Sheet Metal Fabrication

Our Sheet Metal Fabrication Services

Our sheet metal fabrication provides various sheet metal capabilities (cutting, punching, bending, to welding services) that ensure high-quality parts and prototypes. Low-cost sheet metal fabrication solution provides on-demand production with fast turnaround.

- 10+ years of Sheet Metal Fabrication Parts

- ISO 9001 & ISO13485 Certified Factory

- Advanced Equipment & Competitive Price

- Instant Sheet Metal Fabrication Quotes

- Lead Time As Fast As 3 Days

- Provide Free DFM Report within 12 Hours

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Sheet Metal FabricationProcesses

Our sheet metal fabrication factory provides premium custom sheet metal fabrication services, utilizing extensive sheet metal stamping, sheet metal cutting, sheet metal bending, sheet metal welding, precision CNC machining, and assembly capabilities to produce high-quality sheet metal parts. NOBLE’s sheet metal fabrication manufacturers use advanced sheet metal fabrication technology and experienced engineers to ensure that you get unparalleled sheet metal fabrication parts with high precision and stable performance.

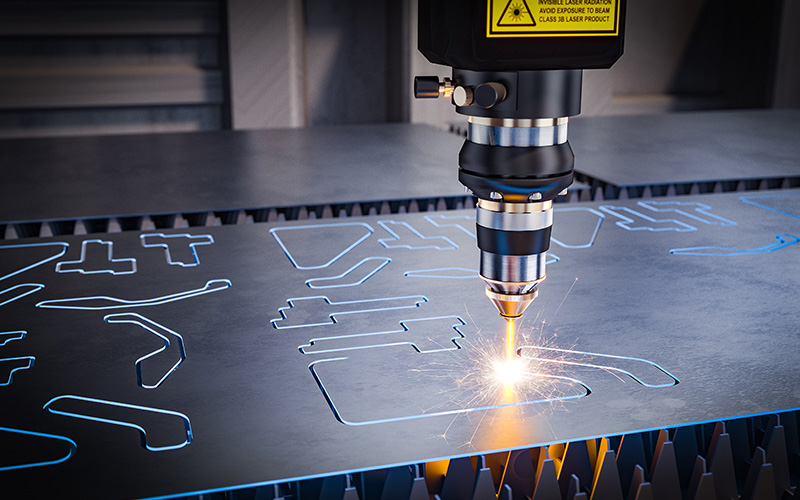

Sheet metal cutting is a manufacturing process used to separate large sheets of metal into smaller pieces. laser cutting, plasma cutting, and waterjet cutting are commonly used. It is commonly employed in industries such as automotive, aerospace, robotics, medical industry and etc.

- Quick, High Productivity

- Quick, High Productivity

- Fast Turnaround in 7 days

- Quick Turn Metal Cutting Services

Sheet metal stamping is a versatile and efficient manufacturing process that allows for the mass production of complex parts with excellent precision and cost-effectiveness. It is widely used in automotive, electronics, appliances, and aerospace, where it is used to produce components such as brackets, panels, enclosures, and chassis.

- Large-scale, Quick Production

- Quote Within 24 hours

- Fast Turnaround in 7 days

- Ouick Turn Metal Stamping Service

Sheet metal welding is a vital process that enables the fabrication of complex structures and components. It provides strength, durability, and integrity to sheet metal assemblies, allowing them to withstand various mechanical and environmental stresses.

- State-of-the-art Equipment

- 10+ Years of Metal Welding

- Fast Turnaround in 7 days

- 1-to-1 Quote Analysis

Sheet metal bending is a manufacturing process that uses dies to generate a V- shape, U-shaped, or channel shape along a straight axis in ductile materials. It is applied to shape stainless steel, steel, and aluminum parts, and rapid prototyping of custom sheet metal after the cutting process.

- Adapts to Various Materials

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Bending Services

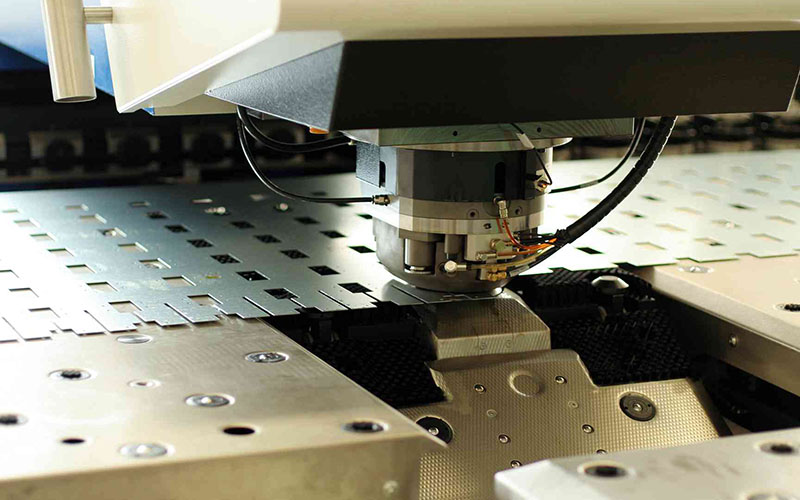

Sheet metal punching is a fast, precise, and versatile process for making holes or shapes in a variety of sheet metal, providing high efficiency and accuracy for large-scale products.

- 10+ years of Sheet Metal Punching

- ISO 9001 & ISO13485 Certified Factory

- Advanced Equipment & Competitive Price

- Suitable for Large-Scale Production

Sheet metal riveting provides a strong, permanent, and reliable method for joining metal sheets, offering durability and ease of assembly without the need for welding or complex tools.

- 10+ years of Sheet Metal Riveting

- Advanced Equipment & Competitive Price

- Uniform, accurate features produced

- Suitable for large-scale production

Our Robust Sheet Metal Fabrication Capabilities

Sheet Metal Prototyping to Production

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Sheet Metal Prototype Machining

At NOBLE, you can get an online sheet metal fabrication quote and free design analysis within hours, and have your sheet metal fabrication prototype completed within days.

- State-of-the-art Equipment

- 10+ Years of Sheet Metal Manufacturing

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Rapid Sheet Metal Prototyping

With advanced production equipment and an experienced team of engineers, our sheet metal prototypes can be produced within a few days at a low unit cost, with strict tolerance control and a complete quality inspection process.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Batch Sheet Metal Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers large quantities of low-cost, stable-performance sheet metal parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Sheet Metal Fabrication

NOBLE could handle everything from low-volume prototypes to high-volume production. Every sheet metal component is produced with precise specifications and quality standards. Why choose us? Here are 4 big reasons:

Quality and Accuracy Assurance

With certification ISO9001:2015of ISO 9001-2015 and ISO13485-2016, the quality and precision of sheet metal parts we produced will exceed your expectations.

Strong Manufacturing Capacity

NOBLE's factory has many excellent and advanced machines and experienced engineers. The wide range of internal capabilities can meet your requirements from design, and prototype to mass production of sheet metal parts.

Technical Proficiency in Sheet Metal Parts

Start your sheet metal fabrication project with NOBLE and you will always have access to our skilled experts and machinists to optimize your model design and get comments on manufacturability and cost savings.

Sheet Metal Engineering Support

NOBLE engineers provide 24/7 online engineering customer support for your custom sheet metal engineering and fabrication questions. This includes case-by-case advice to help you reduce costs early in the design phase.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Sheet Metal Fabrication Standards

To ensure part maneuverability and precision of fabricated prototypes and parts, our custom sheet metal fabrication services are in compliance with the ISO 2768-m.

| Dimension Detail | Metric Units | Imperial Units |

| Edge to edge, single surface | ±0.127 mm | ± 0.005 in. |

| Edge to hole, single surface | ±0.127 mm | ± 0.005 in. |

| Hole to hole, single surface | ±0.127 mm | ± 0.005 in. |

| Bend to edge / hole, single surface | ±0.254 mm | ± 0.010 in. |

| Edge to feature, multiple surface | ±0.762 mm | ± 0.010 in. |

| Over formed part, multiple surface | ±0.762 mm | ± 0.030 in. |

| Bend angle | ± 1° | |

| By default, sharp edges will be broken and deburred. For any critical edges that must be left sharp, please note and specify them in your drawing. | ||

Available Sheet Metal Fabrication Processes

Check out the specific advantages of each sheet metal manufacturing process and choose one for your custom part needs.

Laser Cutting

Laser cutting is a thermal cutting process that uses high-power laser to cut metals.

Thickness: Up to 50 mm

Cutting Area: Up to 4000 x 6000 mm

Plasma Cutting

CNC plasma cutting is suitable for cutting thicker sheet metals.

Thickness: Up to 50 mm

Cutting Area: Up to 4000 x 6000 mm

Waterjet Cutting

It is especially useful for cutting very thick metals, including steel.

Thickness: Up to 300 mm

Cutting Area: Up to 3000 x 6000 mm

Bending

It’s used to shape custom sheet metal prototypes after the cutting process.

Thickness: Up to 20 mm

Cutting Area: Up to 4000 mm

Materials for Sheet Metal Fabrication

Whatever the application and requirements of your sheet metal fabrication part, trust NOBLE to find the right sheet metal fabrication material. Some popular materials available for custom metal fabrication are outlined below.

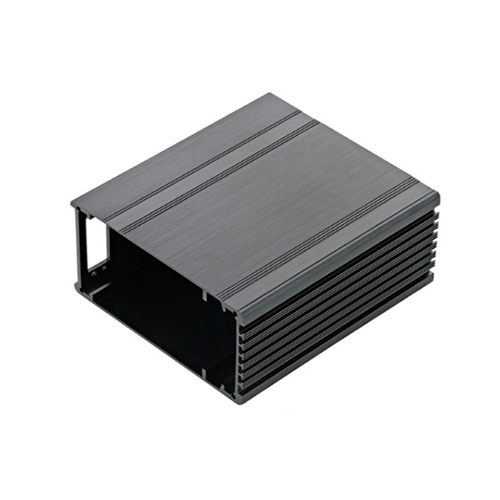

Aluminum

Commercially, aluminum is the most sought-after material for sheet metal manufacturing. Its popularity is due to its adaptive qualities and its high thermal conductivity and low resistance rates. Compared to steel—another common sheet metal material—aluminum is more cost-effective and has a higher rate of production. The material also generates the least amount of waste and can easily be reused.

Features: Info

Subtypes: 6061-T6, 7075-T6, 7050, 2024, 5052, 6063, etc

Process: CNC machining, injection molding, sheet metal fabrication

Tolerance: With drawing: as low as ± 0.005 mm No drawing: ISO 2768 medium

Applications: Light & economic, used from prototyping to production

Finishing Options: Alodine, Anodizing Types 2, 3, 3 + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing.

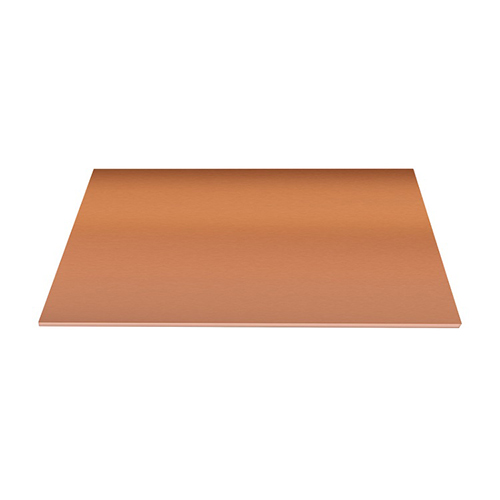

Copper

Copper is a broadly used sheet metal fabrication material in many industries as it offers good malleability and ductility. Copper is also well suited for sheet metal fabrication because of its excellent heat conduction properties and electrical conductivity.

Features: Info

Subtypes: 101, 110

Process: CNC machining, sheet metal fabrication

Tolerance: ISO 2768

Applications: Bus bars, gaskets, wire connectors, and other electrical applications

Finishing Options: Available as-machined, media blasted, or hand-polished

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Features: Info

Subtypes: 101, 110

Process: CNC machining, sheet metal fabrication

Tolerance: ISO 2768

Applications: Bus bars, gaskets, wire connectors, and other electrical applications

Finishing Options: Available as-machined,media blasted, or hand-polished

Steel

Steel offers a number of beneficial properties for industrial applications, including rigidity, longevity, heat resistance and corrosion resistance. Steel sheet metal is ideal for producing complex designs and parts that require extreme precision. Steel is also cost-efficient to work with and has excellent polishing properties.

Features: Info

Subtypes: 4140, 4130, A514, 4340

Process: CNC machining, sheet metal fabrication

Tolerance: With drawing: as low as ±0.005 mm No drawing: ISO 2768 medium

Applications: Fixtures and mounting plates; draft shafts, axles, torsion bars

Finishing Options: Black Oxide, ENP, Electropolishing, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing, Zinc Plating

Stainless Steel

Stainless steel is the low carbon steel that contains a minimum of 10% chromium by weight. The material properties associated with stainless steel have made it a popular metal within a broad range of industries, including construction, automotive, aerospace and more. Within these industries, Stainless steel is versatile and is an effective choice for many applications.

Features: Info

Subtypes: 303, 304L, 316L, 410, 416, 440C, etc

Process: CNC machining, sheet metal fabrication

Tolerance: With drawing: as low as ±0.005 mm No drawing: ISO 2768 medium

Applications: Industrial applications, fittings, fasteners, cookware, medical devices

Finishing Options: Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating

Finishing Options for Sheet Metal Fabrication

Choose from a wide variety of finishing options to alter the surface of sheet metal manufacturing components and products to improve their corrosion resistance, enhance appearance, and reduce cleaning time.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Sand Blasting

Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: ABS, Aluminum, Brass

Color: N/A

Texture: Matte

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

What Is the Sheet Metal Fabrication?

Sheet metal fabrication is a subtractive manufacturing process that involves forming thin sheet metal into parts by cutting, bending, folding, stamping, and assembling. Sheet metal can be cut, bent, or stretched into almost any shape, usually by cutting and burning the metal. Sheet metal parts are often exact and durable, which makes them particularly popular with engineers for end-use applications such as housings, brackets, and chassis.

If you have a legitimate need for custom sheet metal fabrication or outsourcing sheet metal fabrication to a reliable supplier in China, NOBLE may be your first choice. You can contact our team of knowledgeable engineers and mechanics for a quick and cost-effective solution for any part.

How Does Sheet Metal Fabrication Work?

The sheet metal fabrication processes start with removing materials from thin sheet metal stock placed on a flatbed following programmed part patterns to form desired shapes by cutting tools. This operation can be finished with a variety of subtractive machining processes. A sheet metal punch, shear, laser, waterjet, or plasma can generate additional features such as internal holes and edge features according to the part geometry. The second stage is material deformation. After being cut, the parts reach the press brake, forming into the final geometries with the forming process such as bending. The last stage is to assemble pieces of sheet metal or fit them together with other components not made from sheet metal into a complete product. In many cases, surface finishing operations are needed to enhance mechanical properties.

Advantages of Sheet Metal Fabrication

To ensure part maneuverability and precision of fabricated prototypes and parts, our custom sheet metal fabrication services are in compliance with the ISO 2768-m.

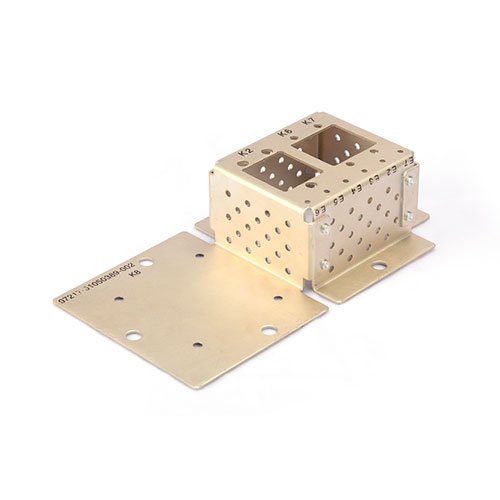

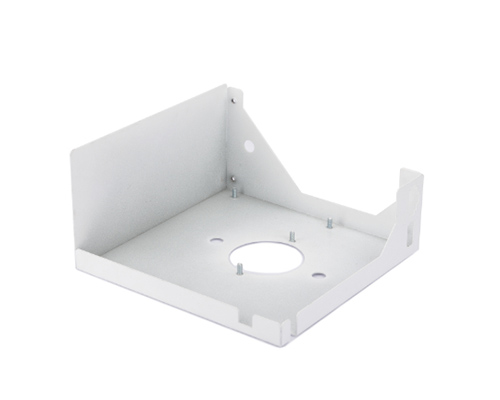

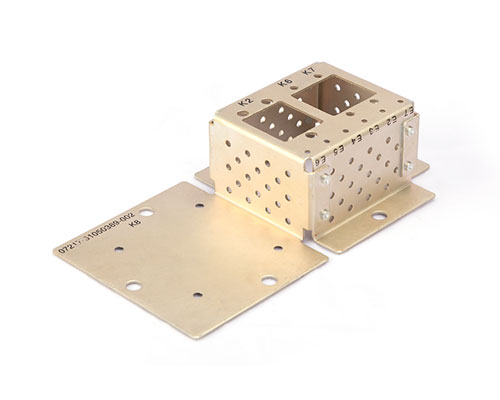

Custom Sheet Metal Fabrication Parts Display

For more than ten years, NOBLE has been focusing on providing sheet metal forming services for different metal materials and prototypes. The following are NOBLE customized sheet metal fabrication parts for customers.

See What Our Customers Say About Us

Customers’ feedback is more substantively representative than the company’s statement–see the objective evaluation of our satisfied customers. Feel free to customize the parts to fit your project and business!

Hari Mackenzie

Engineer

We asked NOBLE to fabricate parts for a critical supplier demo, and you came through with a short lead time. Your work is always high quality, and we are grateful for your precision in machining components. The help in checking our designs and material selection has also saved our company from making expensive errors. We look forward to doing future projects with you guys.

Raymond

Design Manager

Parts arrived for us today. Such beautiful milled parts, mate! Our team assembled the parts earlier which goes smoothly. Parts are as precise as we expected. Please pass my thanks to your production team. They are doing a great job! I am so glad that we found you guys online and eventually ordered from you guys. We are going to send you more CNC milling projects for quote soon.

Mark Alford

Vice President

From the instant and accurate quotation to the production process to the timely delivery of parts, NOBLE responded to our demands with complete professionalism. They handled every aspect of this CNC machining project quickly and cost-effectively. We will surely work with them again in the future.

Luc Szore

Mechanical Engineer

Hi Kevin, I’d like to thank you and everybody at NOBLE for contributing to the great service we received. You constantly handle our difficult CNC machining projects and offer instant quotation and free DFM analysis for the part design. Best of all, you show superior quality in short lead times. Our department supervisor confirmed that you will continue making these parts now. The quality is outstanding.

Sheet Metal Fabrication Applications

Sheet metal fabrication is a versatile manufacturing method for a wide variety of metal products across a variety of industries. This process is cost-effective for low-volume, high-mix prototypes, and high-volume production runs. NOBLE’s sheet metal machining services have helped businesses in different industries, whether metal auto parts or electronic equipment parts.

Oil & Gas

Experts at NOBLE master the comprehensive knowledge of CNC machining for the oil field and gas industry paired with the assurance of high precision offered by top-notch CNC machines.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Sheet Metal Fabrication FAQs

Sheet metal manufacturing tolerances are the acceptable deviations of sheet metal part features required for accurate and consistent fit and integration.

ISO 2768-mk is typically used on sheet metal parts to ensure proper control of geometric and dimensional elements. Below you will find 7 standard tolerance ranges for linear and angular dimensions, flatness and straightness, and cylindricity and roundness.

The selection of the cutting machine is determined by the gauge of the sheet and the material used, along with other key elements like delivery, tolerances, and geometric complexity as expected. You don’t have to figure out the type of cutting machine suiting your sheet metal as our experts clearly know what kind of equipment, technology, and even materials are best suitable for your project. Thus, just submit your 3D files online and get a professional solution from our experts in fabricating sheet metal quickly.

The flexibility of 5-axis CNC machining allows the creation of complex components with complex shapes and geometrical details. The stability of the machining tool also gives more consistent and smoother surface finishes. Therefore, you should choose 5-axis machining whenever you need to produce complex parts with tight tolerances.

Generally, the cost of using just a single cutting machine such as a laser cutter to cut a part will spend less than that of multiple forming processes, for instance, cutting, bending, and punching. But most sheet metal parts need to be machined with a combination of different forming processes, and the per-unit costs will reduce by large-volume quantities.

The tolerances of sheet metal fabrication are decided by the features and dimensional details of sheet metal parts necessary for consistent and precise integration and installation.

To ensure the accurate control of the variables affecting the part precision and manufacturability, our custom sheet metal fabrication services are in accordance with the ISO 2768-mk.

The costs of sheet metal fabricated parts or products depend in every respect including the design, geometric complexity, forming processes, surface finishing operations, and more. Besides these crucial factors, the material costs should be also considered.

Our quote online will include all of these factors and even variables in line with the manufacturability of sheet parts, so request a quote to get started with your project right now.

In general, a part that is cut, bent and punched will cost more than a part that is, for example, just cut using a laser cutter.

However, most sheet metal parts demand a combination of forming processes, and this will not increase the price by a drastic amount.

The type of cutting machine used depends on the chosen material and the gauge of the sheet, as well as factors like desired lead time and tolerances.

We know which projects need which equipment, so you don’t need to specify a particular cutting machine.