Steel Injection Mold Tooling Service

Custom Steel Injection Mold Tooling Service

Customize steel injection mold tooling services for customers at competitive prices, from prototyping to manufacturing, and provide high precision, durable, and corrosion-resistant steel injection molds for efficient production in a short time.

- 10+ Years of Metal Injection Mold Experience

- 24H Instant Price & DFM

- Cost-effective and Quality Assured

- 100% Satisfaction Guarantee

- Competitive & Affordable Price

- High Quality and Consistency

Our Steel Injection Mold Tooling Capabilities

Steel is an important iron-carbon alloy with a carbon content ranging from 0.02% to 2.11%. It combines the high strength of iron with the hardness and wear resistance of carbon while maintaining excellent ductility and forgeability. Steel is the most commonly used material for injection mold tooling due to its ability to withstand high pressures, maintain dimensional stability, and offer superior wear resistance during the injection molding process.

Price | $$$ |

Lead Time | < 10 days |

Wall Thickness |

|

Tolerances | ±0.005″ (±0.125mm) |

Max Part Size | 200 cm x 80 cm x 100 cm |

Available Steel at NOBLE | Carbon Steel: 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, ST37 |

Characteristics of Steel Injection Mold Tooling Materials

Steel injection mold tooling and manufacturing is one of our main services. Below is some common information about steel, particularly in the context of steel injection.

| Features | Info |

| Subtypes | Q195,Q215,Q235,Q255,Q275,08 and 08F Steel,10 an,10F Steel,20 Steel,45 Steel,40Cr Steel,35CrMo Steel,42CrMo Steel |

| Process | injection mold tooling, sheet metal fabrication,die casting |

| Tolerance | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

| Applications | Fixtures and mounting plates; draft shafts, axles, torsion bars |

| Finishing Options | Black Oxide, ENP, Electropolishing, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing, Zinc Plating |

Pros and Cons of Steel Injection Mold Tooling

Strength and Toughness

Steel exhibits high strength and toughness, making it ideal for injection mold tooling. These properties allow steel molds to withstand the high pressures and thermal cycling encountered during the injection molding process, ensuring longevity and resistance to deformation or damage over time.

Cost-Effectiveness

Compared to some high-performance mold materials, steel offers a relatively lower price point, making it a more cost-effective option for manufacturing injection molds. Additionally, steel’s durability and recyclability contribute to cost savings over the long term, reducing the need for frequent mold replacements.

Excellent Machinability

Steel is highly machinable, allowing for precise shaping during the mold manufacturing process. Its ability to be easily formed into complex geometries makes it ideal for creating injection molds with intricate details. The high precision achievable with steel molds ensures high-quality molded parts.

Corrosion and Wear Resistance

Steel molds typically exhibit superior corrosion and wear resistance, which is essential for maintaining mold integrity over multiple production cycles. This resistance extends the lifespan of the mold, ensuring consistent part quality throughout the production run, even in harsh molding environments.

Versatile Applications

Steel is a versatile material, making it suitable for manufacturing injection molds for a wide range of industries, including automotive, aerospace, consumer products, and medical devices. It can be used to produce molds for both simple and complex parts, catering to various production needs.

Mold Cycle Time

Due to steel’s greater density and thermal conductivity, molds made from steel may require longer cycle times to heat and cool compared to molds made from lighter materials like aluminum. This extended cycle time can impact the efficiency of the molding process, particularly in high-volume production settings.

Energy Consumption

Steel molds typically require more energy to heat up and cool down during the injection molding process, given steel’s higher density and heat retention properties. This increased energy consumption can result in higher operational costs in production environments where energy efficiency is critical.

Corrosion Susceptibility

While steel generally offers good corrosion resistance, it can still be susceptible to corrosion if exposed to certain environments (e.g., high humidity or corrosive chemicals) without appropriate surface treatments. This can affect the mold’s performance and longevity unless it is properly treated or alloyed to enhance its corrosion resistance.

Tool Wear

Steel’s hardness and toughness, while beneficial for durability, can cause significant wear on machining tools during mold manufacturing. This can lead to increased tool wear and more frequent tool replacements, potentially increasing the cost and time required to manufacture the mold.

Accurate Delivery Time

NOBLE provides weekly progress reports to keep you informed of the progress.

Types of Steel for Injection Mold Tooling Materials

Steel has a wide range of mechanical properties, and the choice of these steels depends on the specific requirements of the injection mold tooling and the application’s need for strength, durability, and wear or corrosion resistance.

Carbon Steel Q195

With low carbon content, it offers good plasticity, toughness, machinability, and weldability but moderate strength. Commonly used for rolling thin sheets and coils, as well as cold- and hot-rolled galvanized and tinplate composite sheets for roofing panels, decorative sheets, general-purpose dust removal piping, packaging containers, etc.

Yield Strength(MPa): 195MPa

Elongation at Break(%): ≥33% (for thicknesses ≤16mm) ≥32%(for thicknesses>16-40mm)

Hardness(Brinell): 130-240HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: -20~500℃ at usually (Varies with heat treatment)

Carbon Steel Q215

Slightly stronger than Q195, it shares similar applications and is also extensively used for welded steel pipes, galvanized welded pipes, furnace supports, anchor bolts, bolts, round nails, wood screws, stamped iron hinges, and other hardware components.

Yield Strength(MPa): 215MPa (decreasing with increasing thickness)

Elongation at Break(%): ≥31% (for thicknesses ≤40mm)

Hardness(Brinell): 230HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: -40~200℃ at usually

Carbon Steel Q235

Balances strength, plasticity, and weldability well. It is the most widely used grade. Applications include rolled steel shapes and medium-thick steel plates for construction and engineering structures. It is also widely used for mechanical parts with moderate performance requirements.

Yield Strength(MPa): 235MPa

Elongation at Break(%): 26%

Hardness(Brinell): 170-210HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: 0~350℃ at usually

Carbon Steel Q255

Similar properties to Q235 but with slightly higher strength and lower plasticity. Less commonly used than Q235, primarily for riveted and bolted structures.

Yield Strength(MPa): 255MPa

Elongation at Break(%): 24% (for thicknesses ≤16mm)

Hardness(Brinell): HB220~250

Density(G/m³): ≈7.85 G/m³

Maximum Temp: -20~50℃ at usually

Carbon Steel Q275

Higher strength and hardness with good wear resistance. Used for manufacturing shafts, agricultural implements, wear-resistant parts, rail joint splints, base plates, wheels, rolls, etc.

Yield Strength(MPa): 275MPa

Elongation at Break(%): 17~22%

Hardness(Brinell): 270~400HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: 200~300℃ at usually

Carbon Steel 08F

Used for rolling thin sheets, deep-drawn products, oil drums, high-quality enamelware, and also for pipes, gaskets, and parts requiring low core strength such as carbonized and cyanided parts, welding electrodes, etc.

Yield Strength(MPa): 175MPa

Elongation at Break(%): ≥35%

Hardness(Brinell): 131HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: ≥200℃ at usually

Carbon Steel 10F

Suitable for cold deep-drawing products under 4mm thick, such as deep-drawn containers and artillery shells. Also used for boiler tubes, oil drum covers, steel strips, steel wires, welded parts, and mechanical parts.

Yield Strength(MPa): 185MPa

Elongation at Break(%): ≥30%

Hardness(Brinell): 137HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: ≥470℃ at usually

Carbon 20 Steel

Good weldability and plasticity, suitable for cold pressing and cold rolling. Often used for manufacturing parts and components like bolts, nuts, bearings, and pins.

Yield Strength(MPa): 355MPa

Elongation at Break(%): ≥25%

Hardness(Brinell): 156HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: -20~425℃ at usually

Surface Finishing Options for Steel Injection Mold Tooling

NOBLE has more than ten years of experience in surface treatments that can enhance the performance and aesthetics of steel injection mold tooling.

Glossy

A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts.

Semi-glossy

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture.

Matte

C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture.

Textured

D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish.

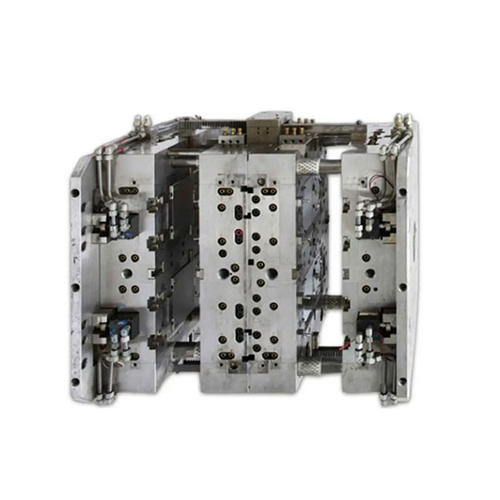

Custom Steel Injection Mold Tooling Parts Display

Check out our over ten years of custom steel injection mold tooling, including precision steel prototypes and parts from our valued customers.

Applications of Steel in Injection Mold Tooling

Steel is one of the most widely used materials in the manufacturing of injection mold tooling, with applications spanning a wide range of industries. Below is a closer look at industry-specific applications of steel in injection mold tooling:

Automotive Parts

Steel is used for injection mold tooling to create high-precision parts like gears, shafts, and interior components. Steel molds ensure durable, reliable parts for transmission systems, dashboards, and exterior body panels, meeting strict automotive safety and performance standards.

Aerospace Parts

Steel molds are crucial for creating aerospace components like fuselage parts and landing gear. Steel's strength and high-temperature resistance make it ideal for molds used in the aerospace sector, ensuring the production of lightweight, durable, and high-performance components.

Medical Devices

In the medical field, steel molds produce surgical instruments like scalpels and forceps. Steel’s durability and precision ensure that these critical components meet rigorous standards for safety and performance, supporting the production of reliable, high-quality medical devices.

Tool and Die Industry

Tool and high-speed steels are used for injection mold tooling and dies. Steel molds are essential for manufacturing precise plastic and metal parts, while tool steel ensures high-performance cutting tools for injection mold tooling, making it key to high-precision operations.

Oil and Gas

Steel molds are used to produce parts like drill bits and valves in the oil and gas industry. Steel’s high strength and resistance to high pressures and temperatures make it ideal for tooling that handles extreme conditions in this sector.

Machinery Equipment

Steel is used for injection mold tooling in heavy machinery. Molds made from steel produce components such as gears, shafts, and hydraulic systems for cranes, bulldozers, and excavators, ensuring precision and durability in large-scale, high-stress equipment.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!