Stainless Steel 3D Printing Service

Custom Stainless Steel 3D Printing Service

Stainless steel is a low-carbon steel with excellent qualities for a variety of industrial uses. Due to its high precision, high strength, and wide range of uses, it is a popular metal in various fields such as construction, automotive, aerospace, etc. NOBLE quickly customizes high-precision and complex stainless steel parts for customers at competitive prices.

- ISO 9001 & ISO13485 Certified Factory

- Advanced Equipment & Cost-Effective Price

- 10+ Years of Stainless Steel 3D Printing Service

- Provide Multiple Stainless Steel Materials Options

- Tight Tolerance of 0.001 mm

- 24/7 Engineering Support

Our Stainless Steel 3D Printing Capabilities

Stainless steel is an alloy composed of iron, carbon, and chromium. It is corrosion-resistant, high-temperature-resistant, high-strength, and easy to clean and sterilize. It is widely used in the construction, automotive, and medical industries. As a common 3D printing material, stainless steel can fully meet the needs of complex 3D printing projects due to its excellent machinability and consistency, and is deeply loved by stainless steel 3D printing manufacturers.

| Price | $ |

| Lead Time | <10days |

| Wall Thickness | 0.755 |

| Tolerance | ±0.125mm |

| Max part size | 200cmx80cmx100cm |

| Available Stainless Steel at NOBLE | Stainless Steel SUS201, Stainless Steel SUS303, Stainless Steel SUS304, Stainless Steel SUS316, Stainless Steel SUS316L, Stainless Steel SUS420, Stainless Steel SUS430, Stainless Steel SUS431, Stainless Steel SUS440C, Stainless Steel SUS630/17-4PH |

Characteristics of Stainless Steel 3D Printing Materials

Stainless steel parts 3D printing and manufacturing is one of our main types of business. The following is some common information about stainless steel types.

| Subtypes | Yield Strength (MPa) | Elongation at Break (%) | Hardness (Brinell) |

| Stainless Steel SUS201 | 275 – 380 | 50 | 147-210 |

| Stainless Steel SUS303 | 415-450 | 35-50 | 190-240 |

| Stainless Steel SUS304 | 215 – 505 | 40-70 | 170-220 |

| Stainless Steel SUS316 | 170 – 310 | 30-50 | 140-220 |

| Stainless Steel SUS316L | 170 – 290 | 40-50 | 140-190 |

| Stainless Steel SUS420 | 345 – 650 | 10-25 | 180-290 |

| Stainless Steel SUS430 | 275-450 | 20-30 | 150-200 |

| Stainless Steel SUS431 | 260 | 11 | 95 |

| Stainless Steel SUS440C | 450 – 1900 | 30 | 285-600 |

| Stainless Steel SUS630 | 725 – 1170 | 10 | 248-338 |

Pros and Cons of Stainless Steel for 3D Printing

Stainless steel is very durable, corrosion-resistant, and provides excellent strength for 3D printing, but it can be challenging to machine due to its hardness and tendency to work harden, which increases tool wear and 3D printing costs. As an experienced stainless steel parts manufacturer, NOBLE effectively controls costs for customers and allows you to obtain high-precision, stable, and complex stainless steel parts in a shorter time.

Heat Resistance

Certain grades of stainless steel, like 304 and 316, offer good heat resistance, enabling them to retain mechanical properties at elevated temperatures which is advantageous for parts exposed to high temperatures.

Strength and Durability

Stainless steel is known for its high tensile strength and durability, allowing for the production of parts that can withstand heavy loads and stress without deforming, especially in industries like automotive, aerospace, and medical.

Variety of Grades

Stainless steel offers a range of alloys (such as 303, 304, 316, and 17-4 PH),each with distinct properties tailored for specific applications, providing flexibility in selecting the best option for a given project.

Corrosion Resistance

Stainless steel’s high chromium content gives it exceptional resistance to corrosion and oxidation, making it suitable for parts exposed to moisture, chemicals, and extreme environmental conditions.

Aesthetic Finish

Stainless steel is often selected for its aesthetic appeal, as it can be polished to a high sheen and provides a sleek, modern look. This makes it a popular choice for consumer products and applications where visual quality is important.

Biocompatibility

Certain grades, like 316L, are biocompatible, making stainless steel apreferred material for medical devices, implants, and surgical instruments.

Burr Formation

Stainless steel can produce tough burrsduring 3D printing, which requires additional deburring processes to achieve smooth finishes and precise tolerances, adding time and cost toproduction.

Hardness and Work Hardening

Stainless steel is typically harder than other metals, which makes it more challenging to machine. it also tends to work hard, making it harder and more resistant to cutting as it is 3D printing, leading to increased tool wear and potential breakage.

Higher 3D Printing Costs

Due to its hardness and work-hardening properties, 3D printing stainless steel often requires slower speeds, specialized tools, and increased time, which leads tohigher 3D printing costs.

Tool Wear and Maintenance

Stainless steel tends to wear down cutting tools more quickly than softer metals, requiring frequent tool changes and maintenance, which adds to operational costs and downtime.

Heat Management

3D Printing stainless steel generates asignificant amount of heat, which, if notmanaged properly, can lead to warping, surface damage, and reduced precision. Coolants and lubricants are essential, but this increases the complexity and cost ofthe 3D printing process.

Limited Ductility in Certain Grades

Some grades of stainless steel, like 440C, have limited ductility and toughness, which can lead to chipping or cracking under high-stress 3D printing conditions, making them challenging to 3D printing for certain designs.

Types of Stainless Steel 3D Printing Materials

Stainless Steel parts 3D printing and manufacturing is one of our main type, below is some common information about brass.

Stainless Steel SUS201

SUS201 stainless steel is widely used in applications requiring moderate corrosion resistance, strength, and formability, including kitchen utensils, food processing equipment, automotive parts, and architectural structures.

Yield Strengh(MPa): 275-380

Elongation at Break(%): 50

Hardness(Brinell): 147-210

Density(G/m³): 7.9

Maximum Temp: 1080° F

Stainless Steel SUS303

SUS303 stainless steel is primarily used in applications requiring excellent machinability and moderate corrosion resistance, such as precision components, fasteners, shafts, and gears in automotive, aerospace, and industrial machinery.

Yield Strengh(MPa): 415-450

Elongation at Break(%): 35-50

Hardness(Brinell): 190-240

Density(G/m³): 7.9

Maximum Temp: 2550° F

Stainless Steel SUS304

SUS304 stainless steel is commonly used in applications needing high corrosion resistance and good formability, such as kitchen equipment, chemical containers, piping, and architectural structures.

Yield Strengh(MPa): 215-505

Elongation at Break(%): 40-70

Hardness(Brinell): 170-220

Density(G/m³): 7.9

Maximum Temp: 1500° F

Stainless Steel SUS316

SUS316 stainless steel is used in applications requiring superior corrosion resistance, especially against chlorides, making it ideal for marine equipment, chemical processing, medical devices, and food production machinery.

Yield Strengh(MPa): 170-310

Elongation at Break(%): 30-50

Hardness(Brinell): 140-220

Density(G/m³): 7.9

Maximum Temp: 1500° F

Stainless Steel SUS316L

SUS316L stainless steel is ideal for applications needing high corrosion resistance and low carbon content, such as medical implants, pharmaceutical and chemical processing equipment, and marine environments, where welding is frequently required.

Yield Strengh(MPa): 170-290

Elongation at Break(%): 40-50

Hardness(Brinell): 140-190

Density(G/m³): 7.9

Maximum Temp: 1500° F

Stainless Steel SUS420

SUS420 stainless steel is commonly used in applications requiring high hardness and moderate corrosion resistance, such as cutlery, surgical instruments, valves, and gears.

Yield Strengh(MPa): 345-650

Elongation at Break(%): 10-25

Hardness(Brinell): 180-290

Density(G/m³): 7.8

Maximum Temp: 935° F

Stainless Steel SUS430

SUS430 stainless steel is primarily used in applications that require good corrosion resistance and formability, such as kitchen appliances, automotive trim, and decorative architectural features.

Yield Strengh(MPa): 275-450

Elongation at Break(%): 20-30

Hardness(Brinell): 150-200

Density(G/m³): 7.75

Maximum Temp: 775 °F

Stainless Steel SUS431

SUS431 stainless steel is used in applications requiring high strength, good corrosion resistance, and toughness, such as pump shafts, marine hardware, and aircraft components.

Yield Strengh(MPa): 260

Elongation at Break(%): 11

Hardness(Brinell): 95

Density(G/m³): 2.7

Maximum Temp: 440 °F

Stainless Steel SUS440C

SUS440C stainless steel is used in applications needing high hardness, wear resistance, and moderate corrosion resistance, such as bearings, knives, valve components, and surgical instruments.

Yield Strengh(MPa): 450-1900

Elongation at Break(%): 30

Hardness(Brinell): 285-600

Density(G/m³): 7.75

Maximum Temp: 800°F

Stainless Steel SUS630

SUS630 stainless steel, also known as 17-4 PH, is used in applications requiring high strength, corrosion resistance, and good mechanical properties at elevated temperatures, such as aerospace parts, medical devices, and nuclear and petrochemical components.

Yield Strengh(MPa): 725-1170

Elongation at Break(%): 10

Hardness(Brinell): 248-338

Density(G/m³): 7.8

Maximum Temp: 900°F

Surface Finishing Options for Stainless Steel 3D Printing

Stainless steel can be finished using a variety of techniques, each of which can enhance the metal’s corrosion resistance, surface texture, and aesthetics. NOBLE can provide comprehensive surface treatment services to greatly improve the appearance, function, and durability of stainless steel 3D printing parts. Our rich and diverse stainless steel finishing services can ensure that you get stainless steel 3D printing parts with stable performance and excellent appearance. The following details the common surface treatments for stainless steel:

As Machined

Coming out of the machine after machining, our parts are cleaned of any sharp edges and burrs while retaining marks. Without any added material, the part had a surface roughness of 3.2 μm (126 μin).

Electroplating

Electroplating reduces metal cations in the electrolyte solution, producing a metallic coating on a metal surface. This process can be used for purposes of corrosion and wear resistance, as well as for decorative purposes.

Passivation

Passivation chemically removes contaminants from stainless steel, enhancing corrosion resistance by creating a protective oxide layer, crucial for longevity in harsh environments.

Powder coating

We apply a thin layer of protective polymer with the corona discharge phenomenon to give our part a lasting finish that protects from impacts and prevents wearing down.

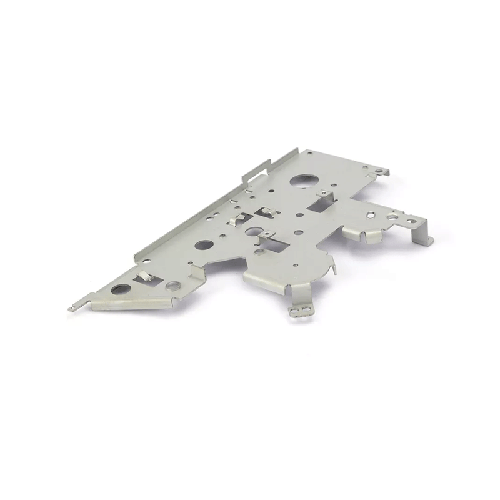

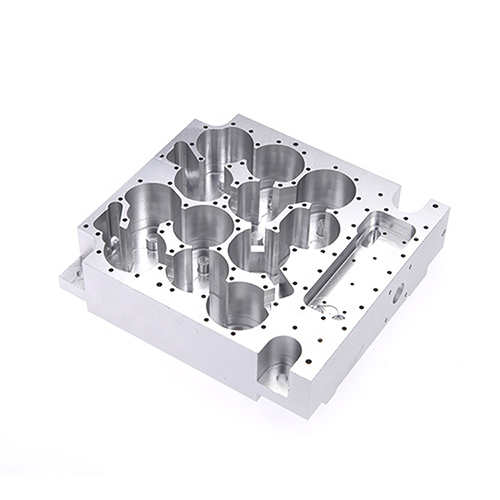

Custom Stainless Steel 3D Printing Parts Display

Check out our over a decade of custom stainless steel 3D printing experience, including precision stainless steel 3D printing prototypes and parts from our valued customers.

Applications of Stainless Steel 3D Printing

Stainless steel is a favorite among 3D printing manufacturers for its unique combination of strength, corrosion resistance, heat resistance, and aesthetics. These properties make it an ideal choice for 3D printing parts that must withstand harsh environments and meet strict regulatory standards.

Automotive Parts

Stainless steel’s durability, heat resistance, and corrosion resistance make it ideal for parts subject to high temperatures, mechanical stress, and exposure to moisture and chemicals. 3D printing ensures the precision required for tight tolerance parts such as fuel injectors and valve seats.

Aerospace Parts

The aerospace industry requires materials that can withstand high stresses, extreme temperatures, and corrosive agents. Machined stainless steel meets these needs and provides the precision required for safety-critical components.

Medical Devices

Biocompatible grades such as 316L resist corrosion, do not react with body fluids and can withstand repeated sterilization. Stainless steel 3D printing enables the intricate details and high tolerances required for surgical and dental applications, ensuring reliable performance.

New Energy

Stainless steel resists corrosion from seawater and a variety of chemicals, is strong enough to withstand high pressures, and can withstand extreme temperatures, all of which are critical to oil and gas equipment. Stainless steel 3D printing ensures the precision and reliability of parts that must withstand these challenging conditions.

Consumer Goods

Stainless steel’s beauty, strength, and corrosion resistance make it a top choice for products that are both functional and visually appealing. Stainless steel 3D printing provides high precision and clean surfaces, which are essential for producing complex consumer goods.

Electrical and Electronics Industry

Stainless steel’s durability, corrosion resistance and ability to dissipate heat make it ideal for protecting sensitive electronic equipment. Stainless steel 3D printing enables the complex designs and fine details required for electronic components, ensuring compatibility and durability for high-performance devices.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!