Our Capabilities

Prototyping, Manufacturing, and Beyond

Leading the industry in rapid prototyping and parts manufacturing, we open the door for product designers and engineers to develop unique products for their market. Our robust production capabilities, comprehensive services, and strong quality control offer fast and cost-effective solutions that will help you improve your brand.

Design plans are reviewed by our team of expert engineers with more than 13 years of combined experience in designing high-performing, cost-effective, and easy-to-manufacture molds. Several factors are considered in each design document, making sure we make the best molds possible.

- Wall Thickness

- Stress

- Aesthetics

- Cost

- Shrinkage

- Functionality

- Dimensional Stability

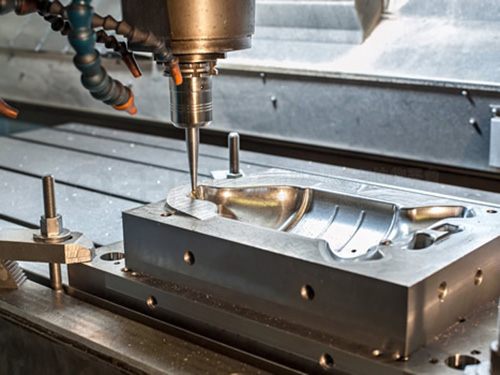

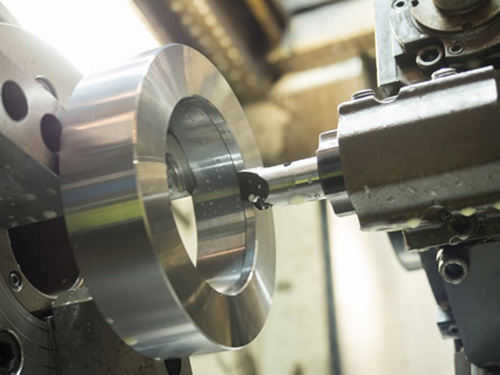

Machining Services We Support

To help designers and engineers bring their concepts into reality, we offer a variety of services that include rapid prototyping and mass production options.

NOBLE, provides high tolerance CNC machining processes including 3, 4, 5 axis CNC milling, CNC turning, and post-processing services for your diverse manufacturing requirements.

| Type | Tolerance |

| Linear dimension | +/- 0. 025 mm +/- 0. 001 inch |

| Hole diameters(not reamed) | +/- 0. 025 mm +/- 0. 001 inch |

| Shaft diameters | +/- 0. 025 mm +/- 0. 001 inch |

| Smallest thread size available | M1x0, 25 |

| Part size limit | 950 * 550 * 480 mm37. 0 * 21. 5 * 18. 5 inch |

NOBLE, provides high tolerance CNC machining processes including 3, 4, 5 axis CNC milling, CNC turning, and post-processing services for your diverse manufacturing requirements.

| Type | Tolerance |

| Linear dimension | +/- 0. 025 mm +/- 0. 001 inch |

| Hole diameters(not reamed) | +/- 0. 025 mm +/- 0. 001 inch |

| Shaft diameters | +/- 0. 025 mm +/- 0. 001 inch |

| Smallest thread size available | M1x0, 25 |

| Part size limit | 950 * 550 * 480 mm37. 0 * 21. 5 * 18. 5 inch |

NOBLE, provides high tolerance CNC machining processes including 3, 4, 5 axis CNC milling, CNC turning, and post-processing services for your diverse manufacturing requirements.

| Type | Tolerance |

| Linear dimension | +/- 0. 025 mm +/- 0. 001 inch |

| Hole diameters(not reamed) | +/- 0. 025 mm +/- 0. 001 inch |

| Shaft diameters | +/- 0. 025 mm +/- 0. 001 inch |

| Smallest thread size available | M1x0, 25 |

| Part size limit | 950 * 550 * 480 mm37. 0 * 21. 5 * 18. 5 inch |

Custom Manufacturing On Demand

Along with our strong manufacturing capabilities, we also provide you the ability to choose the manufacturing volume and other processes that match your production needs.

For batch manufacturing, we have several options to accommodate your requirements, like vacuum casting, CNC machining, and plastic injection molding.

- Lower Cost

- Short Lead Time

- Production-level Quality

- Test Out The Market Before Investment

To complete large-volume manufacturing requirements, take advantage of our plastic injection molding, sheet metal fabrication, and other production processes.

- Parallel Production

- Economies of Scale

- In-house Quality Control

- Reactivity and Fast Production

Not limited to prototyping and parts manufacturing, we also cater to secondary processing demands, including polishing, powder coating, and painting.

- High Precision

- Competitive Price

- Dimensional Integrity

- Component Aesthetics

Quality Control Can be Witnessed Everywhere

NOBLE takes pride in our strict quality control standards applied throughout each section of our production process. Our expert quality auditors pay close attention to detail, inspecting each product for inconsistencies.

Our factory holds an ISO 9001: 2015 certificate – a testament to our dedication to quality.

The facility complies with established manufacturing standards, like DIN-2768-fine and DIN-2768-medium.

Close partnerships with thousands of reliable material suppliers guarantee constant access to quality materials.

Completed prototypes go through various testing machines, like profile projectors, CMM, and 3D scanners.

Our strict commitment to quality control regulations ensures consistent quality is maintained throughout production.

Get comprehensive quality reports from our in-house quality team or third-party labs.

Real Humans, Here to Help

We provide exceptional support even after order completion, giving you the confidence to offer your products to your market. Expert technicians with over a decade of industry experience and vast product expertise assist you with troubleshooting and optimal product use.

Technical Support

Project Management