Latest news

-

What is Die Casting? Die Casting Overview

January 23, 2024 -

Guide for Vacuum Casting Process

January 16, 2024 -

Comprehensive Guide about Rapid Prototyping and Low Volum Manufacturing

January 09, 2024 -

Congratulations! Noble Passed The Certification Of "Shenzhen Specialized, Special And New Small And Medium Enterprises"

October 11, 2023

What is Precision CNC Machining?Gide for Begineers.

Contents

[]

What is Precision CNC Machining?

Precision CNC machining is a manufacturing method using computer-controlled machines to create high-precision parts and components. These parts have intricate geometries and tight tolerances. And CNC stands for "Computer Numerical Control." Because the software programs are edited to manage how the machine tools to move. Such as thespeed, direction, and depth ofmachine tools. As a result, it could produceprecise and consistent parts.Various movements can be achieved in the CNC machine. For example: drilling, milling, and turning. Precision CNC Machining also could machine various materials, like metal, plastic, or wood. Besides, precision CNC machining is popular in aerospace, automotive, medical, and electronics. High-quality parts and components with tight tolerances and finishes rely on it.CNC machining is an efficient and cost-effective method to manufacture complex parts. This cannot be achieved by using traditional machining techniques.

CNC Machining Process

1.Design CAD Model

Design engineers use software to design 2D or 3D models. Common software like AutoCAD, SolidWorks, Rhinoceros 3dmax, Pro-e, UG, and Catia. And 2D designs can also be converted to 3D designs according to product requirements. Engineers develop and refine CAD models to manifest critical features of the part,. Such as tolerances, construction lines, threads, and other parameters. This could help operators have a clear to machine the parts better.

2. Formatting for CNC compatibility

The CAD model won't be understood by CNC machines. So that the machine can understand it, you must convert the CAD model into a CNC-compatible file. Use online software providers or CAM programs like AutoCAD or Fusion 360 for this step.This software can transform data into a CNC-compatible format and provide parameters to the CNC machine. For example, the machining operation's rotational and linear movement, cutting order, toolpath, workpiece, machine speed, etc.

3. Set Up Parameter on CNC Machine

Once the CAM format designs are finalized, the next step is to prepare the machine for production. The operatior mount the workpiece onto the machine to fine-tune the machine tool. According to the materials and design of the workpiece, the operator will choose different machining tools to cut the workpiece. Besides, he will also set clamps apporopriately to achieve a better machining purpose. Such as setting the coolant levels.

4. Start to Machine the Part

Once the operator attaches the necessary cutting tools, the process will start. The automatic process will run until the computer program declares it as complete. To ensure quality parts,

different levels of inspection is adapted during or after the machining process.

Advantages of CNC Machining

High Accuracy

Precision machining could produce high accuracy and tight tolerance. Precision machining ensures perfect functionality in later stages. Thus, achieving excellent accuracy is crucial for these specific elements to work flawlessly.

Tight Tolerances

CNC is the go-to method for achieving tight tolerances. Tolerance, or dimensional accuracy, is crucial in ensuring that the machined parts match their CAD blueprints with minimal deviation. Specialized cutting tools and processes is adapted. CNC precision machining can effectively minimize these tolerances. Parts will more accurate compared to the original blueprints.

Consistency

CNC machines are highly automated and operate based on programmed instructions, which ensures that they can produce parts that are consistent in size, shape, and finish. This feature is particularly crucial for industries where precision and reliability are critical factors for optimal performance over time.

low production cost

CNC machining ensures accurate parts. This results in fewer defective products, reducing the scrap rate of parts. Moreover, automation reduces labor costs, and the technology saves material costs. CNC machining is thus a cost-effective option compared to any other alternatives.

versatility

Versatility is one of the advantages of CNC machining, allowing the machines to work with a vast range of materials and perform various operations. Below are a few examples that showcase the versatility of CNC machining:

Materials: CNC machines have the capability to work with a diverse range of materials, such as metals (including aluminum, steel, and titanium), plastics (including ABS, PVC, and polycarbonate), and wood. The flexibility in material options enables manufacturers to create parts that cater to the unique demands of their respective industries.

Operation:CNC machines have the ability to carry out a variety of operations such as milling, drilling, turning, grinding, and more. With the help of CNC milling machines, intricate shapes, and contours can be created in metal pieces, while CNC lathes can transform cylindrical materials into precise dimensioned shafts.

Prototyping: CNC machining offers the flexibility to manufacture parts in both small and large quantities, making it an excellent choice for prototyping purposes. Manufacturers can efficiently create a small batch of components for testing and perfecting their design before producing larger volumes.

Safety

CNC machines are equipped with safety features that ensure the well-being of operators. For instance, sensors are integrated into several machines that can recognize a broken tool or an incorrectly positioned part. The machine will then halt automatically to avoid mishaps.

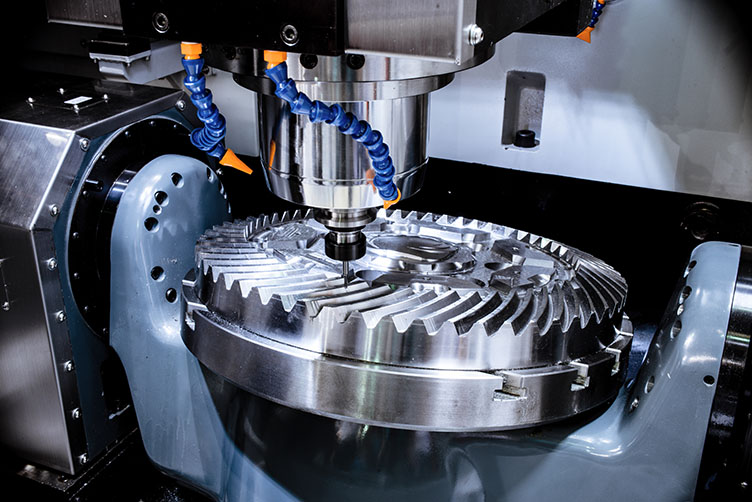

Types of CNC Machining Operations

In part manufacturing, CNC machining is a subtractive process that involves removing material from a workpiece to create the desired product. Some common CNC machining operations used for this purpose include:

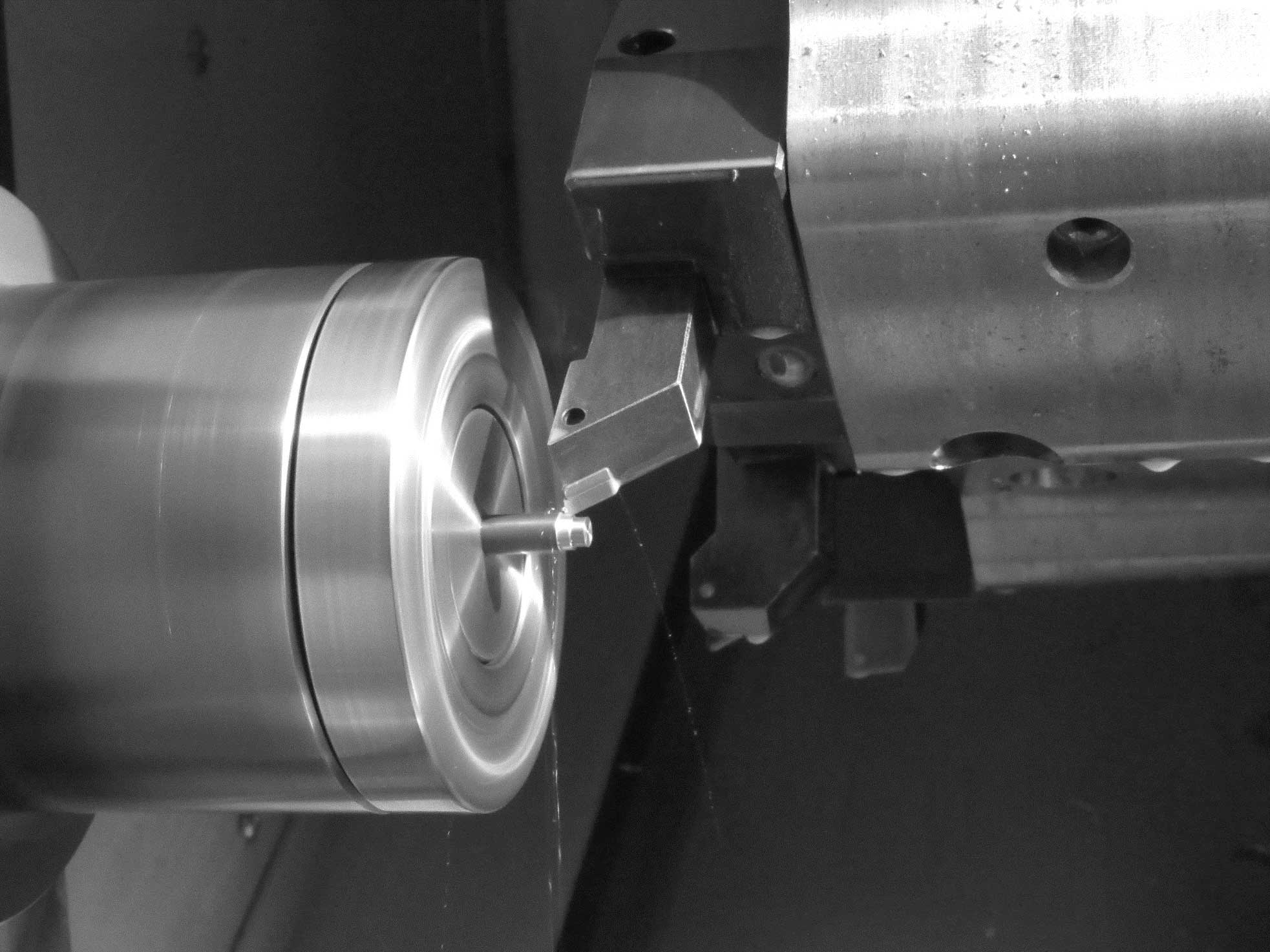

CNC Turning involves the rotation of a workpiece while a cutting tool is moved along its length to remove material. The tool is mounted on a carriage that can move along the X and Z axes, enabling it to travel in and out along the length of the workpiece. A tool holder holds the cutting tool in place and can be adjusted to change its position and angle. This process is often used to create cylindrical parts with various features such as grooves, threads, holes, and tapers. Cutting tools are typically made of high-speed steel, carbide, or diamond, depending on the material being machined and the desired finish. By removing material in a controlled manner as it moves along the part, the cutting tool creates the desired shape or design.

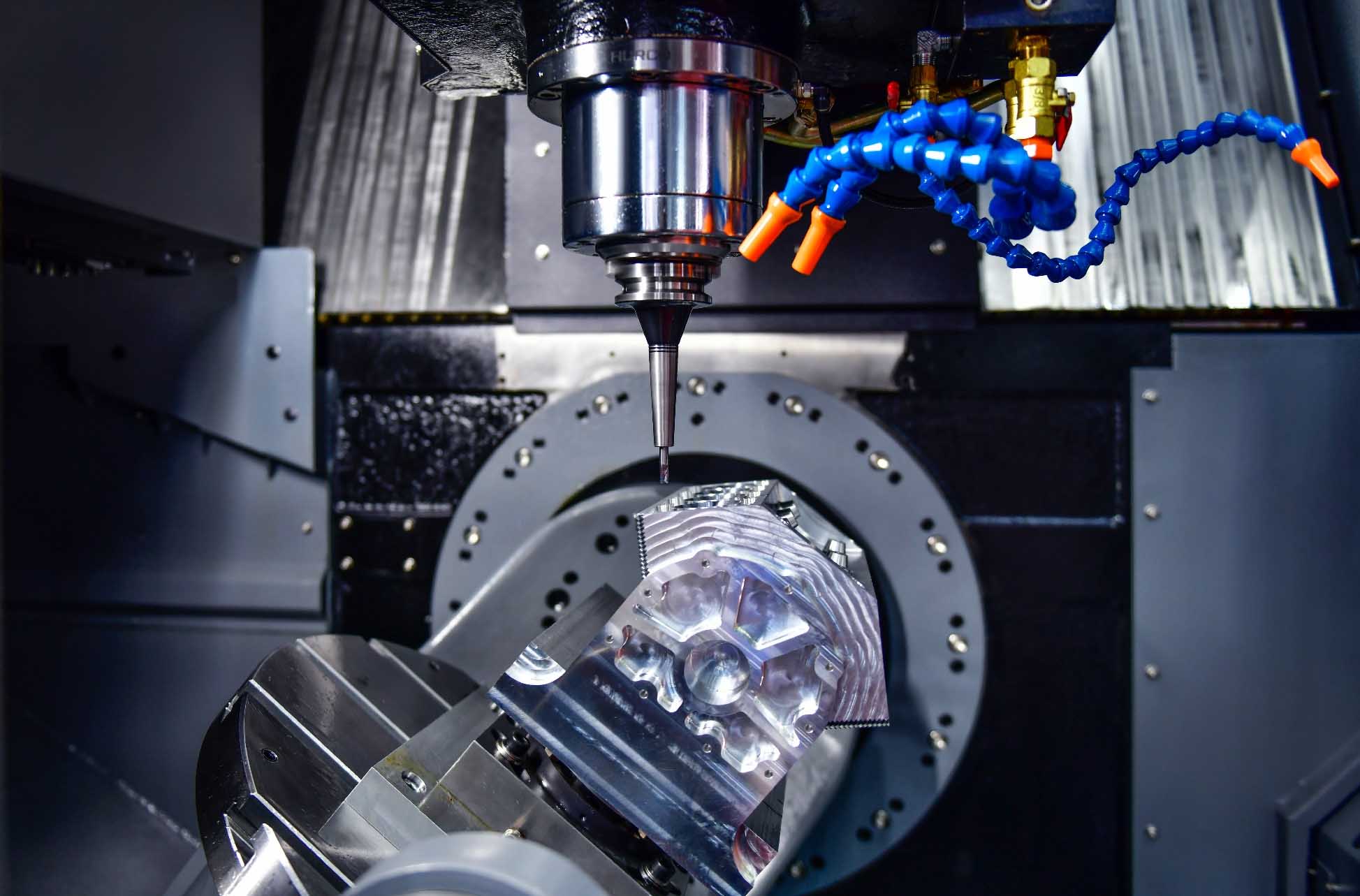

CNC milling is a rotary processing method that differs from CNC turning. In milling, the milling cutter rotates instead of the workpiece. There are two modes of relative motion in traditional milling. The first mode entails fixing the workpiece and relying on the milling cutter to rotate and translate. The second mode involves the milling cutter rotating simply, while the workpiece moves in three directions: front and back, left and right, and up and down.

CNC Drilling

CNC drilling is a machining process that utilizes rotating cutting tools to create round holes in a stationary workpiece. The drilling process is typically used for aesthetic purposes or to create space for screws and bolts. Drilling is a variation of routers or mills, and it can be combined into one machine with other methods of shaping materials.

Multi Axis CNC Machining

Multi-axis CNC machining is a type of CNC machining that involves the use of computer-controlled machines that can move along multiple axes to create complex shapes and geometries. One of the main advantages of multi-axis CNC machining is the ability to produce parts with complex geometries and features. Traditional CNC machining is limited to X, Y, and Z axes, making it difficult to produce parts with more complex shapes. Multi-axis CNC machines, on the other hand, can move cutting tools along multiple axes, allowing complex shapes and contours to be created.

3-axis machining

3-axis machining involves moving the cutting tool along the X, Y, and Z axes. This is the most basic form of multi-axis machining and is commonly used for simple parts and features. While it may not be suitable for producing highly complex parts, it is a cost-effective option for producing parts that do not require the advanced capabilities of multi-axis machining. For example, flat parts like plates, brackets, and covers can be produced with basic machining operations due to their simple shapes. Cubic parts, including blocks and cubes, also have simple features like holes and slots that can be machined using basic cutting tools. Additionally, cylindrical parts like shafts, tubes, and rods can be created through basic machining operations like turning and drilling. Parts with simple contours, like curved surfaces and chamfers, can also be produced through 3-axis machining using basic cutting tools and techniques.

4-Axis Machining

A form of CNC machining, 4-axis machining involves adding an extra axis of rotation (often called the A-axis) to the machining process. This allows the cutting tool to rotate around the part, which is useful for creating features such as angled holes. Some examples of parts that can be produced using 4-axis machining include:

1. Parts with angled holes: 4-axis machining can be used to produce parts with angled holes, such as those found in turbine blades and other aerospace components. The A-axis allows the cutting tool to be tilted at an angle, allowing holes to be machined at precise angles.

2. Curved parts: Four-axis machining can be used to produce parts with curved surfaces, such as impellers, propellers, etc. The A-axis allows the cutting tool to move around the part, allowing complex shapes and contours to be machined.

3. Parts with undercuts: 4-axis machining can be used to produce parts with undercuts, such as those in molds. The A-axis allows the cutting tool to approach the part from different angles, allowing the machining of features that are difficult or impossible to produce using traditional machining methods.

4. Parts with angular features: 4-axis machining can be used to produce parts with angular features such as chamfers and bevels. The A-axis allows the cutting tool to approach the part at an angle, allowing precise angular features to be machined.

5-axis machining involves adding two additional axes of rotation (often referred to as the A and B axes) to the machining process. This allows the cutting tool to move in multiple directions, allowing for greater flexibility and versatility compared to 3- and 4-axis machining. This is useful for creating complex shapes and contours. Some examples of parts that can be produced using 5-axis machining include:

1. Aerospace components: 5-axis machining can be used to produce complex aerospace components, such as turbine blades, engine parts, landing gear components, etc. Additional axes allow complex shapes and features to be created with high precision and accuracy.

2. Medical implants: 5-axis machining can be used to produce medical implants such as hip and knee replacements. Additional axes can create complex shapes that match the patient's body anatomy.

3. Molds and mold components: 5-axis machining can be used to produce molds and mold components such as cavities, cores, and inserts. Additional axes allow the creation of undercuts and other complex features, which are critical for producing high-quality molds and dies.

4. Auto parts: Five-axis machining can be used to produce auto parts such as engine blocks, cylinder heads, and transmission parts. Additional axes can create complex shapes and features, which are critical for high-performance automotive applications.

Materials for CNC Machining

Various materials are available for CNC machines, giving you options for rapid prototyping and custom production runs of complex parts. We provide instant quotes on more than 150 metals and plastics for your manufacturing needs, and you can even compare prices on different processed materials.

●ALuminum

Aluminum is a highly ductile metal, making it easy to machining. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

| Aluminum | |

| Price | $ |

| Lead Time | 3 days |

| Tolerances | ±0. 01mm |

| Max part size | 200 x 80 x 100 cm |

●Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

| Copper | |

| Wall Thickness | 0. 75 mm |

| Lead Time | 3 days |

| Tolerances | ±0. 01mm |

| Max part size | 200 x 80 x 100 cm |

●Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

| Brass | |

| Wall Thickness | 0. 75 mm |

| Lead Time | 3 days |

| Tolerances | ±0. 01mm |

| Max part size | 200 x 80 x 100 cm |

●Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

| Stainless Steel | |

| Wall Thickness | 0. 75 mm |

| Lead Time | 3 days |

| Tolerances | ±0. 01mm |

| Max part size | 200 x 80 x 100 cm |

●Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

| Titanium | |

| Wall Thickness | 0. 75 mm |

| Lead Time | 3 days |

| Tolerances | ±0. 01mm |

| Max part size | 200 x 80 x 100 cm |

●Plastics

Plastics are also a very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

| Plastics | |

| Machinable Material Types | POM, HDPE, PET, Nylon, PTFE, PVC, |

| Lead Time | 3 days |

| Tolerances | ±0. 01mm |

| Max part size | 200 x 80 x 100 cm |

Surface Finishes for CNC Machining

CNC machining leaves visible tool marks during the process of removing portions of the block's surface to create desired shapes. If you don't want as-machined parts, select a surface finishing for your custom parts. At NOBLE, we offer several common surface finishes that help improve functionality and aesthetics.

| Name | Description | Materials | Color | Texture | |

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish |

| Sand Blasting | Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass | N/A | Matte |

| Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, Stainless Steel | N/A | Smooth, Glossy finish |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Satin |

Application of CNC Machining

Application in the Automotive Industry

CNC machining is essential in the automotive industry, enabling producing high-quality and high-performance parts and components. It is beneficial to meet the demanding requirements of the modern automotive market. Details as following:

●Engine Components:

High-precision engine components are commonly used in CNC machining, such as cylinder heads, intake manifolds, and engine blocks. As these parts have complex geometries and require tight tolerances to ensure optimal performance. And CNC machining could make producing consistent and precise parts.

●Transmission Components:

Transmission components need to be highly precise and durable like gears, shafts, and housings. And CNC machining could produce intricate shapes and features to meet these requirements.

●Suspension Components:

Suspension components require high strength and stiffness to ensure optimal handling and stability. And CNC machining is a good way to deal with lightweight and high-performance designs. For example:

●Control Arms:

Control arms are a key component of a vehicle's suspension system. They connect the suspension to the vehicle's frame. And CNC machining could produce control arms with high precision and consistency,. It ensures that they fit and function correctly.

●Steering Knuckles:

Steering knuckles are another important component of a vehicle's suspension system. They connect the steering components to the wheel hub. CNC machining is used to produce steering knuckles with precise geometry and tolerances. And ensuring that they can withstand the loads and stresses of the steering system.

●Sway Bars: Sway bars (also known as anti-roll bars) are used to reduce body roll during cornering, improving handling and stability. CNC machining is used to produce sway bars with precise dimensions and stiffness properties, ensuring that they provide the desired level of performance.

Besides, suspension links, Strut Bodies,etc are also widely used CNC machining.

●Interior and Exterior Components: CNC machining is employed to manufacture both interior and exterior components with high-quality finishes and intricate designs., including dashboards, door handles, and grilles. CNC machining could produce these complex parts with minimal tooling costs.

Application in the Medical Industry

CNC machining plays a vital role in the medical industry. As it could achieve precision and accuracy to produce medical devices and instruments. Here are some of the ways CNC machining is used in the medical industry:

●Implants: CNC machining is used to produce a wide range of medical implants, from dental and orthopedic implants to cranial and spinal implants. These implants require high precision and biocompatibility to ensure proper fit and function within the body.

●Surgical Instruments: Surgical instruments such as forceps, scissors, and clamps are usually produced via CNC machining. These instruments require high precision and durability to ensure optimal performance during surgical procedures.

●Medical Devices: Medical devices from pumps and valves to diagnostic equipment and imaging machines are also could be produced. As CNC machining could ensure accuracy and consistent parts.

●Prosthetics: CNC machining is used to produce prosthetics such as artificial limbs and joints. These prosthetics require high precision and biocompatibility to ensure proper fit and function within the body.

●Dental Products: CNC machining is used to produce dental products such as crowns, bridges, and implants. These products require high precision and biocompatibility to ensure proper fit and function within the mouth.

Application in the Robotic Industry

CNC machining is versatile and essential in the robotic industry. It helps manufacturers to produce high-quality and high-performance robot components and systems with precision and consistency. As robotics technology continues to advance, CNC machining will continue to play a critical role to develop robotic products and manufacturing processes.

●Robot Components: Robot Components require high precision and durability to ensure optimal performance and reliability, including gears, bearings, shafts, housings, and frames.

●End Effectors: End effectors are attached to the end of a robotic arm. It is used to interact with the environment. CNC machining is used to produce end effectors with precise geometry and functionality. And it ensures that they can grasp, manipulate, and move objects with accuracy and consistency.

●Control Systems: Control systems require high precision and reliability to ensure accurate and responsive control of the robot.

And CNC machining produces the components and housings for robotic control systems, including sensors, actuators, and controllers.

●Prototyping: CNC machining is widely used in the prototyping stage of robotic development. Designers and engineers can use CNC machines to quickly produce prototypes of robot components and test their fit, form, and function before committing to mass production.

●Customization: CNC machining could customize robotic components and systems. These systems are tailored to specific robotic applications. This customization helps manufacturers to optimize robot performance and meet unique design requirements.

Application in the Areospace Industry

●Aerospace CNC Machining Parts

As a subtractive material process,CNC machining could assist in producing parts with partial hollows or complex geometries. It could reduce their weight. The CNC aerospace parts produced often include hydraulic manifolds, transmissions, fuel bodies, landing gear, electrical connectors, housings, etc.

Conclusion

Precision CNC machining is benificial to create intricate and precise parts.This process offers numerous benefits over conventional machining techniques, such as greater flexibility, quicker production times, and superior precision and accuracy. There are multiple forms of CNC machining available, including 3-axis, 4-axis, 5-axis, and multi-axis machining, each with its own distinct advantages and capabilities. By comprehending the definition, process, advantages, and types of CNC machining, businesses can make informed decisions about which machining technology to use for their specific requirements. Overall, precision CNC machining is a vital technology for countless industries, delivering the precision, accuracy, and efficiency essential for manufacturing high-quality parts and products.

At NOBLE, we specialize in offering expert CNC precision machining services. Our top-of-the-line 3-axis, 4-axis, and 5-axis CNC machining centers allow us to create customized parts that meet our client's specific requirements. Our experienced engineering team and dedicated quality inspection department work tirelessly to produce top-quality parts at the most reasonable prices.