PMMA Injection Molding Service

Custom PMMA Injection Molding Service

We offer a full range of PMMA injection molding services with in-house molding capabilities and a vast network of resources across China. Our solutions cater to various industries, ensuring high-quality, durable, and visually clear components for prototypes and production runs.

- Instant Online Quote

- Competitive Price 30% cost save

- High Quality and Consistency

- Lead time As Fast As 3 Days

- 50+ Countries Shipped

- ISO 9001:2015 Certified 100% PMMA Part Inspection

Our PMMA Injection Molding Capabilities

NOBLE specializes in reliable injection molding part prototyping and production, ranging from simple to complex projects. We combine manufacturing expertise with advanced technologies and strict adherence to quality requirements to bring your ideas to life. Regardless of the end use of your PMMA parts, we can help you achieve your unique goals.

| Price | $$$ |

| Lead Time | < 6days |

| Wall Thickness | 0.045 in. – 0.140 in. (1.143mm – 3.556mm) |

| Tolerances | +/- 0.003 in. (0.08mm) with an included resin tolerance that can be greater than but no less than +/- 0.002 in./in. (0.002mm/mm) |

| Max Part Size | 18.9 in. x 29.6 in. x 8 in. (480mm x 751mm x 203mm) |

| Available PMMA at NOBLE | Extruded PMMA (Standard Grade), Cast PMMA (High-Quality Grade), Impact-Modified PMMA, UV-Resistant PMMA, Antistatic PMMA |

Characteristics of PMMA Injection Molding Materials

PMMA is lightweight, transparent, shatter-resistant, and offers excellent optical clarity and UV stability. Easily molded, it provides smooth finishes and versatility for complex shapes and custom designs. Our skilled design engineers ensure mold precision of up to 0.01mm through expert mold design and precise injection molding techniques.

| Features | Info |

| Subtypes | Extruded PMMA, Cast PMMA |

| Process | Cutting, Drilling, Engraving, Milling and Routing, Polishing |

| Tolerance | +/- 0.003 in. (0.08mm) with an included resin tolerance that can be greater than but no less than +/- 0.002 in./in. (0.002mm/mm) |

| Applications | Automotive, Medical Devices, Aerospace… |

| Finishing Options | Polishing, hemical Polishing, Coating, Sand Blasting… |

Pros and Cons of PMMA for Injection Molding

PMMA is a popular choice for injection molding because of its versatility and excellent optical properties. However, like any material, it has both advantages and limitations in this context. Our team of experienced engineers can produce components that meet your precise specifications and collaborate with you to optimize PMMA parts, improving the deficiencies to enhance efficiency, cost-effectiveness, and performance.

Superior Transparency

PMMA offers exceptional optical clarity, making it ideal for applications where clear visibility is essential, such as display screens, lenses, and signage, providing high light transmission without compromising strength or durability.

Ease of Molding

PMMA is relatively simple to mold using injection molding techniques, allowing for precise, intricate designs and smooth finishes. It’s particularly suitable for producing parts with complex shapes, reducing post-processing needs and minimizing overall production time.

Lightweight

PMMA is significantly lighter than glass, offering a practical alternative for applications where weight reduction is important without sacrificing the material’s overall strength or transparency, making it ideal for both industrial and consumer products.

Impact Resistance

Although not as tough as polycarbonate, PMMA is far more durable than glass. Its inherent shatter-resistant qualities make it safer and more reliable for applications in areas prone to accidental impacts or where breakage is a concern.

Diverse Finishing Capabilities

PMMA can be molded with a variety of surface finishes, such as high-gloss, matte, or frosted textures, offering flexibility for aesthetic customization. It’s also easy to polish to a crystal-clear finish for high-visibility applications.

Cost-Effectiveness

Compared to other transparent materials like glass or polycarbonate, PMMA is often a more affordable option, especially for large-volume production runs. It offers good performance at a lower cost, making it ideal for budget-conscious projects.

Brittleness

PMMA is prone to cracking or breaking under high stress or impact, making it less suitable for applications requiring high mechanical strength. This brittleness limits its use in more rugged or demanding environments.

Prone to Scratching

PMMA’s surface can easily be scratched, particularly during handling or injection molding, which may affect its aesthetic and optical performance. Careful attention is needed to maintain the material’s appearance and functionality.

Limited Thermal Resistance

PMMA can only withstand moderate heat, with a glass transition temperature around 105°C. This makes it unsuitable for high-temperature applications or environments where thermal stability is a critical factor.

Yellowing Over Time

While PMMA is UV-resistant, it is still susceptible to gradual yellowing or degradation when exposed to prolonged sunlight or harsh environmental conditions. This limits its use in long-term outdoor applications where visual clarity is critical.

Careful Handling Needed

PMMA requires careful handling during both the injection molding process and in post-processing steps to avoid cracking or damaging the material. The brittleness of the material demands extra attention to ensure part integrity and finish quality.

Lower Impact Resistance

Though tougher than glass, PMMA does not offer the same level of impact resistance as some other plastics like polycarbonate. This makes it unsuitable for applications where high-impact strength is essential.

Types of PMMA Injection Molding Materials

PMMA materials, including extruded, cast, impact-modified, UV-resistant, and antistatic grades, offer unique properties for injection molding. Each type varies in optical clarity, impact resistance, and environmental performance, and we utilize different molding techniques to maintain quality and precision for specific applications.

Extruded PMMA (Standard Grade)

Extruded PMMA is produced by forcing molten PMMA through a die to form sheets or rods. It is less expensive than cast PMMA but offers slightly lower optical clarity and surface finish. It’s commonly used for less demanding applications where cost is a primary concern in injection molding.

Tensile Modulus: 3,200–3,500 MPa

Tensile Strain (Yield): 4–8%

Rockwell Hardness (R-scale): M80–M90

Heat Deflection Temperature: 180–190°F

Cast PMMA (High-Quality Grade)

Cast PMMA is known for its superior optical clarity and smooth surface, making it ideal for high-end applications like optical lenses and displays. Injection molding provides precise, high-quality parts, often requiring additional polishing for optimal clarity and surface finish.

Tensile Modulus: 3,500–4,100 MPa

Tensile Strain (Yield): 6–10%

Rockwell Hardness (R-scale): M90–M100

Heat Deflection Temperature: 190–200°F

Impact-Modified PMMA

Impact-modified PMMA enhances impact resistance while maintaining optical clarity. It’s suitable for outdoor signage and automotive parts. Injection molding is effective, but extra care is needed to avoid cracking, especially in high-stress areas, due to its inherent brittleness.

Tensile Modulus: 2,500–3,000 MPa

Tensile Strain (Yield): 5–10%

Rockwell Hardness (R-scale): M80–M90

Heat Deflection Temperature: 180–190°F

UV-Resistant PMMA

UV-resistant PMMA resists yellowing and degradation from prolonged sun exposure, making it ideal for outdoor applications like signage. Injection molding is similar to standard PMMA, but care is needed to avoid overheating, which could compromise its UV protection properties.

Tensile Modulus: 3,200–3,600 MPa

Tensile Strain (Yield): 5–8%

Rockwell Hardness (R-scale): M85–M95

Heat Deflection Temperature: 180–200°F

Antistatic PMMA

Antistatic PMMA prevents static buildup, making it ideal for electronics and cleanroom environments. Injection molding is straightforward, but special care is needed to maintain its static-dissipating properties, ensuring parts are free from contamination during the molding process.

Tensile Modulus: 3,200–3,500 MPa

Tensile Strain (Yield): 6–9%

Rockwell Hardness (R-scale): M90–M100

Heat Deflection Temperature: 190–200°F

Surface Finishing Options for PMMA Injection Molding

At NOBLE, we offer various treatments tailored to your specific aesthetic and functional needs, ensuring consistent quality from prototyping to production through meticulous materials handling, molding, finishing, and CMM testing.

Polishing

Working on metal and hard plastics, our polishing uses highly efficient machinery to get our parts between Ra 0.8~Ra0.1 for a cleaner surface.

Chemical Polishing

Utilizes chemical reagents to selectively dissolve uneven areas on the surface of a sample, thereby eliminating grinding marks and achieving an etching and flattening effect.

Laser Carving

Helpful in brand recognition or parts organization, we use laser carving that applies various printing methods during full-scale production to quickly embed barcodes, lettering and logos on the parts.

Anodizing (for Colored Finishing)

To increase surface hardness and dissipate heat, we use anodizing techniques to enhance the look of parts and blend well for painting and priming.

Powder coating

We apply a thin layer of protective polymer with the corona discharge phenomenon to give our part a lasting finish that protects from impacts and prevents wearing down.

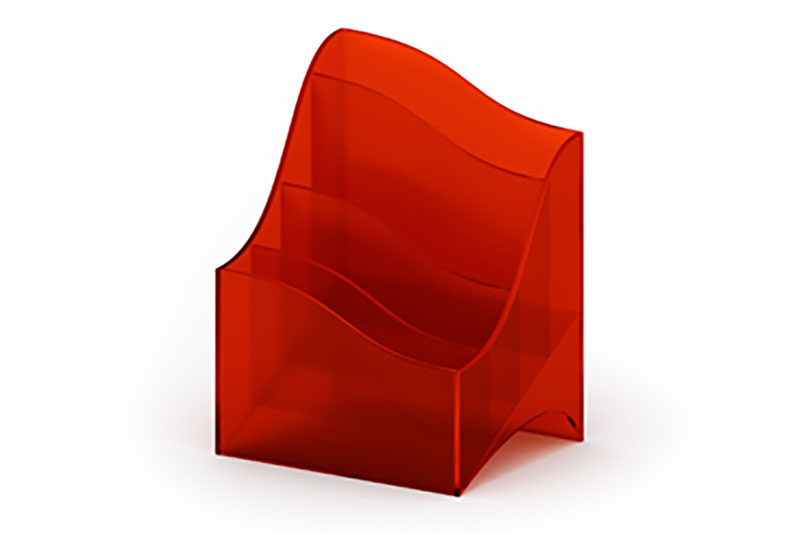

Custom PMMA Injection Molding Parts Display

Explore our over a decade of experience in custom PMMA injection molding, including precision PMMA prototypes and parts crafted to meet the specific needs of our valued customers.

Applications of PMMA Injection Molding

Aluminum CNC machining is widely used in industries such as aerospace, automotive, electronics, and medical devices for producing lightweight, high-precision components like aircraft parts, engine blocks, enclosures, and surgical instruments.

Medical Devices

In the medical field, PMMA is utilized in injection molding for producing components like prosthetics, dental implants, and surgical tools. Its biocompatibility, transparency, and strength make it a preferred material for precise, sterile medical equipment that requires high reliability and clarity.

Automotive Parts

PMMA injection molding is widely used in the automotive industry for components such as headlamp lenses, dashboard covers, and window panels. Its lightweight nature, UV resistance, and optical clarity help enhance both the functional and aesthetic performance of vehicles while reducing weight.

Aerospace Parts

In aerospace manufacturing, injection-molded PMMA is used to create cockpit windows, light covers, and cabin partitions. PMMA's high impact resistance and optical clarity make it an essential material for ensuring safety and visibility in aircraft and spacecraft.

Consumer Electronics

PMMA is used in injection molding to manufacture covers and housings for consumer electronics like smartphones, tablets, and televisions. Its ability to be molded into precise shapes, combined with its durability and aesthetic quality, makes it ideal for high-end electronic products.

Optical Lenses and Displays

PMMA is used in injection molding to produce optical lenses and light guides due to its excellent clarity and light transmission properties. Its ability to be molded into complex shapes enables the creation of intricate optical components for applications like cameras, microscopes, and automotive lighting systems.

Display and Signage Components

Injection-molded PMMA is widely used in the production of illuminated signs, displays, and advertising boards. Its durability, ease of shaping, and ability to transmit light efficiently make it ideal for both indoor and outdoor signage applications, enhancing visibility and aesthetic appeal.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!