Sheet Metal Bending

Our Custom Sheet Metal Bending Services

Provide custom sheet metal bending services that exceed customer expectations at competitive prices. From prototype design to sheet metal bending manufacturing, we rely on our experienced team and advanced production equipment to ensure that you receive sheet metal bending parts with high precision and stable performance. Get a quote in minutes and sheet metal bending parts within days!

- Advanced Equipment & Competitive Price

- Tolerance Down to 0.001mm

- 10+ Years of Sheet Metal Bending Services

- ISO 9001 & ISO13485 Certified Factory

- 24/7 Engineering Support

- Lead Time As Fast As 3 Days

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

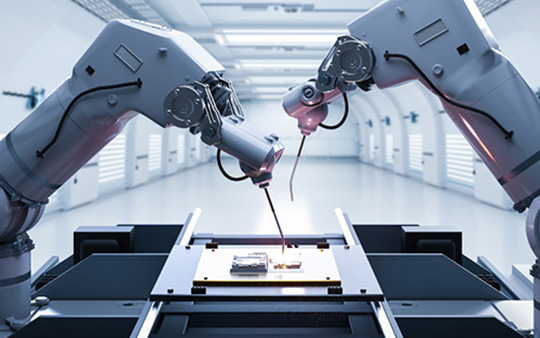

Our Powerful CNC Machining Processes

Providing custom CNC machining solutions at competitive prices, we choose from over 100 materials and 60+ surface finishes to ensure you receive high-precision, structurally complex, and performance-stable parts. Try our precision CNC machining services and become our next satisfied customer.

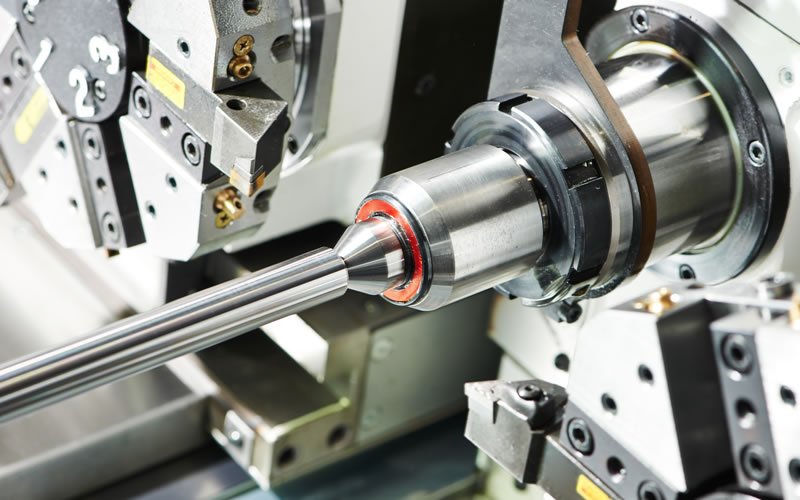

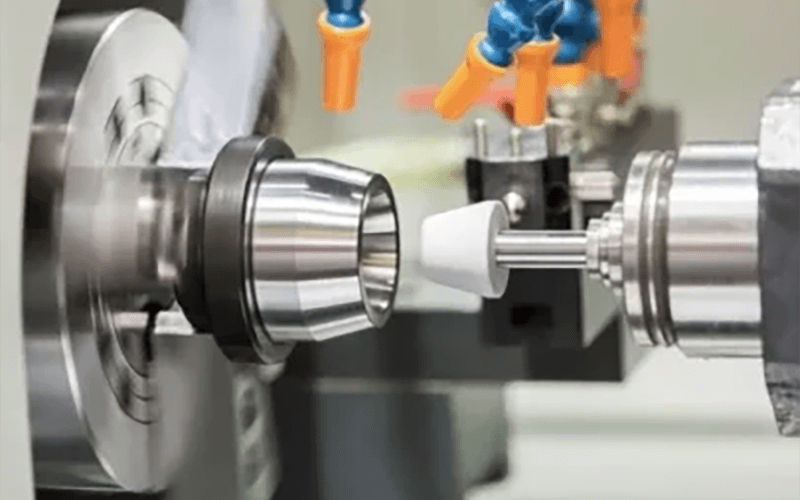

CNC turning is the process of cutting metal or plastic parts with cylindrical features from the outside of a bar with a rotating tool. The turning process can effectively manufacture circular parts and can be applied to create parts with complex internal and external geometries and various threads.

- Tolerances Down to ± 0.0003 In.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Milling Services

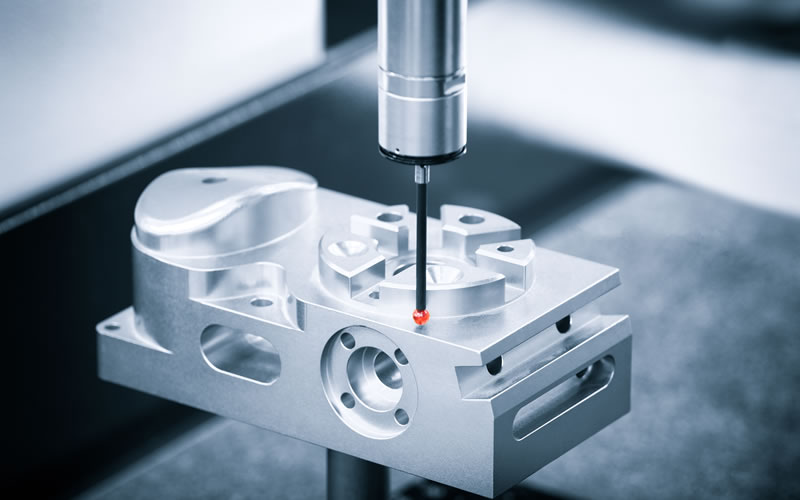

CNC milling is a subtractive process that uses 3-, 4-, and 5-axis milling machines and a variety of cutting tools to remove material from solid blocks of plastic and metal into final parts with varying geometries. With our 3-axis and 5-axis CNC milling services, you will be able to get milled parts with a tolerance of 0. 01mm.

- Tolerances Down to ± 0.0002 In.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- Quick Turn Turning Services

EDM and wire-cutting are CNC machining processes that use copper, graphite, or molybdenum wire to get the desired design for undercuts, sharp corners, and the removal of unnecessary material from workpieces. EDM is also frequently used to produce mold and rapid tooling.

- State-of-the-art Equipment

- 10+ Years of EDM & Wire-Cut

- Fast Turnaround in 7 days

- 1-to-1 Quote Analysis

Our CNC grinding machining service will be your best option if you need a very flat surface item or a round part with tolerances of OD and ID ±0.005mm for your production demands.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Grinding Services.

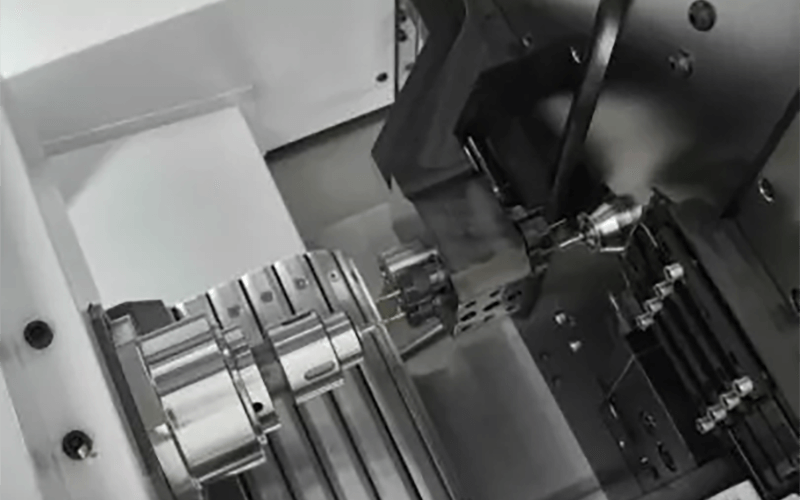

Swiss machining is a productive method for creating thin or complex parts. We can always cut the material that is near the workpiece holder by moving the workpiece as well as the active tooling. To prevent distortion in contrast to a conventional CNC lathe.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Swiss Machining Services.

We provide CNC routing services for prototypes and parts machining of soft materials like EPS foam, EVA, and wood in addition to regular milling services for parts made of engineering plastics or metals.

- 10+ Years of CNC Routing

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

Our Robust Sheet Metal Bending Capabilities

Sheet Metal Prototyping to Production

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Sheet Metal Prototype Machining

At NOBLE, you can get an online sheet metal fabrication quote and free design analysis within hours, and have your sheet metal fabrication prototype completed within days.

- State-of-the-art Equipment

- 10+ Years of Sheet Metal Manufacturing

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Rapid Sheet Metal Prototyping

With advanced production equipment and an experienced team of engineers, our sheet metal prototypes can be produced within a few days at a low unit cost, with strict tolerance control and a complete quality inspection process.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Batch Sheet Metal Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers large quantities of low-cost, stable-performance sheet metal parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Custom Sheet Metal Bending Service

Utilize advanced sheet metal bending technology and an experienced team of engineers to ensure precise, accurate metal bending angles to meet your exact specifications. Get bending, pipe bending, and roll bending parts at competitive prices, get an instant quote, and learn more about our custom sheet metal bending solutions and fast turnaround times.

Strong Metal Bending Capabilities

Offer sheet metal fabrication services such as bending, pipe bending, and roll bending at competitive prices. With advanced metal bending technology and an experienced team of engineers, we provide you with flexible material and surface finish options to meet your diverse sheet metal bending needs.

Competitive Pricing

Provide you with high-precision customized sheet metal bending services at competitive prices, from prototype design to sheet metal Fabrication, tailor-made metal bending solutions for you to ensure you get excellent metal bending parts. Our talented team can provide value-added solutions that exceed your budget.

Assured High Quality

NOBLE is an ISO13485-2016 and ISO 9001:2015 certified sheet metal machining manufacturer, each sheet metal part is thoroughly inspected, which guarantees that each sheet metal part is of top quality and meets your specific standards.

Customized Solutions

With advanced sheet metal bending equipment and an experienced engineer team, we provide customizable sheet metal bending solutions at competitive prices, specifying angles, bending radii, and other dimensions according to your design requirements to achieve seamless Customizable simple or multi-axis sheet metal bent parts.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Our Sheet Metal Bending Standards

ISO 9001:2015 and ISO13485-2016 Certificated, NOBLE ensures providing our customers with quality prototypes and production parts. Mature and advanced supporting metal bending machines and skilled technicians provide accurate and high quality metal bending services for rapid prototyping and production.

| Standards | Description |

| Maximum Part Size | 1.5 m x 1.5m |

| Metal Bending Forces | Up to 1000 tons |

| Bending Line Length | Up to 7200 mm |

| Bending Thickness | Up to 60 mm |

| General Tolerances | Our metal bending standards depend on ISO 2768. |

| Bend to edge/hole, single surface | +/- 0.254 mm (+/- 0.010 in.) |

| Bend Radius | Be equal to material thickness |

| Bend Angle | +/- 1° |

| Bending Cutting Area | Up to 4000 mm |

| Lead Time | 5 days or more |

Materials for Custom Sheet Metal Bending

Many premium materials in a range of thicknesses are compatible with NOBLE’S metal bending service. We have cutting-edge machinery at our facility that can bend materials with various mechanical and thermal qualities. See some of the materials you can use for your project.

Aluminum

Sheet metal machining often involves the use of aluminum due to its versatility, excellent thermal conductivity, and low resistivity. This material is cost-effective, highly productive, and generates less waste, making it an ideal choice for many applications. Additionally, aluminum is highly reusable, adding to its appeal in the metalworking industry.Subtypes: 2024, 5052, 5083, 6061, 6063, 6082, 7075.

Price: $

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Copper

Due to its strong malleability and ductility, copper is a widely utilized sheet metal fabrication material in numerous sectors. And it is also a good choice for sheet metal manufacturing because of its superior electrical conductivity and heat conduction qualities.Subtypes: C101, C110, C103, C27400, C28000. C36000.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Steel

For industrial applications, steel has a number of advantages, such as rigidity, durability, heat resistance, and corrosion resistance. Steel metal is the best material to use when creating intricate designs and elements that need to be extremely precise. Moreover, steel is inexpensive to deal with and could achieve a superior polishing surface. Subtypes: 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140,A36,ST37.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that contains a minimum of 10% chromium by weight. The material properties associated with stainless steel have made it a popular metal within a broad range of industries, including construction, automotive, aerospace and more. Within these industries, Stainless steel is versatile and is an effective choice for many applications.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Surface Finishes for Sheet Metal Bending

Outstanding surface finishing choices can enhance the surfaces of your bending components and final products. In order to improve the product’s aesthetic appeal and other qualities, a variety of surface finishing could be offered for you from NOBLE.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Sand Blasting

Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: ABS, Aluminum, Brass

Color: N/A

Texture: Matte

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

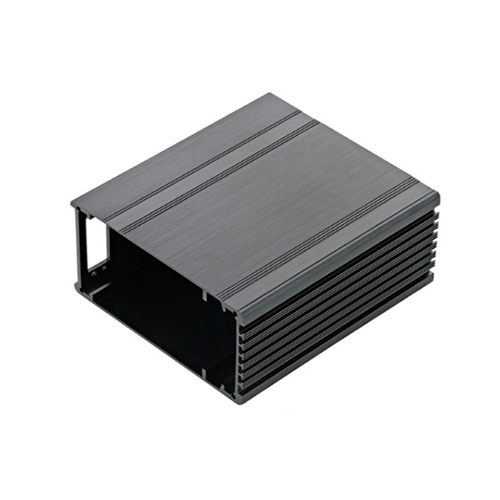

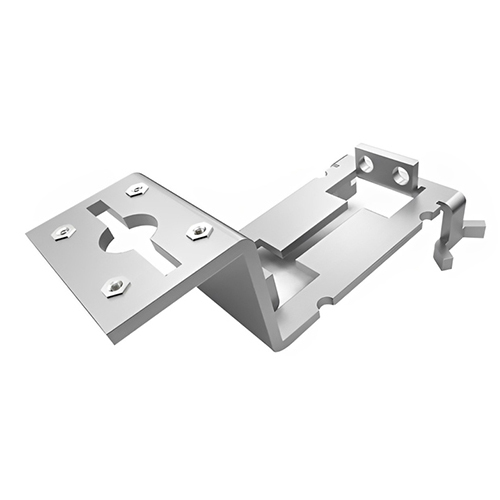

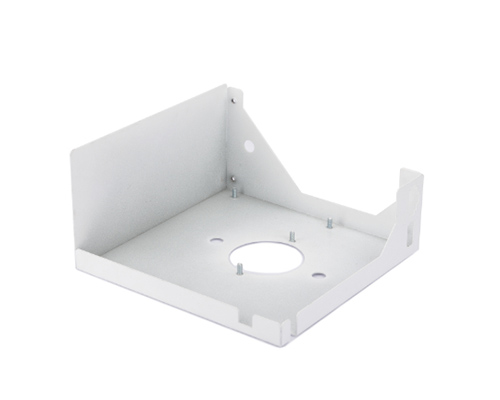

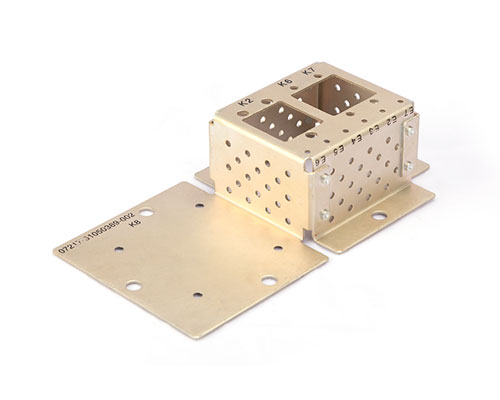

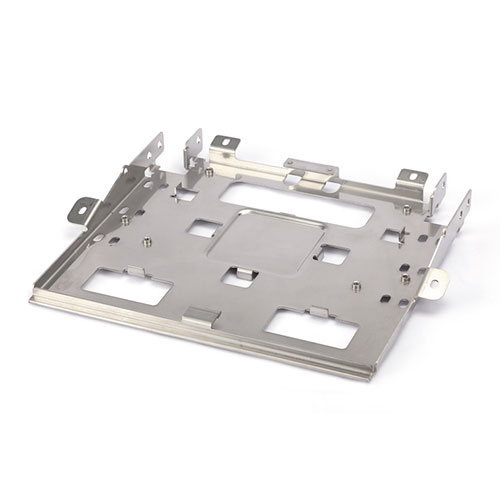

Custom Sheet Metal Bending Parts Display

Please browse through our extensive gallery showcasing sheet metal bending parts created by our esteemed customers.

See What Our Customers Say About Us

NOBLE has been engaged in Sheet metal fabrication services for over ten years and has served many overseas customers. Customers’ words are more substantively representative than the company’s statement–see the objective evaluation of our satisfied customers.

Mark Alford

Vice President

From the instant and accurate quotation to the production process to the timely delivery of parts, NOBLE responded to our demands with complete professionalism.They handled every aspect of this CNC machining project quickly and cost-effectively.We will surely work with them again in the future.

Piscary Herskovic

Product Designer

NOBLE has been our quality supplier of CNC machined parts.Fast delivery is very important for our business, and NOBLE always offers short lead time and competitive pricing.Andy responds fast to all our emails and questions.This has improved our working relationship, and we continue to value this partnership.

Hari Mackenzie

Engineer

We asked NOBLE to fabricate parts for a critical supplier demo, and you came through with a short lead time.Your work is always high quality, and we are grateful for your precision in machining components. The help in checking our designs and material selection has also saved our company from making expensive errors.We look forward to doing future projects with you guys.

Stefan Hohmann

Product Manager

My experience with NOBLE has been nothing but exceptional. From the start, the communication has been accurate and fast. Specificities of the design that may meet production difficulties are promptly pointed out with suggested solutions. The price of CNC machined parts is competitive. The QC of the final product is also excellent. There is no doubt that I will go back again.

What Is Sheet Metal Bending?

Effective sheet metal bending exerts enough force above the metal’s yield strength to deform the material without breaking. Using different types of sheet metal bending technologies, sheets can be bent into V-shapes, U-shapes, etc. Sheet metal bending can be used to achieve a variety of shapes and geometries for your desired application.

Advantages of Sheet Metal Bending

Sheet metal bending offers several advantages that make it a preferred method for shaping metal components.

Our Sheet Metal Bending for Various Applications

Sheet metal bending is a cost-efficient manufacturing technique used in various industries. NOBLE’s services have aided businesses in creating metal products such as auto parts and medical components.

Oil & Gas

The precise and reliable nature of sheet metal cutting makes it a valuable technique in the oil and gas industry for fabricating components and structures that meet stringent requirements for strength, durability, and safety.

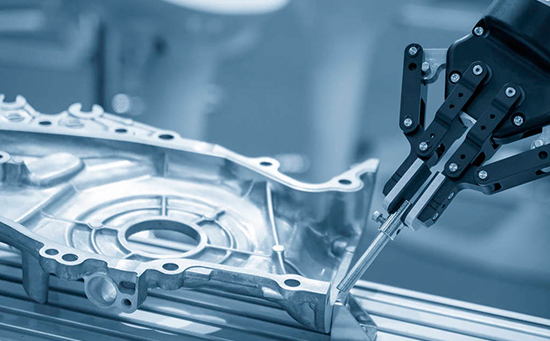

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Metal sheets can be cut in various ways in the automotive industry to produce a variety of robust vehicle parts. Such as fenders, hoods, roofs, and side panels are other vehicle-cutting components.

Aerospace

Precision and close tolerances are necessary for aerospace components. Some lightweight, space-ready component parts like bespoke interface panels, airfoils, and sensor enclosures could be machined by using custom metal cutting services.

Medical Devices

The process of metal cutting is readily available and offers a reliable way to produce long-lasting medical components that meet high standards of accuracy and quality. It can be utilized in the creation of scalpels, surgical instruments, and other essential medical equipment.

Robotics

Sheet metal cutting services are indispensable for precise, strong, and customizable robotics applications. They can create bespoke components that seamlessly integrate with the robot's design and function.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Sheet Metal Bending FAQs

Air bends, bottom bends, and impressions are the three main types.

Due to its wide range of uses and complete flexibility, carbon steel is the most commonly used material for bending in construction and OEM applications.

Sheet metal is a thin, malleable metal that maintains its shape even when bent. To achieve this, simply apply pressure to it with a stronger component.

Steel 0.5-0.8 inches can be bent laterally with a minimum radius of 2.5 times the thickness. For longitudinal bends, the minimum radius may need to be 3.75 times the thickness. Steel 0.8-2 inches thick requires thermoforming.

Some metals, such as tungsten and titanium, are very hard and less ductile, making them unsuitable for bending in most situations.

Yes, aluminum generally bends more easily than steel. It’s worth noting that the specific alloy and condition of the aluminum, as well as the type of steel, will affect the ease of bending. There are differences between each material category that affect its relative ease of bending. In addition, the thickness and geometry of the metal being bent and the bending process used also affect the ease and success of the bending operation.

The hardest metal is tungsten, and iron is also a hard metal. These metals resist bending and can withstand high temperatures without melting or weakening.