Insert Molding Services

Our Custom Insert Molding Services

NOBLE provides customized insert molding according to the specific needs of each customer. From prototype design to production, we provide customers with high-precision, stable-performance insert molding parts at competitive prices.

- ISO 9001:2015 and ISO13485-2016 Certificated

- Competitive & Affordable Price

- 24/7 Engineering Support

- 100% Part Inspection

- Fast Turn-Around Production

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Powerful Liquid Silicone Injection Molding Processes

Liquid silicone injection molding is a versatile and efficient solution for producing high-performance parts. NOBLE has advanced liquid silicone injection molding equipment and an experienced team of engineers to help you optimize your design, reduce injection molding costs, and get impeccable liquid silicone injection molded parts at competitive prices.The following are our powerful liquid silicone injection molding services

The two-component LSR material is injected into the mold under pressure, the LSR is heated and mixed, then injected into the mold and cured at a controlled temperature. After cooling and curing, the part is ejected. Due to its high precision and biocompatibility, it is widely used in the production of medical parts and automotive parts.

- State-of-the-art Equipment

- 10+ Years of Standard Liquid Silicone Injection Molding

- Competitive & Affordable Price

- Fast Turnaround in 7 days

It is to inject two different stages of liquid silicone materials into the mold and cool them separately to form a component that combines the characteristics of the two materials. Due to its aesthetic flexibility and improved performance, it is widely used in automotive and medical parts.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Two-Shot Liquid Silicone Injection Molding

- 100% Part Inspection

The preformed insert is placed in the mold cavity before injecting LSR, and the liquid silicone rubber is injected into the insert and bonds with it during the curing process. Due to its strong adhesiveness and strong adhesion, it is widely used to manufacture medical equipment and automotive parts.

- Competitive & Affordable Price

- 10+ Years of Two-Shot Liquid Silicone Injection Molding

- Countries Shipped

- 100% Part Inspection

A process that uses a mold with multiple cavities to produce multiple parts in a single cycle. It is widely used in high-volume manufacturing of medical device parts and automotive parts due to its higher production efficiency, consistency, and low cost.

- 10+ Years of Multi-Cavity Liquid Silicone Injection Molding

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

It uses a heated flow channel system to keep the silicone material at a high temperature in the flow channel, preventing it from curing prematurely and reducing material waste. Due to its high processing accuracy, short cycle, and high surface finish, it is widely used to manufacture medical equipment and automotive parts.

- 10+ Years of Hot-Runner Liquid Silicone Injection Molding

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

It uses medical-grade LSR that is biocompatible and safe for medical applications, similar to standard LSR injection molding. It is widely used in the manufacture of medical device parts and healthcare due to its sterilization compatibility and high performance.

- 10+ Years of Bio-Compatible Liquid Silicone Injection Molding

- Competitive & Affordable Price

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

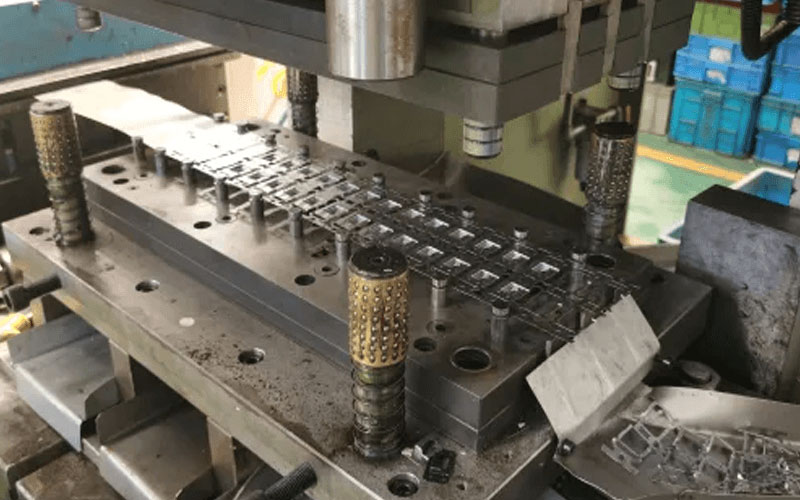

Our Robust Insert Molding Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

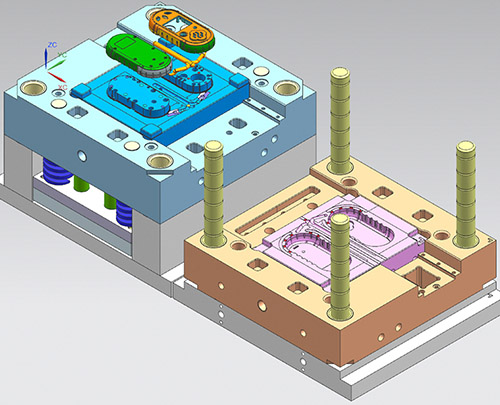

Mold Design & Engineering

Injection mold design is a key element of the injection molding process as it plays an important role in determining the quality and precision of the final injection molded parts. NOBLE has a professional design team to provide you with the best injection mold design solutions.

- 10+ years of Mold Design & Engineering

- State-of-the-Art Equipment

- 1-to-1 Quote Analysis

- Free DFM Feedback

- Strong R & D capability

- Free DFM and Mold Flow Analysis Report

Mold & Prototype Manufacturing

Once the mold design is approved, we begin manufacturing the mold. We then perform prototype injection molding to quickly and efficiently produce and test them for small batch production of plastic parts.

- 10+ Years of Mold & Prototype Manufacturing

- Thousands of resins to choose from

- Competitive & Affordable Price

- State-of-the-art Equipment

- 100% Part Inspection

- Fast Lead Time

Low-Volume & Medium Injection

NOBLE meets your small and medium batch injection molding needs through strict tolerance control, quality inspection, and complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium & Low Injection Molding

- Competitive & Affordable Price

- State-of-the-art Equipment

- Guaranteed Consistent Quality

- 100% Part Inspection

- Fast Turn-Around Production

Why Choose Us for Custom Custom Insert Molding Services?

NOBLE is dedicated to provide customized insert molding solutions from design to production. Our professional team quickly responds to your requirements.We provide competitive prices and strict standard production lines for high quality parts.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

What is Insert Molding Process?

Insert molding is a process that injecting plastic materials around another part so that forms a new part. As usual, the material of the inserted component could be plastic or metal. In the insert molding process, the insert is placed in the mold in advance, and then the machinist will inject plastic (thermoplastic resin is the common material) into the cavity. When cooled, parts are about to be packaged and delivered to customers.

Advantages of Insert Molding Process

As insert molding makes metal, plastics, and other materials form a combination together, improving the mechanical properties of the plastic parts or thermoplastic elastomer products. Besides, the advantages of insert molding are as follows:

Insert Molding Tolerances and Standards

For your convenience and to solve your problem more efficiently, refer to the following information to improve part manufacturability and reduce lead times. Let’s unlock the potential of your insert molding project.

| Standards | Metric Units | Imperial Units |

| Maximum Part Size | 800×1000×400mm | 31.50×39.37×15.75in. |

| Minimum Part Size | 2×2×2mm | 0. 08×0. 08×0. 08in. |

| Substrate Wall Thickness | From 0. 5 to 3mm | From 0. 20 to 0. 12 in. |

| Tolerance | +/- 0. 025 mm | +/- 0. 00098 in. |

| Inserts | Inserts can be female and male. They both can improve a product’s appearance and utility. | |

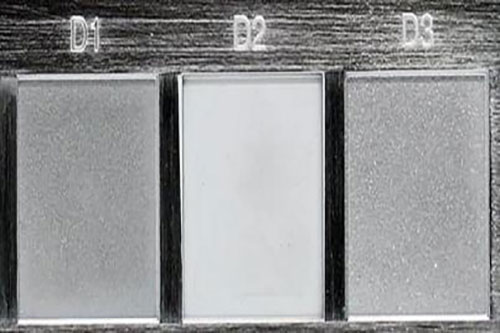

| Mold Validation | Provide T0, T1, T2 samples before mass production | |

| Inspection and Certification Options | First Article Inspection, ISO 9001, ISO13485 | |

| Lead Time | From mold making to sample delivery: 15-45 business days | |

Materials for Insert Molding

Advanced injection molding machines ensure up-to-date and available insert molding options. A range of materials are supported to support your custom requirements in various fields. There are some common materials:

Tooling Materal

High-tolerance CNC machined molds are required before the insert molding process can begin small or high-volume production. The most commonly used materials include:

| Tool Steel: | P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 |

| Stainless Steel: | 420, NAK80, S136, 316L, 316, 301, 303, 304 |

| Aluminum: | 6061, 5052, 7075 |

Plastic Materials

Plastic injection molding services offer a variety of materials with different properties such as impact strength, stiffness, heat resistance, and chemical resistance.

| ABS | Nylon (PA) | PC | PVC |

| PU | PMMA | PP | PEEK |

| PE | HDPE | PS | POM |

Additives and Fibers

Additives and fibers usually be added to standard plastic materials to improve their properties. Such as aesthetics.

| UV | absorbers | Colorants |

| Flame | retardants | Glass fibers |

| Plasticizers |

Inserts

The insert is put into the mold and then closed the mold. Plastic pellets will be plasticized. After the plastic has cured, the part is ejected from the mold, and the insert will be sealed into the part.

| Brass |

| Stainless Steel |

| Aluminum |

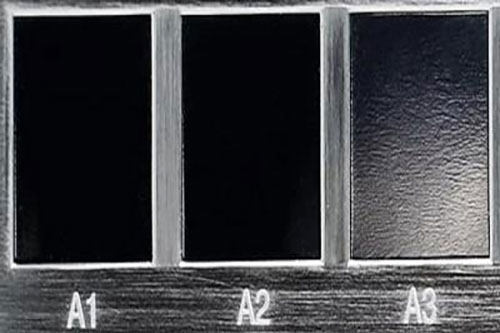

Surface Finishes for Insert Molding

Surface finishing is also be used to improve the part’s function and aesthetics. Common surface finishing is supported for your choice:

Glossy

A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts.

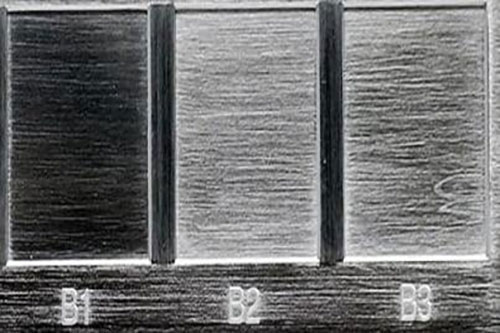

Semi-glossy

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture.

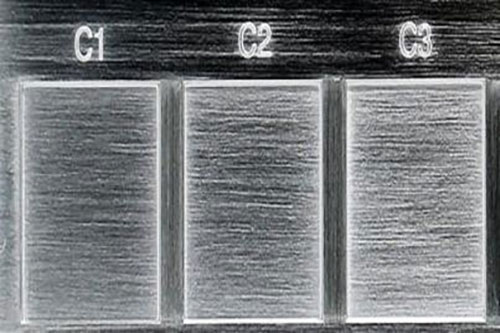

Matte

C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture.

Textured

D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish.

Custom Insert Molded Parts Display

Our custom insert molded parts are designed to enhance performance and durability. Check out our precision custom insert molded parts, including our valued customers’ precision parts.

See What Our Customers Say About Us

NOBLE’s insert molding solutions manufacture parts with different functional and aesthetical needs. You can check our valuable customer’s feedback.

Piscary Herskovic

Piscary Herskovic

NOBLE has been our quality supplier of insert molded parts. Fast delivery is essential for our business, and NOBLE always offers short lead time and competitive pricing. Andy responds quickly to all our emails and questions. This has improved our working relationship, and we continue to value this partnership.

Hari Mackenzie

Engineer

We asked NOBLE to fabricate parts for an acritical supplier demo, and you came through with a short lead time. Your work is alwayshigh quality, and we are grateful for your precision in insert molded parts. The help in checking our designs and material selection has also saved our company from making expensive errors.

We look forward to doing future projects with you guys.

Mark Alford

Vice President

From the instant and accurate quotation to the production process to the timely delivery of parts, NOBLE responded to our demands with complete professionalism. They handled every aspect of this insert molding project quickly and cost-effectively. We will surely work with them again in the future.

Kris Olarte

Vice President

I’ve worked with the NOBLE team in the past, they always do a perfect job. The responsiveness and ability to quote within a day make them my first choice to work with. They also are very good communicators and understand my design needs on a deep level or ask pertinent questions to ensure they do a perfect job.

Applications of Insert Molding

Because CNC machining can achieve high precision without changing the material structure with good manufacturing speed, it is becoming growing common as the range of machines, control systems, and tools for CNC machining continues to expand.NOBLE is dedicated to providing precision machining services for various industries and our precision CNC-crafted parts can be found in all areas of the industry, including.

Oil & Gas

Experts at NOBLE master the comprehensive knowledge of CNC machining for the oil field and gas industry paired with the assurance of high precision offered by top-notch CNC machines.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Insert Molding FAQs

In general, most moldable thermoplastic resins are compatible with the insert molding process. Usually, the insert is made of metal, usually brass, aluminum, or stainless steel.

Insert molding is a manufacturing process that involves molding a plastic or metal insert into a plastic part during the molding process. Here is a summary of how insert molding works:

1.A metal or plastic insert is placed into the mold cavity before the plastic material is injected. The insert is positioned in a specific location and held in place by the mold.

2.The mold is closed and the plastic material is injected into the cavity. The plastic material flows around the insert and fills the mold cavity, bonding with the insert and forming a composite part.

3.Once the plastic has cooled and solidified, the mold is opened and the finished part is removed.

Designing an insert molding involves several considerations to ensure that the final product meets the desired performance and aesthetic requirements. Here are some key steps to designing an insert molding:

Define the part requirements:Identify the functional, aesthetic, and performance requirements of the part, including the material properties, dimensional tolerances, surface finish, and assembly requirements.

Choose the insert material:Select the appropriate insert material based on the part requirements, such as the strength, stiffness, conductivity, and compatibility with the molding process and the plastic material.

Determine the insert geometry:Define the shape, size, and location of the insert in relation to the plastic part, taking into account the mold design, the injection molding process, and the assembly requirements.

Design the mold:Create a mold design that incorporates the insert and allows for proper plastic flow and bonding with the insert. The mold design should consider the molding process, the material properties, and the part geometry.

Optimize the molding process:Determine the appropriate molding parameters, such as the temperature, pressure, and cooling time, to ensure proper bonding between the insert and the plastic material. The molding process should be optimized to prevent defects, such as sink marks, voids, and warpage.

Test and validate the design:Perform testing and validation to ensure that the part meets the desired performance and aesthetic requirements, including dimensional accuracy, mechanical properties, and assembly fit.

Refine the design:Incorporate any necessary design changes based on the testing and validation results, and repeat the testing and validation process as needed.

Insert molding and overmolding are both plastic molding processes that involve molding one material over another to create a composite part. However, there are several differences between these two processes, including:

The placement of the insert material:In insert molding, the insert material is placed into the mold cavity before the plastic material is injected, whereas in overmolding, the plastic material is molded over the substrate material after it has been formed.

The purpose of the process:Insert molding is typically used to add strength, functionality, or aesthetics to the part, whereas overmolding is used to create a soft-touch grip, improve ergonomics, or add color or texture to the part.

The materials used:Insert molding typically involves metal or plastic inserts that are molded into a plastic part, whereas overmolding involves a variety of plastic materials that are molded over a substrate material.

The molding process:Insert molding can be performed using various molding processes, such as injection molding, compression molding, and transfer molding, whereas overmolding is typically performed using injection molding.

Insert molding is the process of molding or forming plastic parts around other non-plastic parts or inserts. The biggest difference between insert molding and overmolding is that overmolding involves two injections of material to form the substrate, while insert molding involves only one injection of molten plastic.

Here is a summary of how to insert molding works:

1.A metal or plastic insert is placed into the mold cavity before the plastic material is injected. The insert is positioned in a specific location and held in place by the mold.

2.The mold is closed and the plastic material is injected into the cavity. The plastic material flows around the insert and fills the mold cavity, bonding with the insert and forming a composite part.

3.Once the plastic has cooled and solidified, the mold is opened and the finished part is removed.