CNC Machining

One-Stop Custom CNC Machining Services

Get instant online quotes for CNC machined parts in metals or plastics, from rapid prototyping to production. NOBLE provides precision CNC machining services, including milling, turning, grinding, EDM cutting, and surface grinding. Request an online quote today and experience lead times as short as 1 day.

- Advanced Equipment & Cost-Effective Price

- 10+ years of CNC Machining Parts

- ISO 9001 & ISO13485 Certified Factory

- Machining Parts As Fast As 2 Days

- Instant CNC Machining Quotes

- 24/7 Engineering Support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

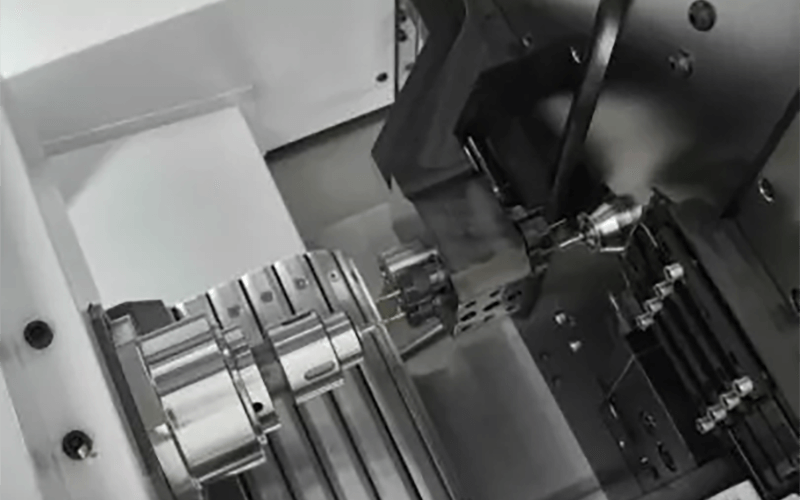

Our Powerful CNC Machining Processes

Providing custom CNC machining solutions at competitive prices, we choose from over 100 materials and 60+ surface finishes to ensure you receive high-precision, structurally complex, and performance-stable parts. Try our precision CNC machining services and become our next satisfied customer.

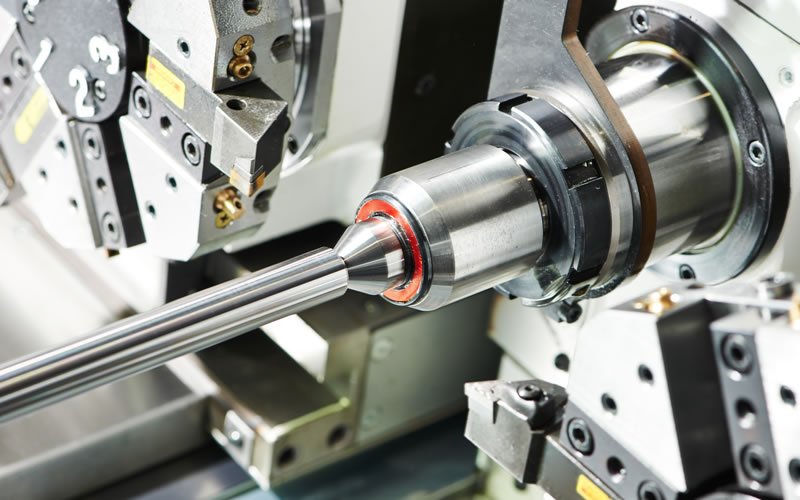

CNC turning is the process of cutting metal or plastic parts with cylindrical features from the outside of a bar with a rotating tool. The turning process can effectively manufacture circular parts and can be applied to create parts with complex internal and external geometries and various threads.

- Tolerances Down to ± 0.0003 In.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Milling Services

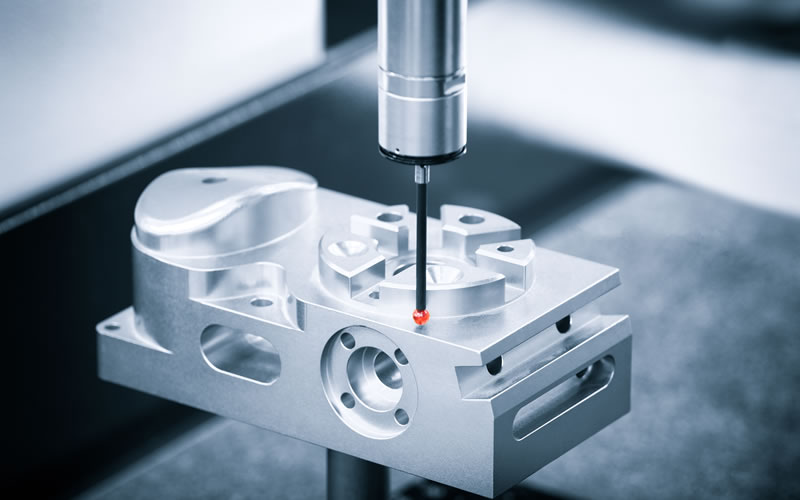

CNC milling is a subtractive process that uses 3-, 4-, and 5-axis milling machines and a variety of cutting tools to remove material from solid blocks of plastic and metal into final parts with varying geometries. With our 3-axis and 5-axis CNC milling services, you will be able to get milled parts with a tolerance of 0. 01mm.

- Tolerances Down to ± 0.0002 In.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- Quick Turn Turning Services

EDM and wire-cutting are CNC machining processes that use copper, graphite, or molybdenum wire to get the desired design for undercuts, sharp corners, and the removal of unnecessary material from workpieces. EDM is also frequently used to produce mold and rapid tooling.

- State-of-the-art Equipment

- 10+ Years of EDM & Wire-Cut

- Fast Turnaround in 7 days

- 1-to-1 Quote Analysis

Our CNC grinding machining service will be your best option if you need a very flat surface item or a round part with tolerances of OD and ID ±0.005mm for your production demands.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Grinding Services.

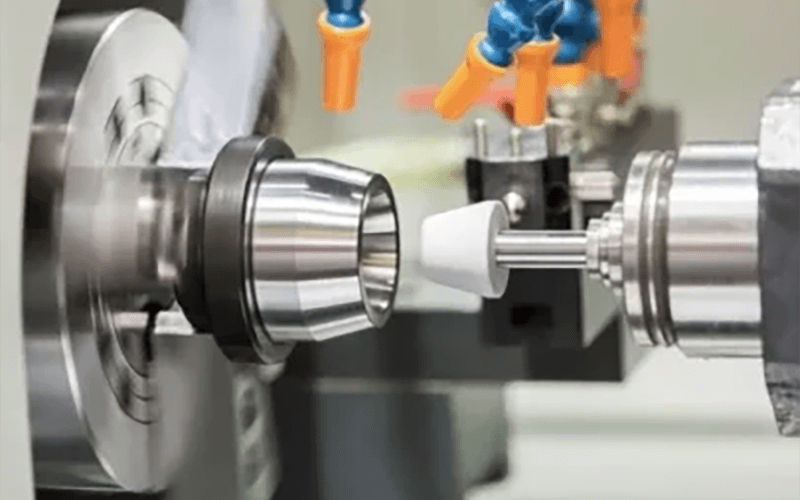

Swiss machining is a productive method for creating thin or complex parts. We can always cut the material that is near the workpiece holder by moving the workpiece as well as the active tooling. To prevent distortion in contrast to a conventional CNC lathe.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Swiss Machining Services.

We provide CNC routing services for prototypes and parts machining of soft materials like EPS foam, EVA, and wood in addition to regular milling services for parts made of engineering plastics or metals.

- 10+ Years of CNC Routing

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

Our Robust CNC Machining Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- Countries Shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique Parts Produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Custom CNC Machining Service

Turn your concept into reality through outstanding on-demand manufacturing services. NOBLE produces simple and complex prototypes and end-use parts with powerful and efficient manufacturing capabilities. All our products meet strict tolerance criteria and quality standards, making us the leading on-demand manufacturing company in China.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

CNC Machining Tolerances and Standards

With precision CNC machining services, NOBLE is your ideal partner to create precision machined prototypes and parts. Our standard CNC machining tolerances for metals is ISO 2768-f and for plastics is ISO 2768-m. We can also achieve special tolerances as long as you indicate your requirements for your drawing.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 2000×1500×600 mm | 200×500 mm |

| Minimum Part Size | 4×4 mm 0. 1×0. 1 in | 2×2 mm 0. 079×0. 079 in |

| Minimum Feature Size | Φ 0. 50 mm Φ 0. 00197 in | Φ 0. 50 mm Φ 0. 00197 in. |

| Standard Tolerances | Metals: ISO 2768-f Plastics: ISO 2768-m | Metals: ISO 2768-f Plastics: ISO 2768-m |

| Hole Diameters | +/- 0. 025 mm +/- 0. 001 in. | +/- 0. 025 mm +/- 0. 001 in |

| Linear Dimension | +/- 0. 025 mm +/- 0. 001 in | +/- 0. 025 mm +/- 0. 001 in. |

| Edge Condition | Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | |

| Shaft Diameters | +/- 0. 025 mm +/- 0. 001 in | +/- 0. 025 mm +/- 0. 001 in. |

| Threads and Tapped Holes | Diameter: Φ 1. 5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 1. 5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

| NOBLE can produce threads of any specification and size required by our customers. | ||

| Text | Minimum width of 0. 5 mm, depth of 0. 1 mm | NOBLE can use laser marking to create standard text for CNC turned parts. |

| Lead Time | 3 business days | 3 business days |

Materials for Custom CNC Machining Parts

Various materials are available for CNC machines, giving you options for rapid prototyping and custom production runs of complex parts. We provide instant quotes on more than 150 metals and plastics for your manufacturing needs, and you can even compare prices on different processed materials.

Aluminum

Aluminum is a highly ductile metal, making it easy to machining. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Price: $

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Plastics

Plastics are also a very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

Machinable Material Types: POM, HDPE, PET, Nylon, PTFE, PVC,

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Surface Finishes for CNC Machining

CNC machining leaves visible tool marks during the process of removing portions of the block’s surface to create desired shapes. If you don’t want as-machined parts, select a surface finishing for your custom parts. At NOBLE, we offer several common surface finishes that help improve functionality and aesthetics.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Sand Blasting

Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: ABS, Aluminum, Brass

Color: N/A

Texture: Matte

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

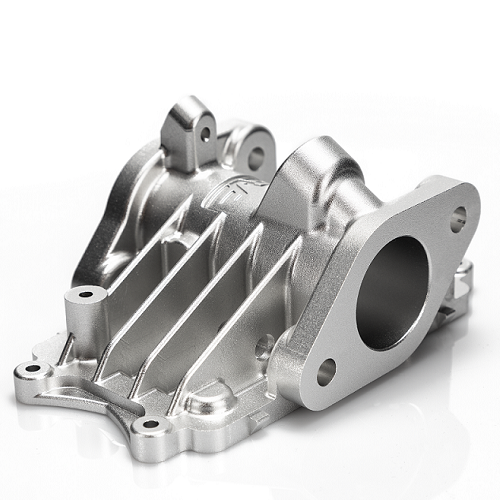

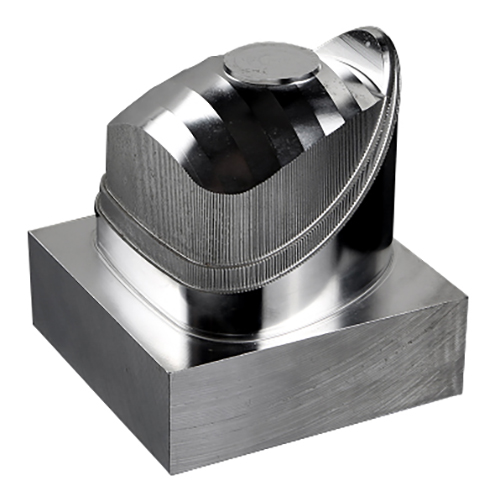

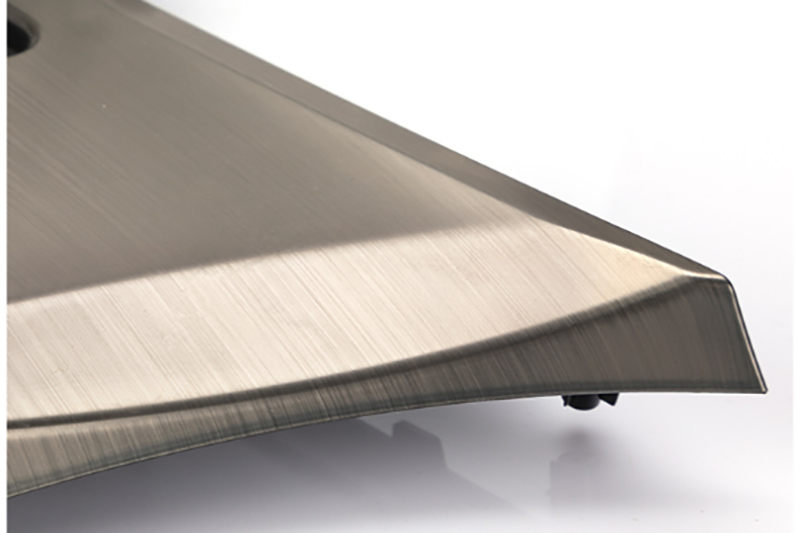

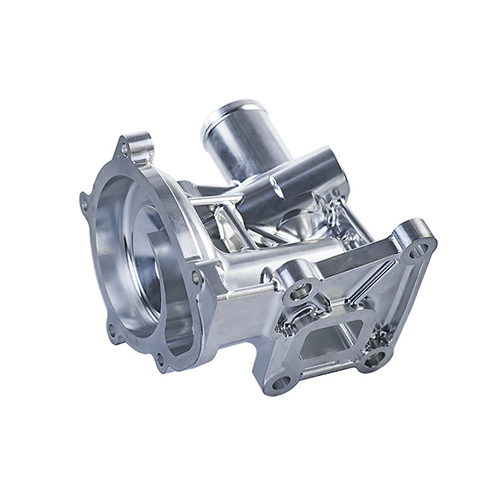

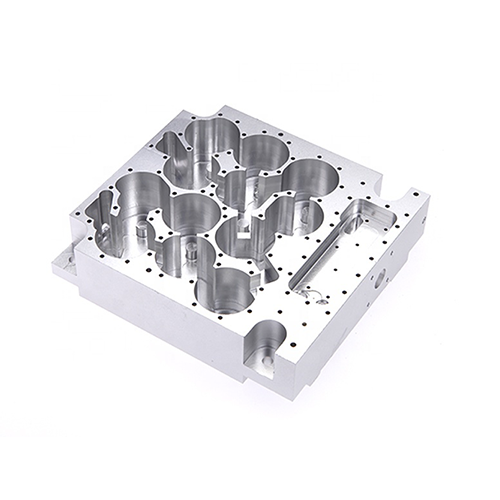

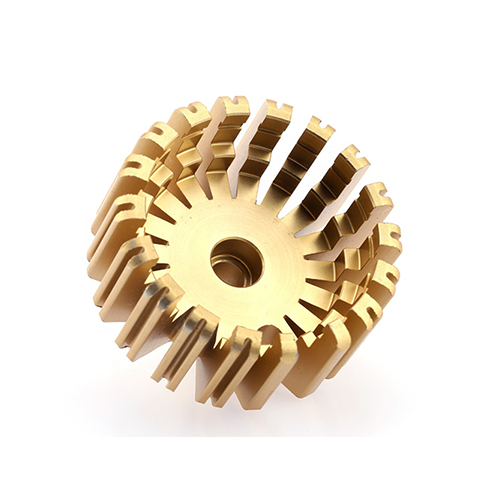

Custom CNC Machining Parts Display

Check out our over a decade of precision custom CNC machined parts, including precision machined prototypes and parts from our valued customers.

See What Our Customers Say About Us

NOBLE has been engaged in CNC Machining services for over ten years and has served many overseas customers. Customers’ words are more substantively representative than the company’s statement–see the objective evaluation of our satisfied customers.

Mark Alford

Vice President

NOBLE responded to our needs with complete professionalism, from the prompt and accurate quote to the production process to the timely delivery of the parts. They handled every aspect of this CNC machining project quickly and cost-effectively. We will definitely work with them again in the future.

Piscary Herskovic

Product Designer

NOBLE has been our quality supplier of CNC machined parts.Fast delivery is very important for our business, and NOBLE always offers short lead time and competitive pricing.Andy responds fast to all our emails and questions.This has improved our working relationship, and we continue to value this partnership.

Hari Mackenzie

Engineer

We asked NOBLE to fabricate parts for a critical supplier demo, and you came through with a short lead time.Your work is always high quality, and we are grateful for your precision in machining components. The help in checking our designs and material selection has also saved our company from making expensive errors.We look forward to doing future projects with you guys.

Stefan Hohmann

Product Manager

My experience with NOBLE has been nothing but exceptional. From the start, the communication has been accurate and fast. Specificities of the design that may meet production difficulties are promptly pointed out with suggested solutions. The price of CNC machined parts is competitive. The QC of the final product is also excellent. There is no doubt that I will go back again.

CNC Machining Applications

Because CNC machining can achieve high precision without changing the material structure with good manufacturing speed, it is becoming growing common as the range of machines, control systems, and tools for CNC machining continues to expand.NOBLE is dedicated to providing precision machining services for various industries and our precision CNC-crafted parts can be found in all areas of the industry, including.

Oil & Gas

Experts at NOBLE master the comprehensive knowledge of CNC machining for the oil field and gas industry paired with the assurance of high precision offered by top-notch CNC machines.

Tool & Die

NOBLE may be your best choice whether you need precision lathe work or multi-axis CNC milling for high-quality tools and dies toaccurately function in the machinery.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

CNC Machining FAQs

CNC machining is a wide-ranging manufacturing category involving multiple computer-managed processes. The objective is to remove enough raw material from a piece to achieve a state of near completion.

The main advantages of CNC machining over traditional methods are greater accuracy, more precise control, and higher efficiency. Precision-turned components milled by CNC machines are of higher quality than those from manually operated machines.

We can serve more than 10000 different prototypes every month, no matter if it is a simple or complex design. We are equipped with a clean assembly workshop of 1000m², have 100 CNC machine tools, and have established more than 30 experienced technical teams and a more complete laboratory.

CNC machining is a fast, accurate and versatile solution for making end-use plastic and metal parts in any quantity, without the need for investing in hard tooling or expensive set-ups. No matter how simple or complex the parts.

There’s a wide range of materials that can be used in CNC machining – you can use such as aluminum, steel, brass, copper, titanium, as well as rigid plastics. Reach out to learn more about the types of materials that could be used.

The main costs associated with CNC machining can be grouped into machining time, start-up costs, material costs, and feature costs. To reduce costs you need to understand the impact of these factors on cost.

1. The best way to reduce machining time is to design features that can be machined quickly, for instance, choosing the correct radii for internal corners, reducing cavity depth, increasing wall thicknesses, limiting thread length, and designing holes with standard sizes.

2. Material costs can be reduced by considering the size of the blank required, and the cost and machinability of the bulk material (softer alloys are faster to machine).

3. Start-up costs can be reduced by reducing the number of part rotations or repositioning required to finish the part, for example, separating geometries into multiple parts that can be assembled later.

4. Feature costs can be reduced by only using tolerances when strictly necessary, removing all text & lettering, and avoiding multiple surface finishes.

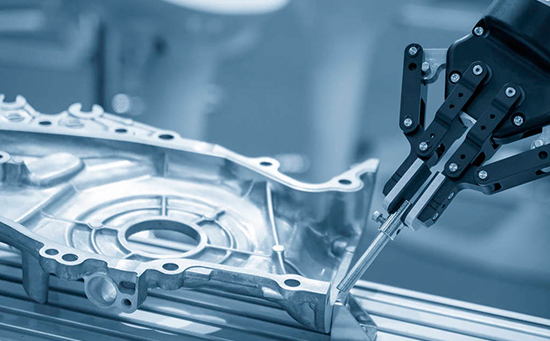

Our sound quality-control system makes sense that thousands of customers place their CNC machining orders in our company. The regular check and testing start from incoming materials to shipment, ensuring each part is produced accurately for your specifications.

We possess a comprehensive, standardized inspection report with every order to ensure quality metrics are being met, and offer a first-article inspection service on orders of 100+ units. We also have multiple certifications available on request, including but not limited to ISO9001 and ISO13485.

CNC machining is widely used across a wide range of industries. It is common in aerospace, automotive, consumer electronics, robotics, agriculture, and other fields that frequently use metal parts. It is also widely used in medical devices, household goods, energy, oil and gas, and other consumer applications. It is one of the most common processing methods in the manufacturing field.

NOBLE has offered ultra-precision CNC-crafted components for global industries including oil and gas CNC machining, medical instruments CNC machining, optical CNC machining, tool and die parts CNC machining, motorcycle components CNC machining, electronic enclosures CNC machining, automotive parts CNC machining, etc.