Sheet Metal Waterjet Cutting Service

Our Custom Sheet Metal Waterjet Cutting Services

Custom sheet metal waterjet cutting services, from rapid prototyping to on-demand production. Receive instant quotes and DFM analysis in seconds, and deliver quality sheet metal waterjet parts in days. Upload your CAD files for fast, accurate quotes and integrated production.

- 10+Years of Sheet Metal Waterjet Cutting

- Competitive & Affordable Price

- State-of-the-art Equipment

- Guaranteed Consistent Quality

- Fast Turnaround in 7 days

- 100% Part Inspection

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Powerful Sheet Metal Cutting Processes

At NOBLE, we offer a comprehensive range of precision sheet metal waterjet cutting services using a variety of technologies. Each method is suitable for specific materials, thicknesses, and precision requirements. Based on your needs, we will help you choose the most suitable sheet metal cutting method.

Sheet Metal Laser cutting is a high-precision method that uses a focused laser beam to cut or engrave materials. The laser beam melts, burns, or vaporizes the material, resulting in a clean, precise cut.

- 10+Years of Sheet Metal Laser cutting

- Quality without Compromise

- 20,000+Customer Served

- 100% Inspection

Sheet Metal Plasma cutting uses a high-temperature plasma arc to melt and blow away material, mainly for cutting conductive metals. Sheet metal plasma cutting is highly effective for cutting thicker metals quickly.

- 10+Years of Sheet Metal Plasma cutting

- Fast Turn-around Production

- 99.5% On-time Delivery

- Quote Within 12 hours

Sheet metal waterjet cutting uses a high-pressure stream of water, sometimes with abrasives, to cut through various materials. It’s a non-thermal process, meaning the material isn’t subjected to extreme heat, thus avoiding thermal distortion and changes in material properties.

- 10+Years of Sheet Metal Waterjet Cutting

- Fast Turn-around Production

- 99.5% On-time Delivery

- Quote Within 12 hours

Our Robust Sheet Metal Waterjet Cutting Capabilities

Sheet Metal Prototyping to Production

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Sheet Metal Prototype Machining

At NOBLE, you can get an online sheet metal fabrication quote and free design analysis within hours, and have your sheet metal fabrication prototype completed within days.State-of-the-art Equipment.

- Rapid Prototype Design & Making Services

- Guaranteed Consistent Quality

- 100% Satisfaction Guarantee

- ISO 9001:2015 Certificated

- Competitive Pricing

Rapid Sheet Metal Prototyping

With advanced production equipment and an experienced team of engineers, our sheet metal prototypes can be produced within a few days at a low unit cost, with strict tolerance control and a complete quality inspection process.

- Fast Turn-around Production

- World-class Equipment Such as Hermle

- 50+Member Team

- 100+ Metals & Plastics, 50+ Surface Finishes

- Tolerances Down to ±0.005mm

Batch Sheet Metal Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers large quantities of low-cost, stable-performance sheet metal parts.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Why Choose Us for Custom Sheet Metal Waterjet Cutting Service

From design to prototyping to production, we are ready to turn your ideas into reality with advanced manufacturing solutions tailored to your product. Choosing us for custom sheet metal waterjet cutting means working with a team that values precision, reliability, and innovation. Here are the reasons why we are the ideal choice for your cutting needs:

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Sheet Metal Waterjet Cutting Standards

Check out our over a decade of precision custom sheet metal machined parts, including precision sheet metal waterjet cutting prototypes and sheet metal cutting parts from our valued customers.

Dimension Detail | Tolerance |

Edge to Edge, Single Surface | +/- 0.010″ |

Edge to Hole, Single Surface | +/- 0.010″ |

Hole to Hole, Single Surface | +/- 0.010″ |

Hole Diameter, Single Surface | +/- 0.010″ |

Bend to Edge / Hole, Single Surface | +/- 0.010″ |

Edge to Feature, Multiple Surface | +/- 0.030″ |

Over Formed Part, Multiple Surface | +/- 0.030″ |

Bend Angle | +/- 1 deg |

Materials for Custom Sheet Metal Waterjet Cutting

Our engineers will choose the best cutting method based on your needs and situations. Waterjet cutting is versatile and precise. It can cut through many materials with minimal heat-affected zones. The following are common materials suitable for Sheet metal waterjet cutting:

.jpg 760w, https://www.uprojectspartner.com/wp-content/uploads/2024/11/Aluminum-(4)-300x197.jpg 300w)

Aluminum

Aluminum is a highly ductile metal, making it easy to machining. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

.jpg 800w, https://www.uprojectspartner.com/wp-content/uploads/2024/11/brass-(5)-300x200.jpg 300w, https://www.uprojectspartner.com/wp-content/uploads/2024/11/brass-(5)-768x512.jpg 768w)

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Acrylic (PMMA)

Acrylic is a transparent, impact-resistant material often used in signage and displays. Sheet metal waterjet cutting delivers clean, smooth edges while retaining clarity and preventing chipping, making it ideal for visual applications.

Polycarbonate

Polycarbonate is a durable, high-impact material used in security, automotive, and electronics. Sheet metal waterjet cutting provides precise cuts without heat, preserving its strength and preventing deformation in demanding applications.

ABS

ABS is a versatile thermoplastic used in automotive, construction, and electrical applications. Sheet metal waterjet cutting easily shapes ABS, providing high precision and clean edges without compromising its strength and durability.

Surface Finishes for Sheet Metal Waterjet Cutting

Surface finishing enhances the durability and appearance of your Sheet metal waterjet cutting parts, offering additional protection against corrosion and wear. At NOBLE, we offer various surface finishing options tailored to your needs, ensuring your components achieve the desired look and functionality.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Sand Blasting

Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: ABS, Aluminum, Brass

Color: N/A

Texture: Matte

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

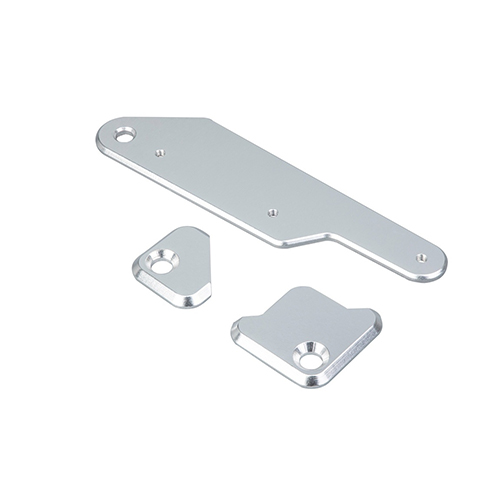

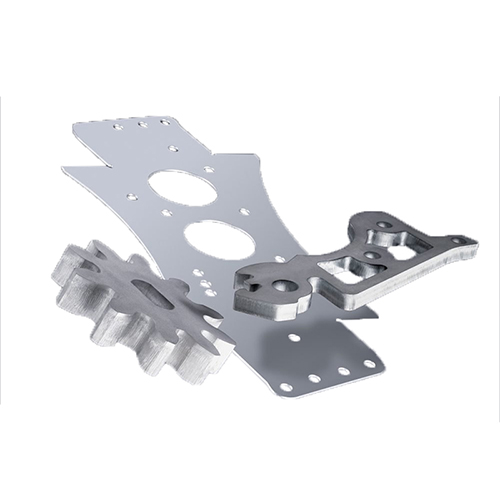

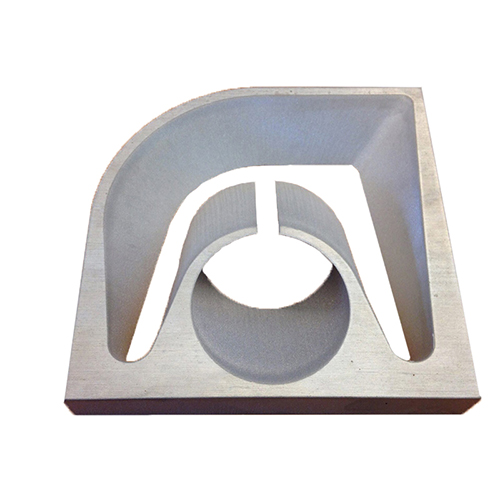

Custom Sheet Metal Waterjet Cutting Parts Display

Check out our over a decade of precision custom sheet metal machined parts, including precision sheet metal waterjet cutting prototypes and sheet metal cutting parts from our valued customers.

See What Our Customers Say About Us

NOBLE has been providing waterjet cutting services for over ten years and has served many overseas customers. Customers’ feedback is more meaningful than the company’s statement—see the objective evaluations from our customers.

Sophie Reynolds

Product Manager

We needed a fast turnaround for custom parts for our prototype line. NOBLE provided exactly what we needed—on time and under budget. Their waterjet cutting process was clean, efficient, and gave us the precision we required for our product development. Highly recommend!

Mark Thompson

Operations Director

NOBLE’s customer service goes above and beyond. From the initial inquiry to the final delivery, their team was incredibly responsive and helpful. They worked with us every step of the way to ensure we got exactly what we needed, and their attention to detail is second to none.

Michael Harris

Senior Manufacturing Engineer

We’ve been using NOBLE for custom metal parts for over a year, and the level of detail and accuracy they achieve with their waterjet cutting is exceptional. The cuts are always smooth and clean, eliminating the need for extra finishing work. It’s one of the reasons why we’ve stayed with them for all our precision parts.

David Clark

Design Lead

NOBLE’s quick turnaround on prototypes helped us get our design to market faster. Their ability to cut complex shapes and materials without the need for expensive tooling allowed us to refine our product quickly. They are now our go-to partner for rapid prototyping.

Emily Davis

Product Development Specialist

NOBLE’s prices are highly competitive, and the quality of their work far exceeds expectations. Their ability to handle complex geometries and maintain tight tolerances at an affordable price has made them a valuable part of our production process.

Our Sheet Metal Waterjet Cutting for Various Applications

As one of the leading precision machining suppliers in China, NOBLE has been providing rapid prototyping and precision quality machining services for more than 10 years. We have exported millions of Sheet metal waterjet-cut parts around the world, helping many OEM customers in a wide range of industries turn their ideas into products and achieve good results.

Aerospace Parts

Sheet metal waterjet cutting is used to create precise aerospace components like turbine blades and engine parts. It allows for complex shapes in materials like titanium and aluminum without heat distortion, essential for meeting strict aerospace tolerances and enabling rapid prototyping.

Automotive Parts

Sheet metal waterjet cutting produces custom automotive parts, such as brake components, exhaust systems, and interior parts. It handles metals and composites, offering precise cuts for complex geometries, making it ideal for automotive manufacturing and prototyping.

Manufacturing and Industrial

Sheet metal waterjet cutting is used to produce custom tooling, dies, and sheet metal parts for industrial manufacturing. Its ability to cut thick metals and precise shapes without heat makes it ideal for machinery and industrial equipment fabrication.

Medical Devices

Sheet metal waterjet cutting is used to create medical device parts, such as surgical tools, implants, and precision components from materials like titanium and stainless steel. Its accuracy and ability to handle complex designs are essential for medical manufacturing.

New Energy

Sheet metal waterjet cutting is used to manufacture turbine blades, reactor parts, and components for renewable energy, such as wind turbines and solar panels. It provides the precision and material handling needed for high-performance energy systems and power generation.

Robotic Parts

Sheet metal waterjet cutting is crucial for producing robotic parts, such as custom frames, end effectors, sensor mounts, and tooling. It offers precision, handles complex geometries, works with diverse materials, and supports rapid prototyping without heat distortion.

If you are looking for a rapid prototyping manufacturer or CNC machine shop to manufacture products for low-, medium–, or high-volume production, NOBLE is the ideal choice. Our well-trained and experienced staff manufactures all sizes of parts according to drawings on modern CNC machines with the highest precision and machining quality. In addition, we provide professional design considerations for your sheet metal fabrication projects.

Want to get the most professional and fast service for your sheet metal fabrication project? Upload your CAD file and get a quote now!

Sheet Metal Waterjet Cutting of FAQs

Waterjet cutting is a precise, versatile method using a high-pressure stream of water, often mixed with abrasives, to cut various materials without altering their properties. It is widely used in requiring precision and material integrity. NOBLE uses high-pressure waterjet cutters to cut titanium sheets to your required sizes, providing near-net-shape products and reducing raw material waste.

The sheet metal waterjet cutting process involves pressurizing water to extreme levels (up to 60,000 PSI) and directing it through a nozzle. For tougher materials, abrasives like garnet are added to the water, creating a more powerful jet that precisely cuts through the material.

Waterjet cutting can be more cost-effective when dealing with thicker, heat-sensitive, or diverse materials, and when edge quality and minimal waste are priorities. Laser cutting may be more economical and practical for high-speed, high-volume production of thin metals and simpler cuts.

To cut thick materials effectively with waterjets, use abrasive waterjets, ensure proper clamping, maintain equipment, optimize speed and abrasive use, employ multiple passes for accuracy, and manage costs through careful setup.

Waterjet cutting excels in precision, versatility, and material compatibility, particularly for thick, heat-sensitive, or intricate parts. While slower and more costly compared to laser and plasma cutting, it’s ideal for a wide range of materials and complex designs without generating heat distortion.

The most challenging materials for waterjet cutting include brittle materials such as glass, composites, soft materials, foams, and thin materials. Adjusting pressure, speed, abrasives, and fixturing is crucial. NOBLE’s engineers have the expertise and experience to solve these problems.

Post-processing for glass and metal improves edge quality, surface finish, and material properties. Glass may require smoothing and polishing, while metal often needs deburring, finishing,and heat treatment for optimal performance.