Rotational Molding Service

One-Stop Custom Rotational Molding Service

We provide excellent Rotational solutions at competitive prices, from prototyping to production, ensuring you get rotational molded parts with impeccable quality, excellent surface finish, and high stability. We believe that our rotational services will far exceed your expectations.

- 10+ Years of Rotational Molding

- ISO 9001 & ISO13485 Certified Factory

- Advanced Equipment & Cost-Effective Price

- Instant Rotational Molding Quotes

- Provide Free DFM Report within 12 Hours

- Rotational Molding as Fast as 1 Weeks

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Powerful Rotational Molding Processes

It involves heating the plastic material inside the mold while rotating the mold along two perpendicular axes, causing the material to soften and evenly distribute on the inner surface of the mold. It is widely used in playground equipment, kayaks, and custom plastic parts for its cost-effective characteristics.

- 10+ Years of Standard Rotational Molding

- Competitive & Affordable Price

- Fast Turnaround in 7 days

- State-of-the-art Equipment

The mold goes through multiple stages or heating and cooling cycles, with different plastic materials or additives applied at each stage, and the part has different wall thicknesses, materials, or colors. Widely used in toys and complex automotive parts for its ability to support multiple customizations and flexibility.

- 10+ Years of Multi-Stage Rotational Molding

- Competitive & Affordable Price

- Quote Within 24 hours

- State-of-the-art Equipment

It involves mixing a foaming agent with the plastic material during the molding process. The foaming agent causes the material to expand inside the mold, forming a lightweight foam structure. It is widely used in the insulated storage tanks, freezers, and refrigerated container industries due to its light weight and good thermal insulation properties.

- 10+ Years of Gas-Assist Rotational Molding

- Competitive & Affordable Price

- Fast Turnaround in 7 days

- State-of-the-art Equipment

Involves the simultaneous formation of two or more layers of different materials in the same process, each with unique properties. The inner layer can be functional while the outer layer can provide aesthetics or UV resistance. Widely used in multi-layer containers with a higher surface finish due to its cost-effectiveness and corrosion resistance.

- 10+ Years of Co-Extrusion Rotational Molding

- Competitive & Affordable Price

- Fast Turnaround in 7 days

- State-of-the-art Equipment

Rotational blow molding involves using air pressure to form plastic into the desired shape. The mold rotates and air pressure is applied to expand the plastic inside the mold, forming a hollow plastic part. T It is widely used for hollow automotive parts, fuel tanks, and large containers because of its lightweight and strong characteristics.

- 10+ Years of Rotational Blow Molding

- Competitive & Affordable Price

- Tolerances Down to ± 0.0005 mm

- Fast Turnaround in 7 days

During the molding process, a foaming agent is mixed with the plastic material, and the foaming agent causes the material to expand in the mold to form a lightweight foam structure. Due to its good impact resistance and thermal insulation properties, it is widely used in insulating storage tanks and refrigerated containers.

- 10+ Years of Rotational Foam Molding

- Competitive & Affordable Price

- 100% Part Inspection

- Fast Turnaround in 7 days

Our Robust Rotational Molding Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Mold Manufacturing

After mold design approval, we start manufacturing the mold. Then produce samples to test whether they are qualified.

- Free DFM Feedback

- Quote Within 24 hours

- Fast Turnaround in 7 days

- 10+ Years of Mold Making

- State-of-the-art Equipment

- Competitive & Affordable Price

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Rotational Molding Services

NOBLE offers a complete solution, from design and prototyping to production and post-processing. Our team works closely with you to meet your design specifications and quality standards.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Advantages of Rotational Molding

Rotational Molding offers several unique characteristics and advantages over other molding processes. Here are a few reasons why rotational molding is so popular:

Our Rotational Molding Procedures

As a well-known rotational molding manufacturer in China, NOBLE has a comprehensive and organized process that saves you up to 50% of your time and keeps you informed of part production progress.

Request Instant Quote

From the moment we receive your inquiry email, our professional engineers will provide a response within 24 hours to ensure a smooth process.

Design & Mold Design

We collaborate with clients to design custom molds using 3D CAD software, ensuring precise dimensions and uniform wall thickness to meet the part's shape and functional specifications.

Mold Flow Analysis

Predictive modeling software helps us understand how the molten material moves and acts within the mold, which helps us make improvements.

Material Selection

We choose materials like polyethylene, nylon, PVC, or TPE based on performance needs, ensuring the final product has the desired durability, flexibility, and resistance to impact or chemicals.

Heating & Rotation

Plastic powder is placed in the mold, which is then heated and rotated in an oven. The rotation ensures even coating of the mold with molten plastic, forming a uniform layer.

Forming, Cooling & Post-Processing

After heating and rotation, the mold is cooled, solidifying the plastic. Once cooled, the mold is opened, and the part is removed for trimming, surface finishing (such as painting or texturing), and assembly of components, if required.

Sample Inspection&Low Volume Production

Sampling will be delivered for you to review before manufacturing plastic parts to ensure precision and quality. After the trial production phase, we begin batch production, which uses powerful machining to manufacture parts quickly to save time and costs.

Quality Control

Parts undergo strict inspections to ensure dimensional accuracy, uniform wall thickness, and smooth surface finish. We use advanced tools to verify that each part meets the required technical specifications.

Packaging & Delivery

Finished parts are carefully packaged to ensure safe transport. We provide timely delivery, with customized packaging solutions tailored to meet customer needs.

Rotational Molding Tolerances and Standards

With precision rotational molding services and certifications (ISO14001, IATF 16949, ISO 13485), NOBLE is your ideal partner for precision machined prototypes and parts. Our standard CNC machining tolerances are ISO 2768-f for metals and ISO 2768-m for plastics. We can also achieve special tolerances as long as you specify the requirements on your drawing.

Standards | Description |

Maximum Part Size | 47.2×39.4×19.7 in (1200×1000×500 mm) |

Minimum Part Size | 0.039×0.039×0.039 in (1×1×1 mm) |

Part to Part Repeatability | ±0.0039 in (±0.1 mm) |

Mold Cavity Tolerances | ±0.002 in (±0.05 mm) |

Available Mold Types | Primarily steel and aluminum molds |

Machines Available | Single-arm Machines, Dual-arm or Multi-arm Machines (Automatic), Carousel-type Machines, Rotary Molding Machines with Bi-Axial Rotation |

Secondary Operations | Mold texturing, pad printing, laser engraving, threaded inserts and basic assembly. |

Lead Time | 15 business days or less for most orders, 24/7 quotation response |

Class of Rotational Molding Molds

At NOBLE, we design and manufacture precise custom rotational molds using premium materials, ensuring unmatched consistency and repeatability, with fast lead times and affordable prices. Every plastic rotational molded part we produce complies with international standards.

Mold Class | Purpose | Shot Life | Tolerance |

Class 105 | Prototype Testing | Under 500 cycles | 0.0079 in (± 0.02 mm) |

Class 104 | Low-volume Production | Under 100.000 cycles | 0.0079 in (± 0.02 mm) |

Class 103 | Low-volume Production | Under 500.000 cycles | 0.0079 in (± 0.02 mm) |

Class 102 | Medium-volume Production | Under 800.000 cycles | 0.0079 in (± 0.02 mm) |

Class 101 | High-volume Production | Over 1,000,000 cycles | 0.0079 in (± 0.02 mm) |

Materials for Custom Rotational Molding

Our experienced team of engineers and technicians has the expertise to advise you on selecting the most effective materials. Below are some of the common materials we use for our rotational molding services.

Tooling Material

Before the rotational molding process, we select the appropriate material for the mold based on specific needs. The most common materials include:

Material | Advantages |

Aluminum | Lightweight, Cost-Effective for Low to Medium Production, Faster Heating and Cooling, Good for Complex Shapes |

Steel | High Durability, Resistance to Wear, Longer Lifespan |

Stainless Steel | Corrosion Resistance, Durability, Long Lifespan, |

Plastic Materials

In rotational molding, various materials are commonly used, each offering unique properties that make them suitable for different applications.

Polyethylene (PE) | Polypropylene (PP) | Polyvinyl Chloride (PVC) |

Nylon (PA) | Polycarbonate (PC) | ABS |

Additives and Fibers

Standard plastic materials may not meet the requirements of custom rotational molded parts. In such cases, additives and fibers can be incorporated to enhance both aesthetic and functional properties, providing additional features.

UV Stabilizers | Plasticizers | Colorants (Pigments/Dyes) |

Antioxidants | Antimicrobials | Flame Retardants |

Natural Fibers | Glass Fiber | Carbon Fiber |

Surface Finishes for Rotational Molding

NOBLE offers high-quality surface treatment services for rotational molding, providing efficient solutions that enhance both functionality and appearance. Our experienced team will select the most suitable surface treatment for your rotational molding project, ensuring that your parts meet the highest performance and aesthetic standards.

Glossy

A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts.

Semi-glossy

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture.

Matte

C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture.

Textured

D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish.

Quality Inspections for Our Rotational Molding Service

NOBLE’s experienced engineers have the expertise to meet your specific needs. They can handle complex and challenging rotational molding projects and follow a strict quality inspection process to ensure you receive low-cost, high-precision rotational molded parts.

- Free DFM Design Feedback

- T1 samples Inspection Report

- Material Certificate

- Inspection Report Before Shipment

- Trial Mold Parameter & Video Supplying

- Weekly Mold Progress Report

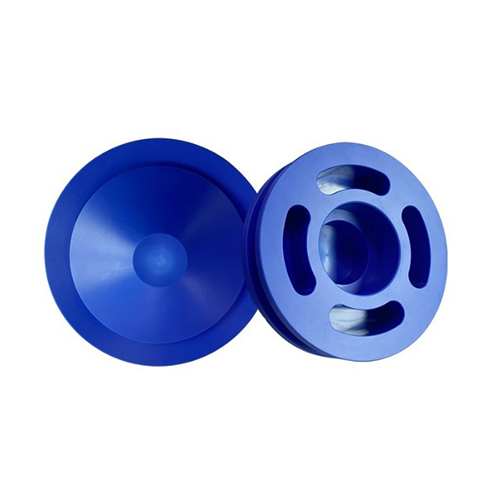

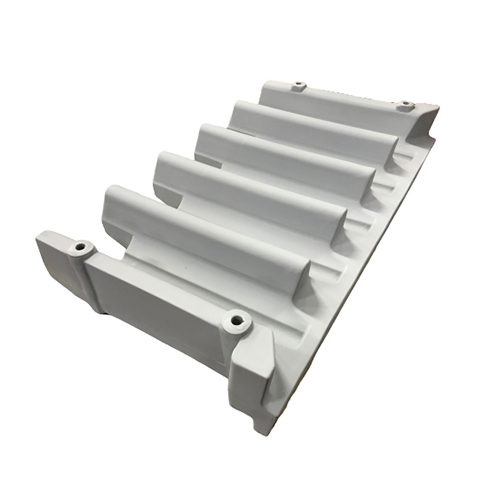

Custom Rotational Molding Parts Display

Check out our over a decade of precision custom rotational molding parts, including precision rotational molded prototypes and parts from our valued customers.

See What Our Customers Say About Us

Customer feedback often has a greater impact than advertising. See what our satisfied customers say about how we met their needs.

Sarah Reynolds

Quality Control Manager

The parts I receive from NOBLE consistently meet my specifications for dimensional accuracy and surface finish. Their team takes great care in ensuring that wall thickness is uniform, and they’ve really helped me streamline my production by improving part consistency.

David Johnson

Product Development Director

NOBLE’s ability to quickly adapt to design changes and deliver parts on tight schedules has been invaluable to my business. I can count on them for both prototypes and low to medium-volume production runs.

Emily Parker

Senior Design Engineer

I was really impressed with how NOBLE handled our complex part designs. They helped us optimize the mold and material selection, and the final product turned out exactly as we envisioned.

John Morris

Operations Manager

From the initial design consultation to final delivery, NOBLE’s team has been responsive and communicative. They were always available to answer questions and guide us through the process.

Helen Davis

Supply Chain Manager

We chose NOBLE for our project because of their cost-effective solutions for low to medium-volume runs. The pricing was competitive, and we didn’t have to worry about expensive tooling costs, which made our production more affordable.

Carlos Gutierrez

Product Manager

The finished products we’ve received from NOBLE have proven to be exceptionally durable and long-lasting. They’ve held up well even in harsh environmental conditions.

Rotational Molding Service for Various Industries

Rotational molding offers a versatile and cost-effective method for manufacturing high-quality plastic parts, making it ideal for a wide range of industries. This process is especially ideal for producing hollow, seamless components with complex shapes and uniform wall thicknesses. Here’s how rotational molding benefits various industries:

Automotive Parts

Rotational molding produces lightweight, durable automotive parts like fuel tanks, bumpers, and interior components. It is cost-effective for low-volume production, supports complex shapes, and provides high strength and UV resistance for extreme conditions.

Medical Devices

This process creates medical equipment cases, trays, and mobility aids. It uses biocompatible materials, provides smooth finishes for hygiene, and offers precision for low-volume runs, making it ideal for high-quality, custom-designed medical products.

Robotics Parts

Rotational molding manufactures lightweight, durable parts for robotics, including enclosures, structural components, and battery covers. It supports complex geometries, enhances mobility, and provides protection from wear and environmental stress, improving robotic performance.

New Energy

In the new energy sector, rotational molding creates weather-resistant parts such as solar panel housings, battery casings, and wind turbine components. It ensures durability, cost-effectiveness, and energy efficiency while withstanding harsh environmental conditions and offering tailored solutions for renewable energy systems.

Automation Industry

Rotational molding produces lightweight, durable components for automation systems, including protective covers, conveyor parts, and cable management systems. It supports customized shapes, reduces weight, and enhances durability, improving machinery efficiency and longevity.

Industrial Products

This process produces durable, customizable products like material handling bins, ducting, and storage containers. It is efficient for low-to-medium production runs and creates large, hollow parts with excellent strength and versatility for industrial applications.

If you are looking for a rapid prototyping manufacturer or CNC machine shop to manufacture your products for low-, medium–, or high-volume production, NOBLE is the ideal choice. Our well-trained and experienced staff manufactures all sizes of parts from drawings on modern CNC machines with the highest precision and machining quality. In addition, we provide professional design considerations for your rotational molding projects.

Want to get the most professional and fast service for your rotational molding project? Upload your CAD file and get a quote now!

Rotational Molding FAQs

Rotational molding is a process used to produce durable, hollow plastic parts. Unlike injection or blow molding, rotational molding involves heating plastic powder inside a mold that is rotated along two perpendicular axes. This melts the powder, evenly coating the mold’s interior and forming a hollow part as it cools.

- Mold Preparation: The mold, typically made of aluminum, steel, or cast iron, is cleaned and prepared for the process.

- 2. Material Loading: A measured amount of plastic powder or pellets is placed inside the mold, with the material selected based on the desired properties of the final product.

- Heating and Rotation: The mold is placed in a rotational oven, where it rotates along axes. As the mold heats, the plastic material melts, coats the mold, and fuses into a smooth, consistent layer.

- Cooling: After melting and coating the mold, it is removed from the oven and cooled in a chamber or with air. The mold continues to rotate to ensure even cooling and solidification of the plastic.

- Post-Processing:In some cases, additional post-processing steps are required, such as trimming, decoration, or assembly.

Rotational molding is ideal for large, hollow, seamless parts with low tooling costs, uniform wall thickness, and small-to-medium production runs.

Injection molding is best for high precision, fine details, smooth finishes, and high-volume production with a wider range of materials.

Rotational molding is a cost-effective process for producing large, hollow, durable parts, but it has certain drawbacks, including material limitations, slower cycle times, and surface finish challenges. These factors should be considered, especially for projects requiring high precision, fine details, or high-volume production.

The cost of rotational molding depends on several factors, including tooling, material costs, part complexity, and order volume. Tooling costs are generally lower than those for injection molding, making rotational molding ideal for low-to-medium production runs. Material selection also affects the cost. The process is cost-effective for production runs starting at a few hundred parts, depending on the size and complexity.

Rotational molding is widely used across industries such as outdoor recreation, automotive, industrial, medical, and consumer goods. It is ideal for producing large, hollow, seamless parts with uniform wall thickness, offering durability, flexibility, and cost-effectiveness for low-to-medium production runs.

After rotational molding, parts can undergo post-processing processes such as painting, texturing, UV coating, or surface smoothing to enhance both appearance and performance. Decorative coatings or logos can also be applied to achieve aesthetic finishes. Surface imperfections, such as air bubbles or inconsistencies, can be smoothed out to meet the desired standards.

At NOBLE, we ensure consistent quality and reliable performance in our rotationally molded parts through advanced technology, strict quality controls, and a skilled workforce at every stage of production. From material selection and mold design to in-process inspections and final testing, we uphold high-quality standards to meet customer requirements.

For the medical and food industries, we comply with regulations, ensuring FDA approval and relevant certifications (e.g., ISO, FDA 21 CFR Part 177). Our production process is thoroughly cleaned, with strict quality controls in place to prevent contamination. Documentation is available to verify compliance with safety standards.

Rotational molding is environmentally friendly, producing minimal waste and utilizing materials efficiently. We use recyclable plastics such as HDPE and PP, and incorporate recycled materials to reduce our environmental footprint. We follow sustainable practices, using energy-efficient equipment and minimizing scrap.