Magnesium

Custom Magnesium Machining Service

NOBLE provides tailor-made magnesium CNC machining solutions at competitive prices, from prototype design to production, ensuring strict adherence to your specifications, allowing you to quickly obtain stable performance, high-precision magnesium CNC machined parts or prototypes.

- Advanced Equipment & Cost-Effective Price

- 10+ years of Magnesium Machining Services

- ISO 9001 & ISO13485 Certified Factory

- Competitive Price 30% Cost Save

- Guaranteed Consistent Quality

- 99.5% On-time Delivery

Our Magnesium Machining Capabilities

NOBLE’s advanced CNC machining expertise for magnesium alloys addresses the unique challenges of these materials. From prototyping to mass production, we manufacture complex, high-aesthetic products. We apply the most suitable solution to address magnesium’s heat sensitivity and material characteristics, delivering high-quality, reliable components for various industries.

| Price | $$$ |

| Lead Time | <7 days |

| Wall Thickness | 0.75 mm |

| Tolerances | ±0.005″ (±0.125mm) |

| Max Part Size | 200 cm x 80 cm x 100 cm |

| Available Magnesium at NOBLE | AZ31B, AZ61A, WE43, AM60B, ZK60A |

Characteristics of Magnesium Machining Materials

Magnesium alloys are lightweight with a high strength-to-weight ratio, offering excellent machinability. However, they are heat-sensitive and prone to ignition during CNC machining, requiring precise control over cutting speed, tooling, and cooling to ensure high-quality, safe, and efficient production.

| Features | Info |

| Subtypes | AZ31B, AZ61A, WE43, AM60B, ZK60A… |

| Process | CNC Milling, Turning, Drilling, Grinding, Die Casting, Laser Cutting |

| Tolerance | ±0.005″ (±0.125mm) |

| Applications | Aerospace, Automotive, Electronics, Military and Defense, Medical Devices, Sporting Goods |

| Finishing Options | Anodizing, Powder Coating, Painting, Surface Grinding, Brushing, Electroplating |

Pros and Cons of Magnesium for CNC Machining

Magnesium alloys are increasingly popular in CNC machining due to their lightweight, high strength-to-weight ratio, and machinability. While they offer significant benefits in industries like aerospace and automotive, their unique properties also present challenges, such as heat sensitivity, tool wear, and corrosion, requiring specialized CNC machining techniques for optimal results.

Lightweight

Magnesium alloys are the lightest of all structural metals, offering a significant reduction in weight without sacrificing strength. This property is particularly valuable in industries like aerospace, automotive, and electronics, where reducing weight can improve performance, fuel efficiency, and overall product design, making magnesium a preferred choice for lightweight components.

Corrosion Resistance

Magnesium alloys can exhibit reasonable resistance to corrosion when treated with surface coatings or when alloyed with other materials like aluminum or zinc.

Recyclability

Magnesium is fully recyclable, making it an environmentally friendly material choice. It is increasingly being used in sustainable CNC machining processes.

Versatility

Magnesium can be alloyed with various elements (like aluminum, zinc, and manganese) to enhance specific properties, such as strength, corrosion resistance, and workability, making it suitable for various applications.

High Strength-to-Weight Ratio

Magnesium alloys offer an excellent strength-to-weight ratio, making CNC-machined magnesium for applications that require both structural integrity and low mass. This is crucial in high-performance sectors, such as aerospace and automotive, where components need to withstand stress while minimizing overall weight to optimize fuel efficiency, speed, and load-bearing capacity.

Good Machinability

Magnesium alloys are relatively easy to CNC machine compared to other metals, allowing for efficient production of intricate and complex parts with tight tolerances. This is due to their low density and relatively soft nature, making them ideal for high-precision CNC machining. However, careful control of cutting parameters is essential to avoid overheating or tool wear.

Thermal Conductivity

Magnesium has excellent thermal conductivity, which helps dissipate heat effectively during CNC machining and in final applications. This makes magnesium alloys particularly beneficial for components like engine parts, electronics enclosures, and heat exchangers, where heat dissipation is essential to prevent overheating and ensure efficient performance in demanding environments.

Heat Sensitivity

Magnesium alloys have a low ignition point, which makes them highly sensitive to heat during CNC machining. If machining speeds, tool wear, or cooling methods are not controlled properly, magnesium can catch fire. This requires the use of specialized cooling fluids, lower cutting speeds, and enhanced safety measures to mitigate the risk of combustion during production.

High Machining Costs

Magnesium is relatively more expensive than aluminum or steel due to extraction and alloying processes. This can make the overall production costs higher, especially for large-scale manufacturing.

Lower Hardness

While magnesium is lightweight and strong, it can also be brittle compared to other metals, especially in its pure form. This makes it more prone to cracking or breaking under certain conditions, which may require careful handling and design considerations.

Limited Availability

While magnesium is abundant in the Earth’s crust, it is less readily available for industrial use compared to other metals like aluminum or steel. This can lead to supply chain constraints, especially for high-demand applications.

Surface Treatment Requirement High

Magnesium alloys are highly susceptible to corrosion, especially in harsh environments. To improve durability and corrosion resistance, surface treatments such as anodizing, coating, or painting are often necessary, adding extra steps to the manufacturing process.

Tool Wear

Despite their machinability, magnesium alloys are relatively soft and can generate fine, abrasive chips during machining. This can result in accelerated tool wear, reducing tool life and increasing maintenance costs. To manage this, CNC machines must use high-quality cutting tools, and operators should adjust machining parameters to balance productivity and tool longevity.

Machining Challenges

Although magnesium has good machinability, it can pose difficulties related to chip control and handling due to the flammability risk. The material also tends to produce fine, sharp chips during CNC machining, which can be hazardous and difficult to manage.

Alloy Sensitivity

The properties of magnesium alloys can vary widely based on the specific alloy composition. This variability can sometimes complicate CNC machining processes, requiring different strategies and considerations based on the particular alloy being used.

Corrosion

Magnesium is highly prone to corrosion, especially when exposed to moisture or harsh chemicals. This makes it less suitable for use in certain environments unless it is treated or coated. To extend the lifespan of magnesium components, surface treatments such as anodizing, coating, or plating are often required. In this process, engineers need to have more experience and ability in CNC machining.

Safety Concerns

Magnesium dust and chips are highly flammable and can pose significant safety risks if not handled properly during CNC machining. Special care must be taken to manage and remove chips efficiently, and appropriate fire suppression systems must be in place. Additionally, proper ventilation and protective equipment are essential to ensure the safety of operators and the facility.

Types of Magnesium Machining Materials

Magnesium is heat sensitive and requires precision CNC machining to obtain complex shapes and tight tolerances for magnesium CNC machined parts or prototypes. NOBLE’s state-of-the-art, regularly updated machines ensure you get high-precision magnesium machined parts that meet your most stringent accuracy and performance standards.

AZ31B

AZ31B is a versatile, lightweight alloy featuring excellent formability and moderate strength. It has good corrosion resistance and is commonly used in automobiles, aerospace, and electronic components. Its machinability is excellent, although care must be taken because it is prone to heat during CNC machining.

Yield Strength(MPa): ≈170–230 MPa

Elongation at Break(%): 15–20%

Hardness(Brinell): 50–70 HB

Density(g/cm³): ≈1.77 g/cm³

Maximum Temp: 300℉

AZ61A

AZ61A offers a higher strength than AZ31B due to its increased aluminum content, making it suitable for structural applications. It maintains good machinability and corrosion resistance, especially in moderately corrosive environments, but its high strength can lead to an increase in tool wear during CNC machining.

Yield Strength(MPa): ≈220-280MPa

Elongation at Break(%): 10-15%

Hardness(Brinell): 60-80HB

Density(g/cm³): ≈1.8 g/cm³

Maximum Temp: 350℉

WE43

WE43 is designed for high-performance applications, incorporating rare earth elements for improved strength and creep resistance at elevated temperatures. It’s particularly used in the aerospace and military industries. CNC machining WE43 requires careful control of speed and tool selection because it has stronger toughness than other magnesium alloys.

Yield Strength(MPa): ≈280-310MPa

Elongation at Break(%): 6-8%

Hardness(Brinell): 90-100HB

Density(g/cm³): ≈1.81g/cm³

Maximum Temp: 500℉

AM60B

AM60B is favored for its high impact strength and good fatigue resistance, making it ideal for automotive and die-casting applications. Its relatively high aluminum content improves its strength, but because of its low melting point and tendency to generate heat during cutting, this alloy is a challenge for CNC machining.

Yield Strength(MPa): ≈130-180MPa

Elongation at Break(%): 5-10%

Hardness(Brinell): 50-60 HB

Density(g/cm³): ≈1.8g/cm³

Maximum Temp: 350℉

ZK60A

ZK60A combines magnesium with zirconium, which enhances its creep resistance and overall strength, especially at elevated temperatures. Although it provides good CNC-machinability and welding characteristics, it is usually used in aerospace applications where high strength-to-weight ratios are crucial.

Yield Strength(MPa): ≈290-340MPa

Elongation at Break(%): 5-8%

Hardness(Brinell): 80-100 HB

Density(g/cm³): ≈1.81g/cm³

Maximum Temp: 500℉

Surface Finishing Options for Magnesium Machining

Surface treatments enhance magnesium CNC machining by improving appearance, corrosion resistance, and durability. With over 150 CNC machining machines and over 100 materials and surface treatments, we ensure fast turnaround and high-quality prototypes and production parts. The following are common surface treatment options for magnesium alloys:

As Machined

Coming out of the machine after machining, our parts are cleaned of any sharp edges and burrs while retaining marks. Without any added material, the part had a surface roughness of 3.2 μm (126 μin).

Anodizing

To increase surface hardness and dissipate heat, we use anodizing techniques to enhance the look of parts and blend well for painting and priming.

Powder Coating

We apply a thin layer of protective polymer with the corona discharge phenomenon to give our part a lasting finish that protects from impacts and prevents wearing down.

Electroplating

Electroplating reduces metal cations in the electrolyte solution, producing a metallic coating on a metal surface. This process can be used for purposes of corrosion and wear resistance, as well as for decorative purposes.

Laser Carving

Helpful in brand recognition or parts organization, we use laser carving that applies various printing methods during full-scale production to quickly embed barcodes, lettering and logos on the parts.

Brushing

Our brushing technique uses abrasive belts over the material to create diverse patterns that match the parts’ structure and color.

Sand Blasting

Band blasting cleans the surface of any impurities and peels coating through the propelling of blast media streams over the parts.

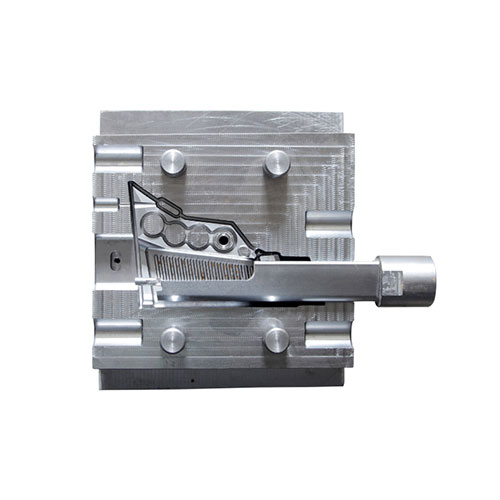

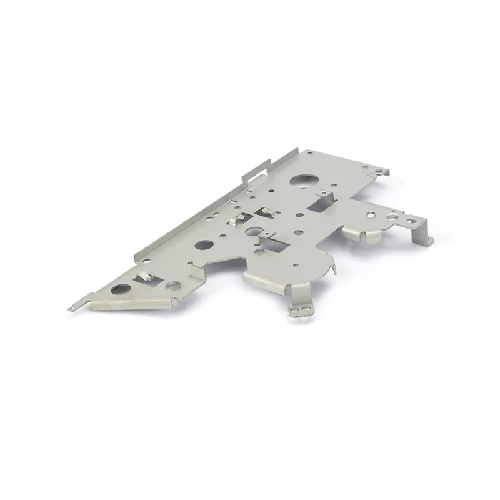

Custom Magnesium Machining Parts Display

Check out our over a decade of custom Magnesium CNC machining parts, including precision Magnesium prototypes and parts from our valued customers.

Applications of Magnesium CNC Machining

Magnesium CNC machining offers versatile applications across industries, leveraging magnesium’s lightness, strength, and machinability. Our advanced capabilities, cutting-edge equipment, and expert team ensure precision-crafted components that meet the highest industry standards.Below are some key applications of magnesium CNC machining, where we combine innovation and expertise to provide exceptional solutions:

Aerospace Parts

Magnesium alloys are favored in aerospace for their light weight and strength. CNC machining allows for precise fabrication of parts like engine components and frames, reducing aircraft weight to improve fuel efficiency and performance. Magnesium’s strength and machinability also make it ideal for critical helicopter parts, enhancing both maneuverability and safety.

Automotive Parts

Magnesium alloys play a key role in automotive manufacturing by reducing weight while maintaining strength. CNC machining helps create components like engine blocks and wheels with high precision, improving fuel efficiency and performance. This is particularly crucial for electric and performance vehicles, where every weight reduction enhances speed and energy efficiency.

Electronics and Consumer Goods

Magnesium alloys are widely used in electronics for their lightweight, durable properties. CNC machining enables the creation of sleek, functional casings for devices like smartphones, laptops, and cameras. Magnesium’s premium feel makes it a top choice for high-end electronics. Its versatility also extends to tools and medical equipment, where precision is key.

Sporting Goods and Equipment

Magnesium is commonly used in high-performance sporting goods like golf clubs, tennis rackets, and bike frames. Its lightweight improves maneuverability, and CNC machining ensures precise, durable designs. Magnesium’s ability to be easily shaped makes it perfect for creating high-quality, high-performance sports equipment that optimizes both strength and agility.

Medical Devices

In the medical field, magnesium alloys are valued for their lightweight and biocompatibility. CNC-machined surgical instruments reduce fatigue for medical professionals, improving precision. Magnesium implants, such as bone screws, naturally degrade in the body, eliminating the need for removal. These properties enhance both the functionality and recovery process for patients.

New Energy

Magnesium alloys are increasingly used in the energy sector for their strength-to-weight ratio. CNC machining helps reduce the weight of structural components in wind turbines and electric vehicles, improving energy efficiency. Additionally, magnesium is being researched for use in next-gen batteries, offering sustainable, cost-effective solutions for energy storage and renewable energy systems.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!