Rapid Prototyping Services

Our Rapid Prototyping Services

Rapid prototyping services at competitive prices Obtain impeccably high-precision parts through a variety of state-of-the-art manufacturing processes, includingCNC machining, 3D printing,vacuum casting, and sheet metal fabrication, and short lead times.

- 10+ Years of Sheet Metal Fabrication

- ISO 9001 & ISO13485 Certified Factory

- Advanced Equipment & Cost-Effective Price

- Impeccable Finish Treatment & Abundant Materials

- Various Rapid Prototyping Services

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Robust Rapid Prototyping Processes

NOBLE has 12 years of rapid prototyping experience and is proficient in various rapid prototyping processes. It can ensure your rapid prototyping manufacturing, assist you in optimizing the design of prototypes, choose the appropriate process to reduce costs, and achieve rapid mass production. We let you test a variety of materials and finishes so you can make an informed decision on how to move forward with your project. NOBLE has a range of rapid prototyping processes for you to choose from.

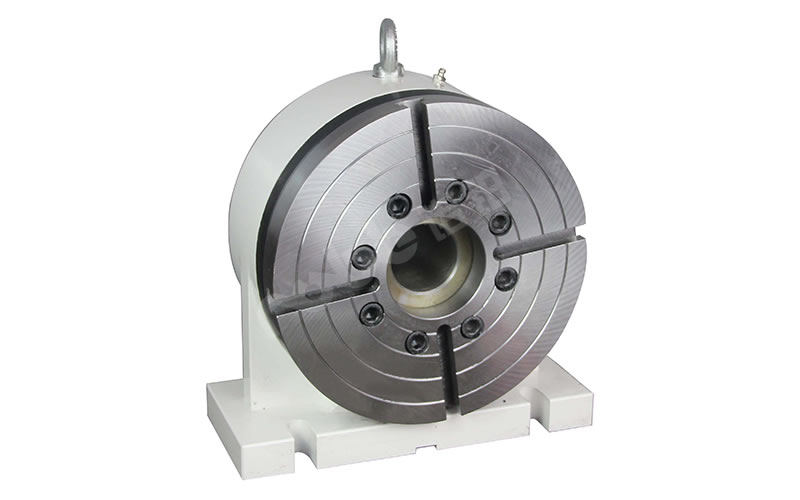

Our advanced 3 axis, 4 axis and 5 axis CNC machining help cut your product parts with great precision, ensuring your rapid prototyping runs smoothly while producing as many parts as possible.

- Tolerances Down to ± 0.0003 In.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Machining Services

Our rapid injection molding process results in an identical set of durable parts for testing and multiple backups. This process has a longer lead time, but it is usually worth it, especially for a product with strict material and mechanical requirements

- 1-to-1 Quote Analysis

- Competitive Price 30% Cost Save

- Functional Testing and Prototyping

- Free Dimensional Inspection Reports

NOBLE offers a wide variety of metals and alloys for your metal fabrication prototypes, including stainless steel, copper, and aluminum. We can also make two or more metal prototype designs at the same time.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- State-of-the-art Equipment

- Large-scale, Quick Production

This is the most common method used for rapid prototyping. This process requires no tooling, making it cost-effective and has a fast lead time. At NOBLE, we employ different 3D printing methods, including fused deposition model (FDM), selective laser sintering (SLS) and stereolithography (SLA), to ensure your prototype has high precision coupled with the best finish.

- Fast Turnaround in 7 Days

- Guaranteed Consistent Quality

- 10+ Years of 3D-Printed Parts

- 24/7 Engineering Support

NOBLE offers rapid vacuum casting for the manufacture of low-cost plastic parts. This fast prototyping method is similar to injection molding. However, the tools used for this fabrication are not very durable, making them ideal for small batches.

- 24/7 Engineering Support

- Lead Time As Fast As 3 Days

- 10+ Years of Vacuum Casting Service

- Instant Vacuum Casting Services Quotes

NOBLE has a strict die-casting process to ensure that we meet all your personalized requirements. Our highly skilled engineering team and state-of-the-art equipment consistently die-cast to manufacture durable prototypes and parts.

- 7/24 technical support

- 10+ Years of Die Casting

- Instant Die Casting Quotes

- Tolerance down to 0.001mm

Our Robust Rapid Prototyping Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Custom Rapid Prototyping Services

With 12 years of rapid prototyping service and an experienced team, NOBLE can ensure fast delivery time and the quality of your parts. Please see the four advantages of choosing NOBLE immediate prototyping services:

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

What is Rapid Prototyping?

Rapid prototyping is a technique specialized in the manufacture of high-quality physical models of design concepts in 3D. As an important basis for production or engineering testing, prototypes are useful during design development and improvement. Prototyping is fast and economical for individual companies and research institutions as they never need to invest in complex tooling equipment.

Our Rapid Prototyping Services

NOBLE has obtained remarkable achievements worldwide with our rapid prototyping services. Our engineering team with extensive knowledge and experience has utilized the latest prototyping technologies. With our prototyping centers, we are ideal for providing a comprehensive service to satisfy global customers’ requirements, timescales, and special needs. NOBLE can take your concepts or designs to reality production in just days with our proven prototyping technologies and processes.

Advantages of Rapid Prototyping

Rapid prototyping is a product development method that allows the production and iteration of product parts for evaluation and testing. Rapid prototyping services can confer abundant benefits for you and your business. Its outstanding advantages are as follows:

Rapid Prototyping Tolerances and Standards

With precision rapid CNC machining, injection molding, sheet metal fabrication, 3D printing, and vacuum casting services. NOBLE is your ideal partner to create precision machined prototypes and parts tolerance is down to 0.001.

Rapid Prototyping Process | Tolerance and Standrds |

Rapid CNC Machining | ±0.001mm; ISO 9001 & ISO13485 |

Rapid Injection Molding | ±0.005mm |

Rapid Sheet Metal Fabrication | ±0.05mm |

Rapid 3D Printing | ±0.01mm |

Rapid Vacuum Casting | ±0.001mm |

Die Casting Services | ±0.001mm |

Our Rapid Prototyping Capabilities

Rapid CNC Machining

For rapid prototyping of plastic and metal parts, CNC machining is the ideal product choice because we can create a prototype with all the precise detail you need and do it in short lead times.

Type: Tolerance

Linear dimension: ±0.025mm-±0.001inch

Hole Diameters: ±0.025mm-±0.001inch

Shaft Diameters: ±0.025mm-±0.001inch

Part size limit: 950 * 550 * 480 mm(37.0 * 21.5 * 18.5 inch)

Plastic Injection Molding

Our proven injection molding process is fit for the task when it comes to creating low-volume molds and plastic parts. Along with injection molding, we also apply secondary processing and other techniques to produce impressive products for your brand.

Standard capabilities: Description

Mold cavity tolerances: ±0.05 mm

Standard lead time: 15 business days or less

Part to part repeatability: ±0.1 mm

Production grade: 1-100,000 cycles

Rapid Sheet Metal Fabrication

NOBLE utilizes simplified sheet metal processing to produce metal parts. Our advanced sheet metal forming equipment and a 12-year-experienced team ensures short delivery times and strict quality standards

Dimension Detail: Description

Edge to edge, single surface /Edge to hole, single surface /Hole to hole, single surface: ±0.05 inch

Bend to edge / hole, single surface: ± 0.010 inch

Edge to feature, multiple surface /Over formed part, multiple surface: ± 0.030 inch

Production grade: 1-100,000 cycles

Rapid 3D Printing

NOBLE has the latest 3D printing technology to meet your fast 3D printing needs, such as SLA, SLS, FDM, etc. With our rapid prototyping capabilities and supply chain, you can be guaranteed custom parts within days.

Standard capabilities: Description

Min. wall thickness: 1.0 mm

Layer height: 50 – 300 μm

Max. build size:

250 * 250 * 250 mm (SLA),

420 * 500 * 420 mm (SLS),

500 * 500 * 500 mm (FDM)

Tolerance: ± 0.5% with a lower limit of ± 0.5 mm (± 0.020″)

Rapid Vacuum Casting

If you’re looking for a fast and reliable source of resilient plastic parts, NOBLE has you covered. Our vacuum casting process delivers consistent quality, finely detailed, and impressive plastic par.

Standard capabilities: Description

Maximum build size: ±0.025 mm-±0.001 inch

Standard lead time: Up to 20 parts in 15 days or less

Dimensional accuracy: ±0.05 mm

Layer thickness: 1.5mm – 2.5mm

Rapid Die Casting

Die casting is a process of manufacturing parts by pouring or forcing molten metal into steel modes to create various kinds of parts.

Standard capabilities: Description

Maximum build size: 300 mm × 650 mm

Standard lead time: Up to 20 parts in 15 days or less

Dimensional accuracy: ±0.05 mm

Layer thickness: 1.5mm – 2.5mm

Types of for Rapid Prototype

The rapid prototyping process is far-reaching, encompassing several materials, technologies, and industries. There are four different types of rapid prototypes.

Concept Model

This is one of the simplest types of prototypes. Also called a proof-of-concept prototype, engineers use the concept model to convey the basic idea of the design. Before use, this type of prototype undergoes multiple changes.

Display Prototype

Engineers develop this type of prototype to make it look similar to the final product. Most times, functionality is not a factor considered under the display prototype as the focus is mainly on appearance.

Functional Prototype

This prototype focuses on functionality and aims to enable engineers and designers to test the product to make modifications if any, for optimal functionality. The prototype developed here should behave the same way as the final product.

Pre-production prototype

This is the last type of prototype developed before production. There are two major purposes of this type of prototype. First, to validate the process chosen by the manufacturer for mass production, and second, to ensure the manufactured part functions optimally.

Custom Rapid Prototyping Parts Display

Get inspired by our custom rapid prototyping projects and contact us to Get Instant Quotes for rapid prototypes starting from 1 pcs.

See What Our Customers Say About Us

NOBLE has been engaged in rapid prototyping services for over ten years and has served many overseas customers. Customers’ words are more substantively representative than the company’s statement–see the objective evaluation of our satisfied customers.

Mark Alford

Vice President

From the instant and accurate quotation to the production process to the timely delivery of parts, NOBLE responded to our demands with complete professionalism.They handled every aspect of this CNC machining project quickly and cost-effectively.We will surely work with them again in the future.

Piscary Herskovic

Product Designer

NOBLE has been our quality supplier of CNC machined parts.Fast delivery is very important for our business, and NOBLE always offers short lead time and competitive pricing.Andy responds fast to all our emails and questions.This has improved our working relationship, and we continue to value this partnership.

Devin W

Vice President

I worked with another Chinese injection molding factory for eight years, and while the relationship was initially great, eventually became disappointed by quality issues, late delivery, and a complete lack of communication. Decided to give NOBLE a chance with a small order. Not only did they deliver on schedule, but they also did itwith100% accuracy and attention to detail. It was the same with my next order.

Nabil Karim

Engineer

NOBLE provides a refreshing perspective on product design. They have a knack for smart and efficient designsolutions. From ordering to tooling and prototyping, this company has the right manufacturing background whichsaves us a lot of cost and time. We noticed an immediate time and cost diference when we started designing with NOBLE.

Rapid Prototyping Services Applications

Because CNC machining can achieve high precision without changing the material structure with good manufacturing speed, it is becoming growing common as the range of machines, control systems, and tools for CNC machining continues to expand.NOBLE is dedicated to providing precision machining services for various industries and our precision CNC-crafted parts can be found in all areas of the industry, including.

Oil & Gas

Experts at NOBLE master the comprehensive knowledge of CNC machining for the oil field and gas industry paired with the assurance of high precision offered by top-notch CNC machines.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Rapid Prototyping FAQs

There are several situations that call for rapid prototyping. The first is that product development costs have become prohibitively high. Rapid prototyping costs less than traditional prototyping, reducing product development costs. Rapid prototyping is also required when you need to identify and evaluate product hazards and test functionality.

At NOBLE, the fast lead time for rapid prototyping is 5 working days. This is especially true when you use a reputed brand that offers rapid prototyping online services for your needs.

Rapid prototyping and 3D printing are completely different from each other. 3D printing is a technology that uses additive manufacturing to develop products. On the other hand, rapid prototyping is an umbrella term for a group of techniques used for the manufacturing of product parts from a 3D CAD model.

Rapid prototyping is a specialized manufacturing technique for high-quality physical models with 3D design concepts. Prototypes are very useful in design development and improvement process as a significant basis for production or engineering testing. Prototyping is quick and economic for both personal companies and research institutions in that they never need to invest in hard tooling equipment.

Speed and affordability are the key essences for rapid prototyping. As its name shows, it emphasizes a fast turnaround. So it’s expected to produce a physical part in a short time to validate the design, then capture business chances.