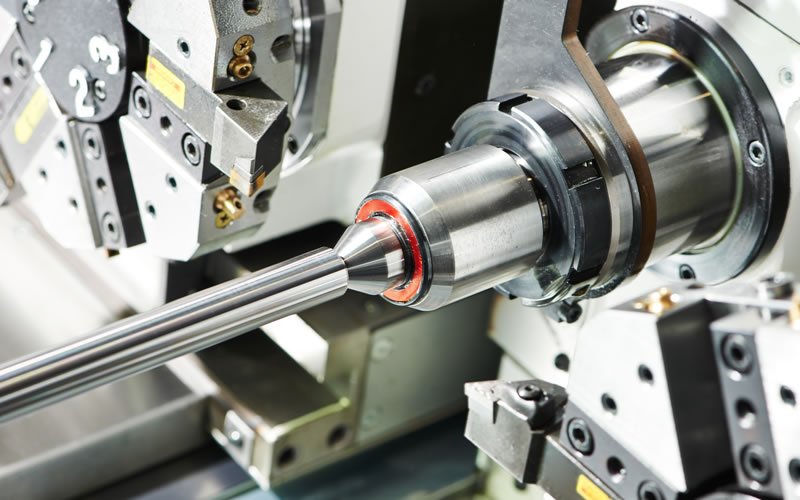

CNC turning is the process of cutting metal or plastic parts with cylindrical features from the outside of a bar with a rotating tool. The turning process can effectively manufacture circular parts and can be applied to create parts with complex internal and external geometries and various threads.

- Tolerances Down to ± 0.0003 In.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Milling Services

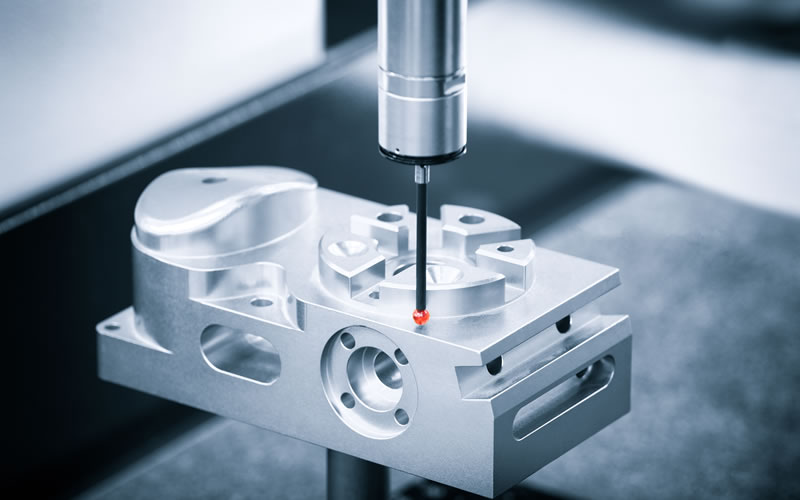

CNC milling is a subtractive process that uses 3-, 4-, and 5-axis milling machines and a variety of cutting tools to remove material from solid blocks of plastic and metal into final parts with varying geometries. With our 3-axis and 5-axis CNC milling services, you will be able to get milled parts with a tolerance of 0. 01mm.

- Tolerances Down to ± 0.0002 In.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- Quick Turn Turning Services

EDM and wire-cutting are CNC machining processes that use copper, graphite, or molybdenum wire to get the desired design for undercuts, sharp corners, and the removal of unnecessary material from workpieces. EDM is also frequently used to produce mold and rapid tooling.

- State-of-the-art Equipment

- 10+ Years of EDM & Wire-Cut

- Fast Turnaround in 7 days

- 1-to-1 Quote Analysis

Our CNC grinding machining service will be your best option if you need a very flat surface item or a round part with tolerances of OD and ID ±0.005mm for your production demands.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Grinding Services.

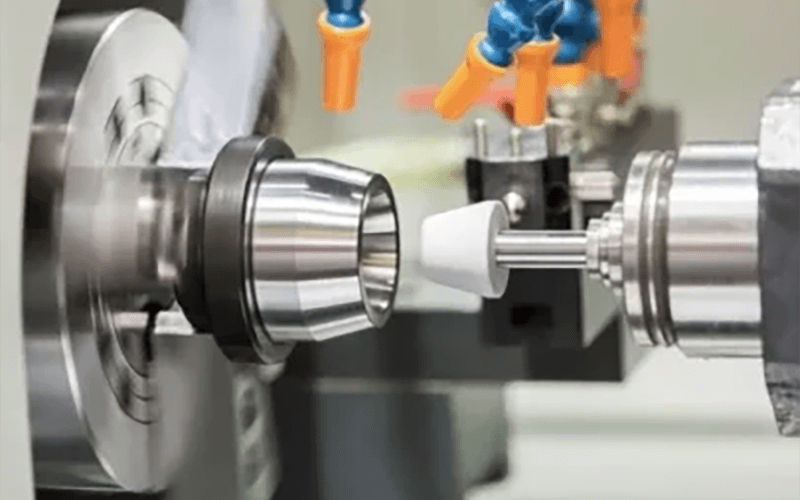

Swiss machining is a productive method for creating thin or complex parts. We can always cut the material that is near the workpiece holder by moving the workpiece as well as the active tooling. To prevent distortion in contrast to a conventional CNC lathe.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Swiss Machining Services.

Customize your precision 5-axis CNC machining services at competitive prices to get high precision, accurate, complex machined parts with extremely complex geometries. Tolerances as low as 0.01mm. Get an instant CNC online quote.

- 10+ Years of 5-axis Aluminum Milling

- 200+Sets of Machine

- 120+Countries Shipped

- 20,000+Customers Served

Our Aluminum Alloy Machining Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Aluminum Alloy Machining Services

For the criticality of applications where aluminum parts are used, you must partner with an experienced aluminum machining services provider like NOBLE. Our in-depth material knowledge, industry understanding, and advanced manufacturing capabilities allow us to ensure the fastest turnaround times in the industry.

Expertise & Experience

With many years of experience in aluminum alloy processing, ensuring a smooth transition from prototyping to production, our experts consistently deliver products that exceed customer expectations, demonstrating our mastery of the complexity of aluminum alloy part manufacturing.

Economical Price

Our price is 20% lower than in Europe and the United States, providing you with the best price on the market.

High Precision Parts

NOBLE specializes in custom manufacturing industrial equipment parts to precise requirements. Our manufacturing capabilities allow us to produce aluminum alloy parts with tolerances as tight as +/- 0.001 inches.

Quality Reliability

Certificated by ISO9001-2015, ISO13485-2016 and Class II medical device production license, we have strict requirements for quality. To meet high quality, we have a sound quality control system and well-equipped measuring devices.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Combined with Other Aluminum Manufacturing Processes

When manufacturing aluminum parts in the hundreds or more, a better solution is needed to get the best results. NOBLE offers several ways to combine 3, 4, or 5-axis CNC machining with other manufacturing processes to create more complex parts capable of increasing mass production. The combination of these processes allows us to maximize the capabilities of aluminum while enjoying the benefits of other manufacturing processes.

The extrusion, casting, and forging processes are all complemented by CNC machining to produce superior-quality aluminum components. Regardless of the test or required properties.

Advantages of Aluminum Alloy Machining

Aluminum is one of the most versatile manufacturing materials in the world, which makes it very popular in a wide range of industries. But why exactly is aluminum suitable for CNC machining? Here are some of the main advantages:

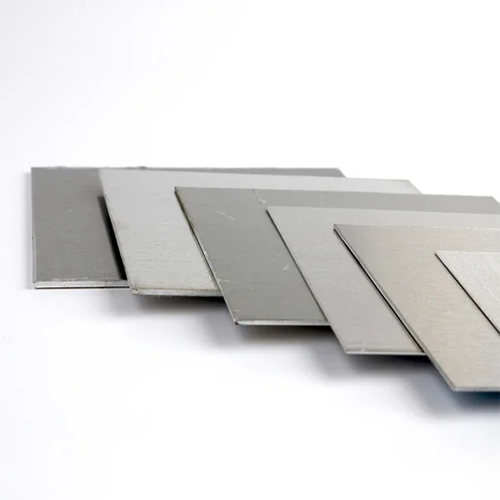

Grade of Aluminum Material Used

Aluminum alloys have a wide range of properties, including flexibility, weldability, high strength-to-weight ratio, corrosion resistance, lightweight, electrical conductivity, and excellent anodizing surface finishing. Due to its low cost and formability, aluminum is widely used in industrial areas. The type of aluminum grade you end up choosing depends on the use of the aluminum part in your manufacturing project.

Aluminum 2024-T3/T4

Aluminum 2024 is used in applications requiring a high strength-to-weight ratio, as well as good fatigue resistance. It has mediocre machinability and cannot be welded. 2024 is not quite suited for anodization due to its low corrosion resistance.

ELASTIC MODULUS (GPA): 72.4

TENSILE STRENGTH (MPA): 485/470

YIELD STRENGTH (MPA): 345/325

APPLICATION: Military, Aerospace, Transportation Industry Etc.

Aluminum 5052-H32

This is the highest-strength alloy of the more non-heat-treatable grades. It is very workable and has good resistance to corrosion from saltwater and the marine atmosphere.

ELASTIC MODULUS (GPA): 70

TENSILE STRENGTH (MPA): 230

YIELD STRENGTH (MPA): 195

APPLICATION: Sheet Metals, Oil Pipes, Traffic Vehicles, Ships, Instruments, Cooking utensils, food processing equipment, Hardware, Electrical Shells, Etc

Aluminum 5083

An excellent corrosion-resistant strain-hardening aluminum alloy is aluminum 5083. Fit for use in maritime environments. Can be welded.

TENSILE STRENGTH (MPA): 275-350

YIELD STRENGTH (MPA): 210

APPLICATION: Ships, Automobile, Aircraft Plates, Pressure Vessels, Refrigerating Devices, Television Towers, Drilling Equipment, Transportation Equipment, Etc

Aluminum 6061-T6

The most adaptable heat-treatable aluminum alloy while retaining the majority of aluminum’s positive attributes. This grade resists corrosion and has a wide variety of mechanical qualities. It offers good workability in the annealed state and can be manufactured using the most regularly used processes.

ELASTIC MODULUS (GPA): 69

TENSILE STRENGTH (MPA): 310

YIELD STRENGTH (MPA): 275

APPLICATION: Automatic Mechanical Parts, Precision Parts, Electronics, Precision Instruments, Etc.

Aluminum 6063-T5/T6

It has good finishing characteristics, a high level of corrosion resistance, and rather strong mechanical properties. most frequently seen in a variety of architectural trim and applications, both outside and indoors.

ELASTIC MODULUS (GPA): 69

TENSILE STRENGTH (MPA): 185

YIELD STRENGTH (MPA): 145

APPLICATION: Construction Profiles, Irrigation Pipes, Bracket, Furniture, Lifts, Fences, Lawn furniture,Etc

Aluminum 7075-T6

One of the strongest aluminum alloys available is aluminum 7075. It works well for heavily stressed sections and has a great strength-to-weight ratio.

ELASTIC MODULUS (GPA): 72

TENSILE STRENGTH (MPA): 570

YIELD STRENGTH (MPA): 505

APPLICATION: Aircraft, Gears, Shafts, Missile Components, Turbines, Mold, Fixtures, Highly stressed parts. etc.

Aluminum 7050

Aluminum 7050 has excellent mechanical qualities including high strength, toughness, good fatigue resistance, and flexibility. Appropriate for use in aerospace applications.

ELASTIC MODULUS (GPA): 72

TENSILE STRENGTH (MPA): 542

YIELD STRENGTH (MPA): 455

APPLICATION: Aerospace, mold machining, mechanical equipment, fixtures, mold manufacturing, electronics, precision instruments, medical industry

Aluminum 6082

The medium-strength alloy aluminum 6082 has outstanding corrosion resistance. Among the alloys in the 6000 class, it has the highest strength. We refer to 6082 as a structural alloy. The most popular alloy for machining in plate form is 6082.

ELASTIC MODULUS (GPA): 68.9

TENSILE STRENGTH (MPA): 205

YIELD STRENGTH (MPA): 240

APPLICATION: Transportation, construction, electronics, chemicals, etc.

Surface Finishes for Aluminum Machining Services

CNC machining leaves visible tool marks during the process of removing portions of the block’s surface to create desired shapes. If you don’t want as-machined parts, select a surface finishing for your custom parts. At NOBLE, we offer several common surface finishes that help improve functionality and aesthetics.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Sand Blasting

Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: ABS, Aluminum, Brass

Color: N/A

Texture: Matte

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

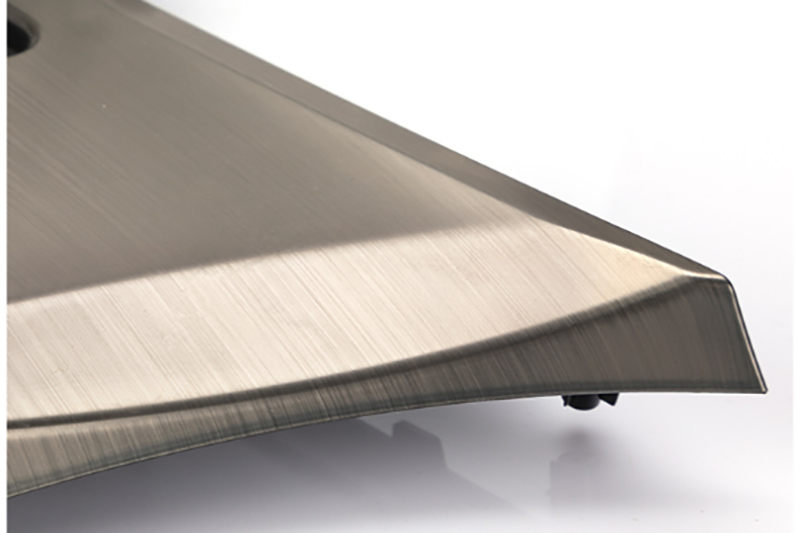

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

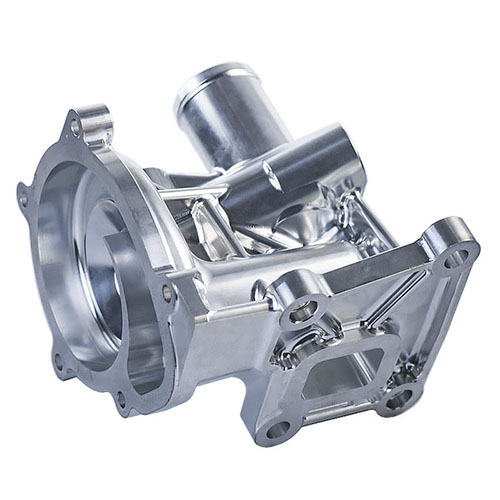

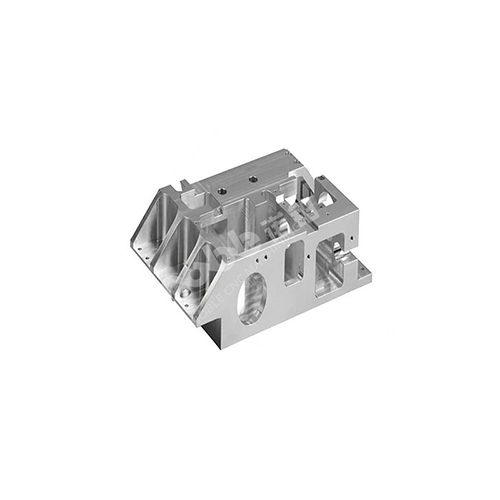

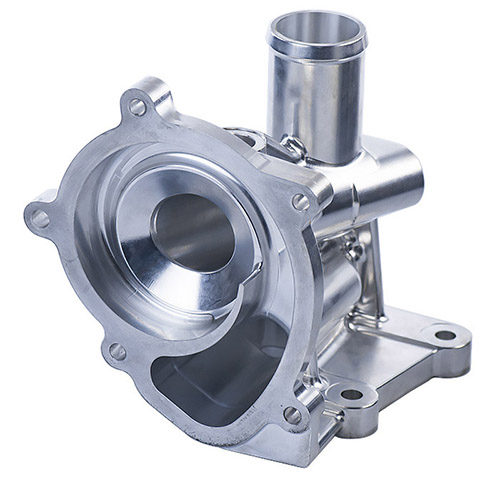

Custom Alloy Machining Parts Display

Get inspired by our custom machining part projects and contact us to Get Instant Quote for rapid prototype or aluminum machined parts start from 1 pcs.

See What Our Customers Say About Us

Customer feedback holds more weight than a company claims – take a look at what our valued customers have to say about our aluminum machining services.

Aaron

Project Engineer

The parts arrived today and we can’t wait to open them up to see, if the parts are as accurate as we expected, the clear silver anodizing on the aluminum parts looks very clean and bright, it was a great collaboration!

Roland Kahn

Mechanical Design Engineer

Whether it’s a new project or a part currently in progress, NOBLE has never disappointed me. They do have a lot of experience and help a lot with the project. Very fast and on time delivery.

Petteri Jauhiainen

Design Manager

It was a great collaboration, thank you to your production team for a job well done! That’s how my projects progress so quickly.

Raymond

Mechanical Engineer

From instant and accurate quotations to the production process, to timely delivery of parts, NOBLE meets our requirements with a professional attitude. They handle every aspect of your aluminum fabrication project quickly and cost-effectively. We will definitely work with them again in the future.

Application of Aluminum CNC Machining

Because CNC machining can achieve high precision without changing the material structure with good manufacturing speed, it is becoming growing common as the range of machines, control systems, and tools for CNC machining continues to expand.NOBLE is dedicated to providing precision machining services for various industries and our precision CNC-crafted parts can be found in all areas of the industry, including.

Oil & Gas

Experts at NOBLE master the comprehensive knowledge of CNC machining for the oil field and gas industry paired with the assurance of high precision offered by top-notch CNC machines.

Tool & Die

NOBLE may be your best choice whether you need precision lathe work or multi-axis CNC milling for high-quality tools and dies toaccurately function in the machinery.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Aluminum CNC Machining FAQs

NOBLE has more than 10 years of experience, we have an experienced engineering team, advanced production and testing equipment, and a mature management system.

Our first step to ensure quality is to choose the right raw material and perfect alloy for production. Next is our well-equipped CNC machine tools. These fully automated computer-operated machines can do magic and make any shape you want. Precision is absolutely accurate and clean, just the way you want it to look.

At every stage of the process, we check and validate all variants to ensure the quality you want. At the end of the process and throughout the quality control process, we do a final check before releasing the final shipment to you. Our excellent quality control team inspects the goods from every angle, ensuring that you receive the highest quality product and are fully satisfied.

The cost will depend largely on the size, material grade of aluminum, and part geometry, as well as the type of fabrication machine your application requires. NOBLE engineers will give you a reasonable quotation according to your needs, effectively reducing your cost.

Designers and engineers are constantly pushing the limits of making parts lighter, thinner, and more versatile. But there is always a limit. If the limit is exceeded, the quality of the part will be threatened.

Wall thickness may depend on the CNC machine itself. According to the capacity and quality of the machine, the walls of high-quality machines can be made thinner. Also, a low-quality machine will not be able to thin the walls as well as a high-performance machine.

Lubrication plays an important role when machining aluminum. It helps cool the heat generated by friction. It also helps the chips not stick to the tool and removes chips from friction points.

Before selecting lubricants, manufacturers need to ensure that they are compatible with aluminum and will not cause any corrosion. It is also antibacterial and environmentally friendly.

Surface finishing is required after die casting or machining. But depending on which type you choose to do for your project, there are often differences in the types of industry part finishes. For example, the finishing of lighting parts is not the same as that of automotive parts. Because they have different goals to achieve the finish.

As a one-stop solution, NOBLE provides you with a wide range of surface treatments. We have cleaning, shot blasting, sandblasting, dusting, chromatin, anodizing, electroless nickel plating, silk screen printing, pad printing, laser engraving, etc.

This process is fully automated. While we require a technician to run it smoothly, the aluminum fabrication service is fully automated. Therefore, we need very advanced machines. Companies that invest more in machinery can provide the highest quality aluminum processing services. If you are interested in any company, first look at what tools they use to process materials, and you will have a clear idea of their capabilities.

NOBLE is equipped with a variety of powerful and durable tools. These tools and our skilled workforce can ensure the best aluminum fabrication services for your company at the highest quality and lower cost. We welcome you to visit our factory to see for yourself how we do it and how it will benefit you.