Compression Molding Services

One-Stop Custom Compression Molding Services

Providing customized compression molding solutions at competitive prices. From prototype design to production, NOBLE has advanced compression molding equipment and an experienced team of engineers to ensure you can obtain high-precision, stable performance, and complex geometry compression molded parts quickly.

- Advanced Equipment & Cost-Effective Price

- 10+ years of Compression Molding Services

- Supports 35+ Surface Surface Finish & 80+ Plastics

- Fast Turn-around Production

- ISO 9001 & ISO13485 Certified Factory

- 24/7 Engineering Support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Powerful Compression Molding Processes

Compression molding is a flexible and versatile manufacturing process where preheated materials are placed in the mold cavity and subjected to high temperature and high pressure to solidify plastics, rubbers, and composite materials into high-strength and durable parts. NOBLE uses advanced compression molding equipment and an experienced team of engineers to ensure that you can receive each high-precision, consistent, and durable compression molded part quickly.

Transfer molding places preheated material into a “tank” or cavity in a separate section of the mold. After the mold is closed, the material is transferred under pressure into the mold cavity, where the hot material is heated and cured, ejecting a precision part with complex geometry.

- 10+ Years of Transfer Compression Molding

- Competitive & Affordable Price

- Quote Within 24 hours

- Guaranteed Consistent Quality

Vacuum compression molding is the application of a vacuum within the mold cavity before or during the compression process. The vacuum helps pull the material more evenly into the mold cavity, reducing the possibility of trapped air or voids. Making it ideal for parts with high appearance or performance requirements.

- 10+ Years of Vacuum Compression Molding

- State-of-the-art Equipment

- Fast Turnaround in 7 days

- 100% Part Inspection

Hydraulic compression molding utilizes a hydraulic press to apply pressure to the material in a mold. The material is heated to the desired temperature, and then the hydraulic press closes the mold to apply consistent, controlled pressure, ensuring that the compression molded part meets precise specifications due to precise control of temperature and pressure. Hydraulic compression molding is particularly useful for large parts that require uniform pressure over a large surface area.

- 10+ Years of Hydraulic Compression Molding

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- 100% Part Inspection

Rubber compression molding is specifically used to mold rubber materials. The process involves placing uncured rubber into a mold cavity and then applying heat and pressure to cure it into its final shape. Rubber compression molding produces parts with excellent mechanical properties and is suitable for producing small to medium batches of durable, flexible, and wear-resistant rubber parts.

- 10+ Years of Rubber Compression Molding

- Competitive & Affordable Price

- Quote Within 24 hours

- 100% Part Inspection

Cold press forming processes thermoplastic materials at a lower temperature to obtain environmentally friendly cold press-formed parts in a short time. Cold press forming usually involves heating only the mold while keeping it at a lower temperature before placing the thermoplastic material into the mold.

- 10+ Years of Cold Compression Molding

- Competitive & Affordable Price

- Fast Turnaround in 7 days

- 100% Part Inspection

Conventional compression molding involves preheating a thermoset or elastomeric plastic body, placing it into a heated mold cavity, closing the mold, and applying pressure to compress the material into the desired shape. The material is held under pressure and heat for a specified period to cure or solidify, then the mold is opened and the part is ejected. Conventional compression molding is ideal for high-volume production because it can create parts quickly and efficiently.

- 10+ Years of Conventional Compression Molding

- Competitive & Affordable Price

- Fast Turnaround in 7 days

- 100% Part Inspection

Our Excellent Thermoforming Mold Services

We provide customized and cost-effective thermoforming mold service solutions at competitive prices. From prototype design to manufacturing, our experienced experts will select the best mold materials for you, manufacture fast, reliable, and efficient compression molding molds, complete the testing and verification of prototype molds, and ensure that you can obtain high-precision thermoforming parts that far exceed your expectations in a short time.

- The overall best tooling option for parts 19”x17” or smaller

- Lowest cost and fastest lead time option for small parts

- Not suitable for ultra high temperature materials

- Very high detail and clean, matte finish

- Permanent tooling

- High accuracy

- Create long-lasting tooling or multiples of a tool at a lower price than printing

- Cheaper than milled aluminum for large parts but very long lead time (we ship a pattern to a foundry)

- Requires a 3D printed or machined master mold

- Permanent tooling

- Highest part consistency from temperature controlled tooling

- The best option for larger tools up to 8+ feet

- Lowest cost and fastest lead time option for large parts

- 30# tooling board for prototyping (50 -100 forms) – matte finish

- 50# tooling board for production (permanent) – matte finish

- 70# tooling board for production (permanent) – polish finish

- Very high accuracy

- Best for clear parts when polished finish is required and forming temperatures are high – polycarbonate and acrylic

- Capable of the finest detail and thinnest mold features – casting requires thicker walls and composite/plastic is not strong enough

- Permanent tooling

- Very high accuracy

- Not necessary or recommended for most projects

Compression Molding Tooling Tolerances and Standards | |

| Description | Detail |

| Size | 98.42in. x 78.74in. x 39.37in. 2500mm x 2000mm x 1000mm |

| Mold Cavities | Single or multi-cavity |

| Mold Life | Unlimited (We will open a new mold if the old one worn out) |

| Mold Storage | Forever |

| Mold Material | P20 Steel |

| General Tolerance | Normally +/- 0.008in.(0.2mm) |

*Note: Tooling surface finish is only important for clear materials or glossy finishes on the mold side. It is not critical for most opaque materials and male/male molds. For clear plastics, a matte finish will leave a frosted/diffuse texture on the mold side, which may or may not be desirable.

Our Robust Compression Molding Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom compression molding solution. From prototyping to manufacturing, turning your ideas into reality through vast manufacturing resources,appropriate technology, streamlined processes, expert guidance, and perfect quality inspection processes.

Compression Molding Prototyping

NOBLE engineers use advanced prototyping molds to easily get design feedback and verification. Use excellent compression molding prototypes to create small batches of plastic molded parts. NOBLE focuses on making prototype molds within a few days to ensure that you can conduct functional testing and verify market interest. Help you reduce project risks before the full production of parts and provide you with strong project support.

- Free DFM Feedback

- Quote Within 24 hours

- Fast Turnaround in 7 days

- 10+ Years of Mold Making

- State-of-the-art Equipment

- Competitive & Affordable Price

Production Tooling

We manufacture high-quality production tooling for high-volume plastic part production. Our production tools are made from high-strength, durable tool steel materials suitable for producing hundreds of thousands of parts. We can vary materials and construction methods according to your unique requirements.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Compression Molding Tooling

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Low-Volume Compression Molding

NOBLE meets low to medium-volume production needs with tight tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision compression molded parts.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Compression Molding

- Fast Turn-Around Production

- 100% Part Inspection

Why Choose Us for Custom Compression Molding Service

We have more than 100 advanced compression molding equipment and an experienced team of engineers. Our experienced project managers provide in-depth manufacturing analysis and prototype design services to help you optimize structural design, select the right process, reduce costs, shorten project cycles, and ensure that you receive compression molded parts that exceed industry standards in a short period.

Work with Us in 4 Simple Steps Only

With many years of experience in compression molding manufacturing, NOBLE provides the best solutions for all rapid prototyping and low-volume manufacturing needs. We simplify the innovation cycle into four simple but effective steps.

Compression Molding Tolerances and Standards

With our high-precision compression molding services, NOBLE is your ideal partner for precision-machined prototypes and parts. Our standard CNC machining tolerances for metals are ISO 2768-f and for plastics are ISO 2768-m. We can also achieve special tolerances as long as you specify the requirements in your drawing.

Description | Metric | Inch |

Length | 3000 | 118 |

Width | 2500 | 98.4 |

Height | 2000 | 78.7 |

Hole Diameters | ±0.005 mm | ±0.002 inch |

Linear Dimension | ±0.01 mm | ±0.004 inch |

DRILLED HOLE DIAMETERS | +/-0.005” | Holes Equal or Lesser than 1” |

SLOTS | +/-0.010” | Slot Equal to or Lesser than 1” Any Direction |

FORMED MEASUREMENTS | +/-0.015″ | Tolerance and size increase proportionally |

Materials for Compression Molding

As a professional on-demand manufacturer, NOBLE offers a variety of compression molding materials to meet customers’ unique requirements. In compression molding, thermosetting plastics, rubbers, and composites are widely used because they can undergo a curing process and achieve a stable, rigid form. The following are some materials that can be used for compression molding. We also provide material modification services. Our professional material engineers will adjust the raw material formula to meet the unique usage conditions and special needs of customers.

Elastomer and Rubber

Elastomers and rubbers are common materials for compression molding processes. The following are various compression molding materials that NOBLE offers to meet the unique requirements of our customers.

- NR

- SBR

- CR

- VMQ

- FFKM

- NBR

- IR

- FKM

- EPDM

Plastic Materials

Thermoset plastic materials can be used in compression molding processes due to their excellent heat resistance and dimensional stability. NOBLE offers a variety of thermoset plastic compression molding materials to meet the unique requirements of our customers.

- UHMWPE

- PTFE

Thermoplatic-Rubber

Thermoplastic elastomers (TPE) have excellent elasticity, flexibility, and resilience and can be used in compression molding processes. NOBLE offers a variety of thermoplastic elastomer molding materials to meet the unique requirements of our customers. Please view NOBLE’s thermoplastic elastomer (TPE) materials.

- TPE

- TPV

- TPU

- TPR

Surface Finishes for Compression Molding Services

NOBLE provides excellent compression molding surface treatment services, and efficient surface treatments improve the functionality and aesthetics of parts. Our experienced experts will select the right surface treatment for your compression molding project, ensuring that your compression molded parts meet the highest standards of performance and aesthetics.

Glossy

The Class A surface is made by the diamond polishing process, which is smooth and highly reflective, giving the product a beautiful and shiny appearance, and can produce a shiny and smooth surface on compression molded parts.

Semi-glossy

The Class B finish has a low reflective sheen, a smooth and slightly glossy appearance, and uses coarse sandpaper to produce parts with a slightly rougher surface than the Class A finish. Custom compression molded parts with a Class B finish have a matte surface texture.

Matte

C-grade polishing uses grit to create a rough, non-reflective, dull appearance. Often used for parts where glare or light reflection is undesirable. Compression-molded parts that have been C-grade polished have a matte surface texture.

Textured

D-Class D finish uses grit and dry glass beads or oxides to produce a very rough textured surface, which can provide a better grip or a unique look to compression molded parts. Depending on the type of material used, compression molded parts can have a satin or dull finish.

Quality Inspections for Our Compression Molding Service

NOBLE’s experienced engineers have the expertise and experience to meet your specific needs, can undertake complex and challenging compression molding projects, and strictly implement our strict quality inspection process to ensure that you get low-cost, high-precision compression molded parts.

- Material Certificate

- Free DFM Design Feedback

- Weekly Mold Progress Report

- Trial Mold Parameter & Video Supplying

- T1 samples Inspection Report

- Inspection Report Before Shipment

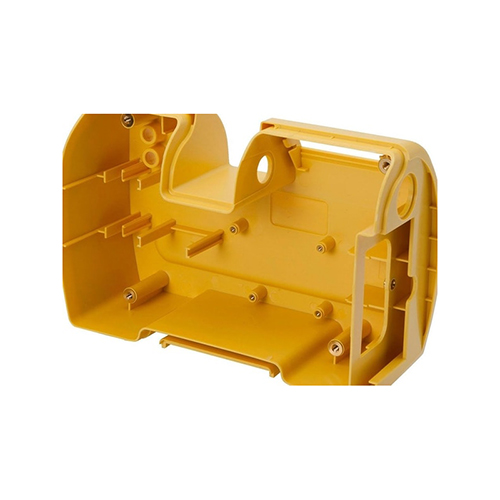

Custom Compression Molding Parts Display

From prototyping to compression molding for customers at competitive prices, which showcases some of our finished high-quality consistent-performance compression molding parts, trust us to create your compression molding project according to your exacting specifications.

See What Our Customers Say About Us

Check out our over ten years of custom compression molding services, including our valued customers’ precision compression molding prototypes and parts.

Martin K

Product Designer

We had a pleasant communication with the NOBLE staff. Their project engineers were very experienced and helped me optimize the design, select the appropriate process, and reduce costs, and the quality of the manufactured parts far exceeded my expectations.

Zackery Evans

Project Engineer

I have worked with the NOBLE team in the past and they always produce quality compression molded parts perfectly. Their responsiveness and ability to quote within a day make them my first choice. They are also very communicative and are able to get to the bottom of my compression molded design needs or ask questions to ensure they can do the job perfectly.

Thomas

Project Engineer

I had a very pleasant experience working with NOBLE. Communication was very accurate and prompt from the beginning. Details in the design that might cause production difficulties were pointed out promptly and a perfect compression molding solution was proposed, and the price of the prototype design was very competitive. The quality control of the final product was also excellent. I will use them again.

Devin

Vice President

NOBLE continues to exceed my expectations. I have been with them for over 3 years now and every interaction with them reminds me how glad I am to have found them. I have used many overseas machine shops over the years and NOBLE is so much better than all the others that I can’t even really compare them. Communication is very smooth, they always deliver on time, and the quality is exceptional. The prices are a little higher than what I have paid elsewhere, but well worth it in my opinion. I have complete confidence that NOBLE will deliver on their promises and it is such a breeze to work with them.

Compression Molding Service for Various Industries

Compression molding is a widely used manufacturing process that involves placing a thermoplastic polymer material in an open, heated mold cavity. The material is then compressed under pressure to take on the shape of the mold. The compression molding industry is constantly innovating, driven by progress and the growing demand for sustainable and lightweight solutions across industries. The following are the main applications:

Automotive Industry

The automotive industry uses compression molding extensively to create lightweight and durable parts. CNC machining manufacturers use compression molding to create automotive exterior parts such as bumpers, fenders, and body panels. Of course, it can also make car dashboards and engine covers. In addition, composite materials such as sheet molding compounds and bulk molding compounds can improve the strength-to-weight ratio.

Aerospace Industry

In the aerospace industry, weight reduction is crucial, and compression molding has become the best choice for manufacturing aircraft parts. CNC processing manufacturers usually use compression molding to manufacture high-performance composite parts such as aircraft wing spars, fuselage panels, and fairings.

Medical Industry

Compression molding is widely used in the medical field due to its sterility and biocompatibility. CNC machining manufacturers often use it to manufacture medical parts or prototypes with complex geometries, corrosion resistance, and high precision.

Consumer Goods

Compression molding is widely used in the fields of furniture and sports equipment due to its high strength and corrosion resistance. CNC machining manufacturers often use it to manufacture household parts and sports equipment with excellent surface finish and high dimensional accuracy. Compression molding is widely used to manufacture durable and beautiful products such as kitchenware, protective equipment, and toys.

New Energy

Ideal for using compression molding to manufacture parts for renewable energy systems. CNC machining manufacturers often use it to manufacture large-scale new energy parts with complex geometries, corrosion resistance, and high precision, such as wind turbine blades, nacelles, and housings for solar energy systems, etc.

Robotics Industry

Compression molding plays a key role in the robotics industry and is the best choice for manufacturing high-performance and structural parts for robots. Compression molding is able to produce lightweight and high-strength robotic parts with complex geometries, precision, and cost-effectiveness. From structural frames to end effectors and electronic housings, the compression molding process supports the design and functionality of robots in a variety of applications. With advances in material science and molding technology, the future of robotic compression molding will continue to grow and innovate.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Compression Molding FAQs

Compression molding is a thermoplastic or thermoset material processing process, which is often used to manufacture high-strength, high-durability parts. The process is performed by placing plastic or composite materials into the opening of the mold, softening the material under high temperature and pressure conditions, and forming it into the shape of the mold.

Compression molding is widely used in the automotive, aviation, electronics, construction, and household goods fields, and is often used to manufacture parts such as car bumpers, electrical housings, industrial components, and composite panels. Its advantages include the ability to produce parts with complex shapes, high efficiency, and low waste, but it may also have a higher initial cost due to higher equipment requirements.

Compression molding has several advantages that make it a top choice for industries such as automotive, electrical, aerospace, and construction. It is used to manufacture components such as gaskets, bumpers, housing units, and composite panels.

- Cost-effectiveness of large parts: Compared with other molding processes, compression molding is well suited to produce large and heavy parts at a relatively low cost, especially in medium and large batches.

- Material versatility: It is suitable for a variety of materials, including thermosets, thermoplastics, and composites, for different applications.

- High strength and durability: The parts produced by this process have excellent mechanical properties, including high strength and durability, suitable for demanding applications such as automotive and aerospace components.

- Complex shapes and large sizes: Compression molding can handle complex designs and large parts, with flexibility in part geometry and size.

- Minimal material waste: Unlike some other molding processes, compression molding produces less material waste, making it more environmentally friendly and cost-effective.

- Good surface finish: The parts produced generally have a smooth surface finish, reducing the need for additional finishing operations.

- High production efficiency: The process is relatively fast and efficient and can achieve high output in a production environment.

- Inserts can be integrated: Compression molding allows metal or other inserts to be integrated during the molding process, thereby expanding the functionality of complex parts.

Compression molding is a manufacturing process that uses heat and pressure to shape a material into a desired shape. Compression molding involves preheating a fixed amount of molding material and compressing it into the desired shape using two heated molds. A step-by-step description of the compression molding process is as follows:

- Material preparation: The raw materials, usually thermoset resins, thermoplastics, or composites, are pre-weighed and placed in the mold. The materials can be in various forms, such as powders, granules, flakes, or preforms.

- Heating the mold: The mold is preheated to the required processing temperature. This ensures that the material can flow properly and form the shape of the mold.

- Loading the material: The prepared material is placed in the open mold cavity. The placement ensures that the pressure is evenly distributed when applied.

- Compression and molding: The mold is closed and high pressure is applied to compress the material. The heat and pressure make the material flow and fill the mold cavity, forming the shape. For thermoset materials, this step also triggers the curing process, which hardens the material and permanently fixes it.

- Cooling and curing: The material is under heat and pressure for a specified time to ensure that it is fully cured (for thermoset materials) or cooled and solidified (for thermoplastics). The time required depends on the material and the complexity of the part.

- Demolding: After the material solidifies, the mold opens and the finished part is ejected. Care is taken during the removal process to avoid damaging the component.

- Trimming and finishing: Excess material, called burrs, is trimmed away. If required, other finishing operations such as painting, coating, or machining may be applied.

Several factors can affect the quality and efficiency of the compression molding process. Careful consideration and control of these factors can help improve production efficiency, reduce defects, and produce high-quality compression molded parts. The following are key factors:

- Material Selection:

Material Type: Thermosets, thermoplastics, and composites behave differently during the molding process, affecting flow, cure, and strength. Viscosity, cure time, and thermal expansion can affect the molding process and final product quality. - Mold Design:

Shape and Complexity: The geometry of the mold can affect the material’s ability to flow and fill the cavity.

Mold Material: Choose a durable material like steel or aluminum for high strength and heat resistance.

Ventilation: Proper ventilation ensures that trapped gases can escape, preventing defects such as bubbles. - Pressure Application:

Pressure Level: The pressure applied must be sufficient to ensure that the material flows evenly and fills the mold cavity.

Uniformity: Inconsistent pressure can result in uneven thickness or incomplete fill. - Temperature Control:

Heating: The mold must reach and maintain the correct temperature to allow the material to flow and cure or solidify effectively.

Cooling: Controlled cooling prevents warping or shrinkage and ensures that the material solidifies properly. - Material Loading:

Material Amount: Too much material can cause flashing, while too little material can result in an incomplete part.

Placing: Evenly placing the material ensures uniform flow and reduces defects. - Cure Time:

Dwell Time: The duration of heat and pressure applied must match the material’s curing requirements.

Under- or Over-Cure: Improper curing can weaken the part or cause defects. - Mold Surface Finish:

Smooth, clean mold surfaces reduce the need for post-processing and ensure surface quality of the part. - Mold Alignment:

Proper alignment of the mold halves is critical to avoid parting line misalignment or dimensional inaccuracies. - Environmental Factors:

Humidity: Moisture can affect material properties, especially hygroscopic materials such as composites.

Ambient Temperature: Variations can affect the thermal stability of the process. - Operator Skill and Process Control:

Skilled operators and precise control systems ensure consistency and reduce errors in material handling, pressure application, and temperature management.

In short, compression molding cycle times typically range from 30 seconds to 5 minutes, depending on factors such as material type, part size and complexity, curing or cooling requirements, and the efficiency of the mold and equipment.

Injection molding is better suited for high-volume production, while compression molding is better suited for pliable and flexible materials. For low to medium production volumes and simple parts, compression molding is cheaper because of lower tooling and equipment costs. However, for large-scale production of complex and precision parts, injection molding is more cost-effective because higher tooling costs are offset by economies of scale and faster cycle times.

Thermoforming primarily uses thermoplastic materials because they soften when heated and can be reshaped. These materials are selected based on properties such as durability, aesthetics, flexibility, clarity, and cost-effectiveness for a particular application. Common types include:

- Acrylic (PMMA): Known for its clarity and rigidity.

- Polyethylene (PE): Durable and flexible.

- Polypropylene (PP): Lightweight and resistant to chemicals.

- Polystyrene (PS): Cost-effective and used for disposable items.

- Polyvinyl chloride (PVC): Versatile and strong, available in rigid and flexible forms.

- Polycarbonate (PC): Impact-resistant and transparent.

- Acrylonitrile butadiene styrene (ABS): Durable and suitable for complex shapes.

NOBLE only lists a few materials. If you have any questions about materials, Kevin is happy to help you.

At NOBLE, we take quality very seriously. We are ISO 9001 certified and ISO13485 certified.

We have trained molding and milling technicians to check the product processing process and have a capable engineering team to set standards.

The strict quality inspection process is as follows:

- Material inspection: Verify the quality and specifications of the incoming thermoplastic material.

- Tool and mold verification: Ensure that the mold dimensions are accurate and suitable for the design.

- In-process monitoring: Check key parameters such as temperature, pressure, and cycle time during the molding process.

- Dimensional inspection: Measure the molded part to ensure it meets the design tolerance.

- Visual inspection: Check for defects such as warpage, cracks, bubbles, or uneven thickness.

- Functional testing: Evaluate part performance according to specific application standards.

- Documentation and traceability: Record inspection and test results for accountability.

This structured approach ensures consistency, precision, and reliability of thermoformed parts.

Any quality control process relies on pre-definition, which is why we need drawings from our team or customers. Your parts will be checked against these drawings to ensure compliance.

In the rare case that a product does pass quality control and the customer receives the product but refuses these non-conforming (NCR) parts, we will take responsibility and issue an RMA to rework or replace the product at no charge to the customer.

We don’t have a minimum order quantity, but I wouldn’t recommend it because we buy plastic by the sheet, and whether you use it all or not, I’ll have to buy at least one full sheet, which will usually cost you thousands of dollars for compression molding material, and hundreds of dollars for molding and CNC trimming setup material. Then the setup costs are spread out over the part. So if you’re only ordering a few parts, each part could cost over $100, and then add in your tooling costs, which can make tooling expensive.