Surface Finishing

Our Custom Surface Finishing Services

Get instant online quotes for CNC machined parts in metals or plastics, from rapid prototyping to production. NOBLE provides precision CNC machining services, including milling, turning, grinding, EDM cutting, and surface grinding. Request an online quote today and experience lead times as short as 1 day.

- Advanced Equipment & Cost-Effective Price

- 10+ years of CNC Machining Parts

- ISO 9001 & ISO13485 Certified Factory

- Machining Parts As Fast As 2 Days

- Instant CNC Machining Quotes

- 24/7 Engineering Support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

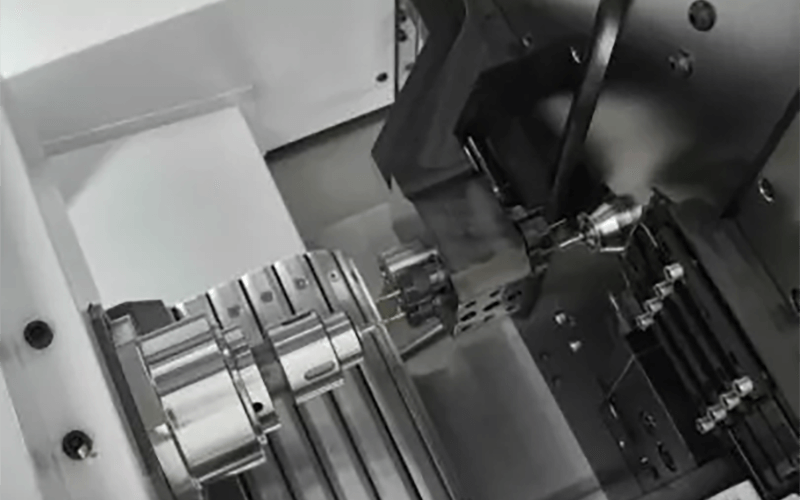

Our Powerful CNC Machining Processes

Providing custom CNC machining solutions at competitive prices, we choose from over 100 materials and 60+ surface finishes to ensure you receive high-precision, structurally complex, and performance-stable parts. Try our precision CNC machining services and become our next satisfied customer.

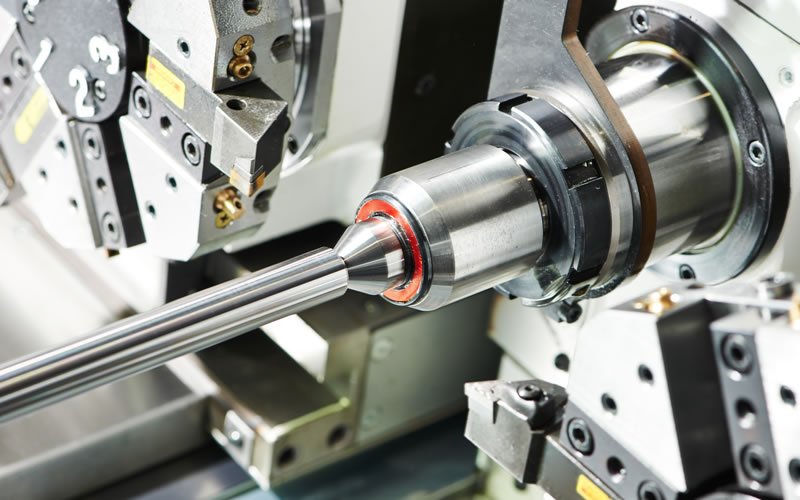

CNC turning is the process of cutting metal or plastic parts with cylindrical features from the outside of a bar with a rotating tool. The turning process can effectively manufacture circular parts and can be applied to create parts with complex internal and external geometries and various threads.

- Tolerances Down to ± 0.0003 In.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Milling Services

CNC milling is a subtractive process that uses 3-, 4-, and 5-axis milling machines and a variety of cutting tools to remove material from solid blocks of plastic and metal into final parts with varying geometries. With our 3-axis and 5-axis CNC milling services, you will be able to get milled parts with a tolerance of 0. 01mm.

- Tolerances Down to ± 0.0002 In.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- Quick Turn Turning Services

EDM and wire-cutting are CNC machining processes that use copper, graphite, or molybdenum wire to get the desired design for undercuts, sharp corners, and the removal of unnecessary material from workpieces. EDM is also frequently used to produce mold and rapid tooling.

- State-of-the-art Equipment

- 10+ Years of EDM & Wire-Cut

- Fast Turnaround in 7 days

- 1-to-1 Quote Analysis

Our CNC grinding machining service will be your best option if you need a very flat surface item or a round part with tolerances of OD and ID ±0.005mm for your production demands.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Grinding Services.

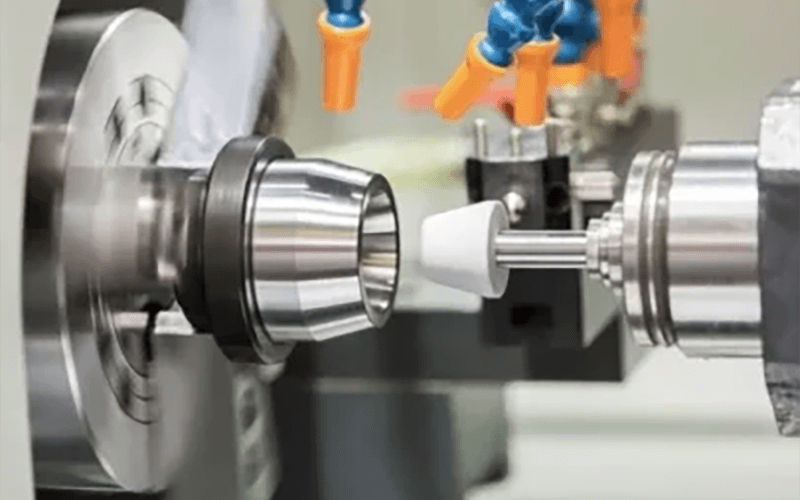

Swiss machining is a productive method for creating thin or complex parts. We can always cut the material that is near the workpiece holder by moving the workpiece as well as the active tooling. To prevent distortion in contrast to a conventional CNC lathe.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Swiss Machining Services.

We provide CNC routing services for prototypes and parts machining of soft materials like EPS foam, EVA, and wood in addition to regular milling services for parts made of engineering plastics or metals.

- 10+ Years of CNC Routing

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

Our Robust Surface Finishing Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Custom Surface Finishing Services

NOBLE has more than 10 years of experience in the surface finishing of parts and an experienced team, which can ensure fast delivery time and quality of components with complete confidence. For details, please refer to the four advantages of choosing NOBLE surface finishing services:

Economical Price

Our well-established supply chain and skilled surface treatment team enable us to match any client's budget or cost-effective solution.

Perfect Supply Chain

NOBLE has excellent suppliers who can help us receive the materials needed for continuous surface finishing, and at the same time strictly control the cost of each product within an affordable range, effectively reducing your project cost.

Strong Manufacturing Capabilities

NOBLE has advanced surface finishing equipment and experienced machinists, which make our surface treatment services far surpass competitors in the same industry and meet your immediate molding needs.

Wide Range of Materials

NOBLE has a number of excellent cooperative suppliers and a variety of surface finishing materials, which is the best choice for your surface finishing.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

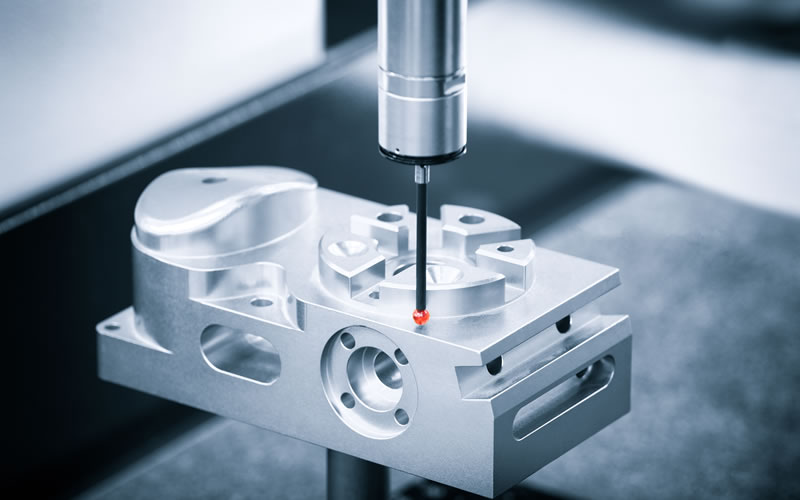

CNC Machining Tolerances and Standards

With precision CNC machining services, NOBLE is your ideal partner to create precision machined prototypes and parts. Our standard CNC machining tolerances for metals is ISO 2768-f and for plastics is ISO 2768-m. We can also achieve special tolerances as long as you indicate your requirements for your drawing.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 2000×1500×600 mm | 200×500 mm |

| Minimum Part Size | 4×4 mm 0. 1×0. 1 in | 2×2 mm 0. 079×0. 079 in |

| Minimum Feature Size | Φ 0. 50 mm Φ 0. 00197 in | Φ 0. 50 mm Φ 0. 00197 in. |

| Standard Tolerances | Metals: ISO 2768-f Plastics: ISO 2768-m | Metals: ISO 2768-f Plastics: ISO 2768-m |

| Hole Diameters | +/- 0. 025 mm +/- 0. 001 in. | +/- 0. 025 mm +/- 0. 001 in |

| Linear Dimension | +/- 0. 025 mm +/- 0. 001 in | +/- 0. 025 mm +/- 0. 001 in. |

| Edge Condition | Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | |

| Shaft Diameters | +/- 0. 025 mm +/- 0. 001 in | +/- 0. 025 mm +/- 0. 001 in. |

| Threads and Tapped Holes | Diameter: Φ 1. 5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 1. 5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

| NOBLE can produce threads of any specification and size required by our customers. | ||

| Text | Minimum width of 0. 5 mm, depth of 0. 1 mm | NOBLE can use laser marking to create standard text for CNC turned parts. |

| Lead Time | 3 business days | 3 business days |

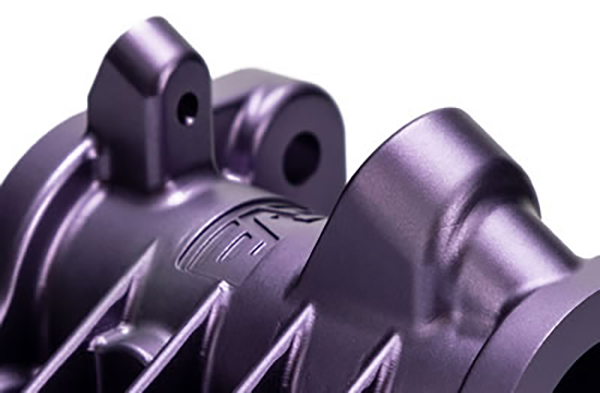

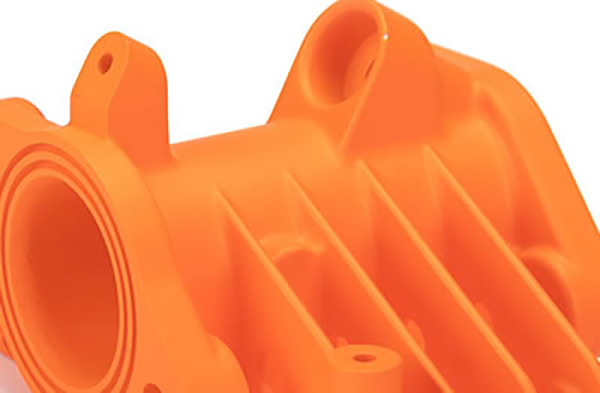

Our Surface Finishing Services

NOBLE has more than ten years of experience in surface treatment and excellent engineers, who are proficient in surface treatment of plastics, metals, and composite materials, and can turn your dream prototype or parts into reality.

As Machined

Coming out of the machine after machining, our parts are cleaned of any sharp edges and burrs while retaining marks. Without any added material, the part had a surface roughness of 3.2 μm (126 μin).

Band Blasting

Band blasting cleans the surface of any impurities and peels coating through the propelling of blast media streams over the parts.

Anodizing

To increase surface hardness and dissipate heat, we use anodizing techniques to enhance the look of parts and blend well for painting and priming.

Electroplating

Electroplating reduces metal cations in the electrolyte solution, producing a metallic coating on a metal surface. This process can be used for purposes of corrosion and wear resistance, as well as for decorative purposes.

Polishing

Working on metal and hard plastics, our polishing uses highly efficient machinery to get our parts between Ra 0.8~Ra 0.1 for a cleaner surface.

Powder coating

We apply a thin layer of protective polymer with the corona discharge phenomenon to give our part a lasting finish that protects from impacts and prevents wearing down.

Brushing

Our brushing technique uses abrasive belts over the material to create diverse patterns that match the parts’ structure and color.

Painting

Spray droplets can be dispersed uniformly or in fine amounts to cover a wide surface area and bring out greater color to the part.

Black Anodized

Adding layers to metallic surfaces like steel, our black anodized technique improves appearance while maintaining durability.

Alodine

We use chromate conversion coating or alodine to protect aluminum and other materials from corrosive elements, usually done before priming and painting parts.

Laser Carving

Helpful in brand recognition or parts organization, we use laser carving that applies various printing methods during full-scale production to quickly embed barcodes, lettering and logos on the parts.

Surface Finishing Specifications

Part surface finishing techniques can improve the aesthetics and function of your parts. Each surface treatment process has requirements, such as material, color, texture, and price. Below are the specifications of the surface treatment technologies offered by NOBLE.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

As-Machined

The standard finish for our parts, the “as machined” finish, has a surface roughness of 3.2 μm (126 μin), which removes sharp edges and deburr parts cleanly.

Materials: All materials

Color: N/A

Texture: Stain

Sand Blasting

Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: Aluminum, Brass, Copper

Color: N/A

Texture: Matte

Electroplating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: All metal materials

Color: Custom

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: Gold, silver, nickel, copper, brass

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: All materials

Color: Smooth, glossy finish

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

Painting

Painting involves spraying a layer of paint onto the surface of the part. Colors can be matched to a Pantone color number of the customer’s choosing, while finishes range from matte to gloss to metallic.

Materials: Aluminum, Stainless Steel, Steel

Color: Custom

Texture: Gloss, semi-gloss, flat, metallic, textured

Black Anodized

Coating is similar to alodine that is used for steel and stainless steel. It is used mainly for appearance and for mild corrosion resistance.

Materials: Steel, Stainless Steel

Color: Black

Texture: Smooth, matte

Alodine

Chromate conversion coating, more commonly known by its brand name Alodine, is a chemical coating that passivates and protects aluminum from corrosion. It is also used as a base layer before priming and painting parts.

Materials: Aluminum

Color: Clear, Gold

Texture: Same as before

Laser Carving

laser carving is a cost-effective way to add logos or custom lettering to your designs and is often used for custom part tagging during full-scale production.

Materials: All materials

Color: Custom

Texture: N/A

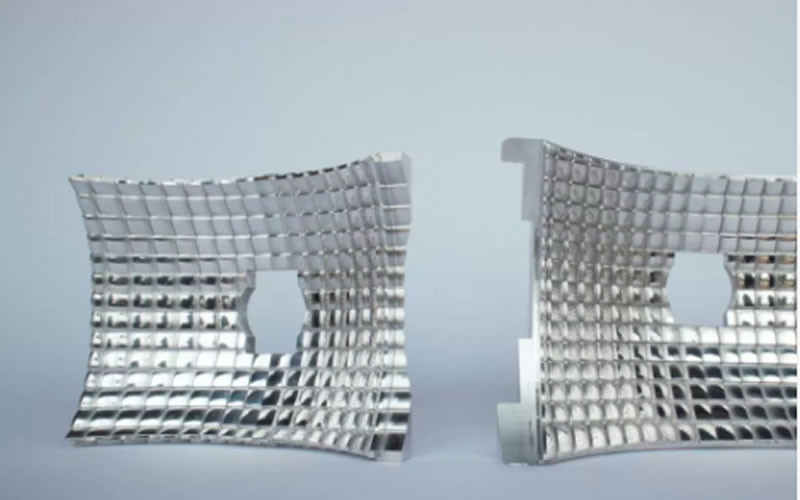

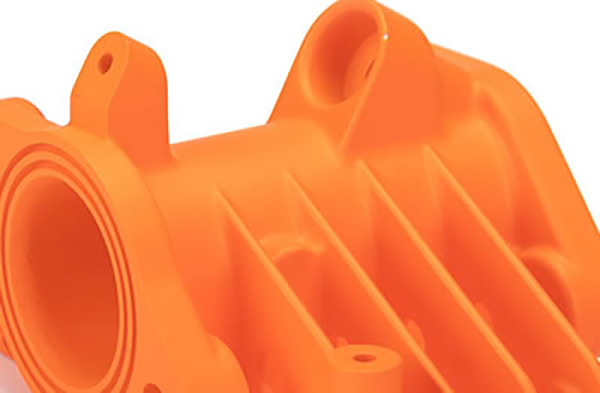

Custom Surface Finish Parts Display

Surface finishes can serve either a functional or aesthetic purpose. Check out our custom surface finish parts for our valuable customers.

What is Surface Finishing

Surface finishing refers to the different processes used to alter the surface of a finished product to give it a unique or desired look and feel. Different technologies are used to improve the appearance, adhesion, solderability, corrosion resistance, hardness, electrical stability, and many other properties of industrial components.

Advantages of Surface Finishing

No matter what manufacturing process you use, high-quality surface finishing services can improve the aesthetics and function of your parts. NOBLE offers various premium metal, composite, and plastic surface finishing services to bring the prototype or part of your dreams to life.

See What Our Customers Say About Us

NOBLE has more than ten years of experience in surface treatment, serving many medium and large customers. We consistently implement the principle of being customer-oriented. The following is how to comment on NOBLE for our satisfied customers.

Stefan Hohmann

Product Manager

My experience with NOBLE has been nothing but exceptional. From the start, the communication has been accurate and fast. Specificities of the design that may meet production difficulties are promptly pointed out with suggested solutions. The price of CNC machined parts is competitive. The QC of the final product is also excellent. There is no doubt that I will go back again.

Piscary Herskovic

Product Designer

NOBLE has been our quality supplier of CNC machined parts.Fast delivery is very important for our business, and NOBLE always offers short lead time and competitive pricing.Andy responds fast to all our emails and questions.This has improved our working relationship, and we continue to value this partnership.

Hari Mackenzie

Engineer

We asked NOBLE to fabricate parts for a critical supplier demo, and you came through with a short lead time.Your work is always high quality, and we are grateful for your precision in machining components. The help in checking our designs and material selection has also saved our company from making expensive errors.We look forward to doing future projects with you guys.

Mark Alford

Vice President

From the instant and accurate quotation to the production process to the timely delivery of parts, NOBLE responded to our demands with complete professionalism.They handled every aspect of this CNC machining project quickly and cost-effectively.We will surely work with them again in the future.

Surface Finishing Services Applications

Because CNC machining can achieve high precision without changing the material structure with good manufacturing speed, it is becoming growing common as the range of machines, control systems, and tools for CNC machining continues to expand.NOBLE is dedicated to providing precision machining services for various industries and our precision CNC-crafted parts can be found in all areas of the industry, including.

Oil & Gas

Experts at NOBLE master the comprehensive knowledge of CNC machining for the oil field and gas industry paired with the assurance of high precision offered by top-notch CNC machines.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Surface Finishing FAQs

In general, surface finishing processes encompass a wide range of industrial processes that remove, add, or alter the material, “finish” or complete the surface of a manufactured product.

Surface finishing of parts or prototypes will provide the surface smoothness of the parts, increase the anti-wear and anti-fatigue ability, increase or reduce the friction and wear of the matching parts, and improve the anti-corrosion ability and aesthetics of the parts.

NOBLE lists some common surface finishing:

painting and rolling

spraying.

electroplating.

adhesives.

sandblasting.

heat or pressure bonding.

printing.

NOBLE lists different materials that can use surface finishing:

| Material | Finishes |

| Papers and boards | Printing, waterproof coating, laminating, spot varnish, foil backing, foil or relief embossing, UV varnish |

| Textiles | Stain protection, waterproof coatings, mould and mildew protection, printing, dyeing, distressing (making it look old), flameproofing, crease resistance |

| Timber and wood | Painting, varnish, wax, stain, preservative, pressure treatment |

| Metals | Powder coating, dip coating, galvanising (coating iron or steel with zinc), electroplating (coating with a thin layer by electrolysis), shot blasting (cleaning or etching by firing a stream of high-speed metal beads) |

| Polymers | Polish, vinyl decals (sticky backed vinyl cut into decorative shapes), printing |

| Electronics | Protective insulation, lacquering, lubrication |

Some factors that can affect the quality of the surface finish include cutting-edge geometry, tool wear, built-up edge, and machine tool accuracy.

NOBLE’s engineers generally ensure no brush marks are left when painting the metal, usually removing any loose paint, buffing the metal surface, then applying a suitable oil-based primer, and sanding the metal surface until smooth to ensure your color blends evenly, Use a sprayer to paint the metal surface so that the paint on the metal part does not leave brush marks.