Thermoforming Services

Our Custom Thermoforming Services

Upload your CAD files and get an instant quote online. NOBLE is a thermoforming manufacturer that combines production with engineering support. Here, we can provide you with services for thermoformed housing that are similar to those provided by injection molding technology. We can assist you in swiftly manufacturing reasonably priced, superior mold components since we have tried-and-true thermoforming procedures and skilled thermoforming operators.

- Free DFM Reports

- 100% Part Inspection

- Direct Delivery to You

- High Precision & Efficiency

- No Minimum Order Quantity

- Competitive & Affordable Price

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Robust Thermoforming Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Mold Design & Engineering

Injection mold design is a key element of the injection molding process as it plays an important role in determining the quality and precision of the final injection molded parts. NOBLE has a professional design team to provide you with the best injection mold design solutions.

- 10+ years of Mold Design & Engineering

- State-of-the-Art Equipment

- 1-to-1 Quote Analysis

- Free DFM Feedback

- Strong R & D capability

- Free DFM and Mold Flow Analysis Report

Mold & Prototype Manufacturing

Once the mold design is approved, we begin manufacturing the mold. We then perform prototype injection molding to quickly and efficiently produce and test them for small batch production of plastic parts.

- 10+ Years of Mold & Prototype Manufacturing

- Thousands of resins to choose from

- Competitive & Affordable Price

- State-of-the-art Equipment

- 100% Part Inspection

- Fast Lead Time

Low-Volume & Medium Injection

NOBLE meets your small and medium batch injection molding needs through strict tolerance control, quality inspection, and complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium & Low Injection Molding

- Competitive & Affordable Price

- State-of-the-art Equipment

- Guaranteed Consistent Quality

- 100% Part Inspection

- Fast Turn-Around Production

Why Choose Us for Custom Thermoforming Services

When considering custom thermoforming services, selecting the right provider is crucial for ensuring quality, efficiency, and satisfaction. Here are several compelling reasons why you should choose us.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Thermoforming Tolerances and Standards

The thermoforming process is widely used for creating various products, from packaging to automotive components. Understanding tolerances and standards in thermoforming is crucial for ensuring product quality and functionality.

| ACTIVITY | TOLERANCE | GUIDELINE |

FORMED MEASUREMENTS <6″ 6″-12″ 12″-18′ >18″ | +/-0.015″ +/-0.025″ +/-0.030″ +/-0.030″ +/-0.002″per inch | Tolerance and size increase proportionally |

| DRILLED HOLE DIAMETERS | +/-0.005″ | Holes Equal or Lesser than 1″ |

| DRILLED HOLE DIAMETERS | +/-0.010″ | Holes from 1″ to 5″ |

| SLOTS | +/-0.010″ | Slot Equal to or Lesser than 1″ Any Direction |

| SLOTS | +/-0.020″ | Slots Greater than 1″ |

| 5 AXIS TRIM | +/-0.015″ | Trim Features under 5″ |

| 5 AXIS TRIM | +/-0.020″ | Trim Features Greater than 5″ |

Materials for Custom Thermoforming Parts

Thermoforming is applied to produce food packages, aircraft components, toys, pallets, and other plastic items. Hence, manufacturers must consider a diverse range of plastic materials before production. Here are the commonly used materials for thermoforming.

Polypropylene (PP)

The most often used plastic for thermoforming is PP. It is frequently utilized in the production of toys, ventilators, packaging, and other plastic products. The inherent qualities of polypropylene, such as its superior resilience to heat, fatigue, and chemicals, make it useful.

Polyethylene Terephthalate (PET)

PET offers excellent chemical resistance, a high degree of impact resistance, tensile strength, and very good alcohol and essential oil barrier qualities. It is frequently used for water bottles, carbonated drinks, and a variety of culinary items.

High-Density Polyethylene (HDPE)

HDPE is renowned for its resistance to water, chemicals, and ultraviolet light. It is a strong thermoplastic that can be used to make plastic bags, pipes, containers, blown bottles, and packaging film.

Polycarbonate (PC)

Polycarbonates are strong, tough materials that can undergo large plastic deformations without cracking or breaking. They have high electrical insulating qualities and are resistant to heat and flame.

Surface Finishes for Thermoforming

Surface finishes in thermoforming play a critical role in the aesthetics and functionality of the final product. The surface finish of the mold directly affects the surface quality of the formed part. Here are some common types of surface finishes used in thermoforming:

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

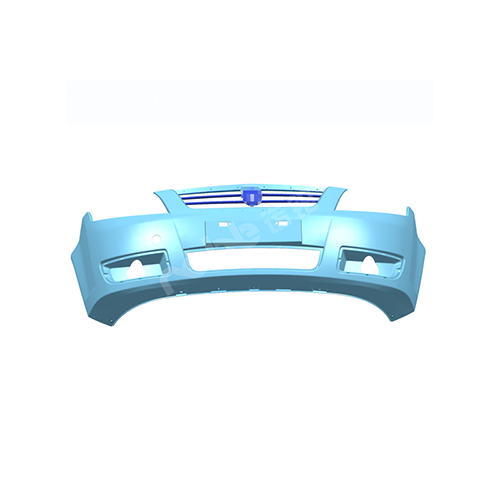

Custom Thermoforming Parts Display

Please take a look at our customized precision thermoforming parts for valued customers, from prototype design to thermoforming molding, to obtain impeccable surface treatment and stable performance of thermoforming parts at competitive prices.

See What Our Customers Say About Us

NOBLE has been engaged in thermoforming services for over ten years and has served many overseas customers. Customers’ words are more substantively representative than the company’s statement–see the objective evaluation of our satisfied customers.

Aaron Nave

Tooling Engineer

I have recently been in business with NOBLE and was thoroughly impressed by their impeccable service. Their dedicated staff helped us with all our needs and made sure we met our deadlines. Do take a look at what they have to offer, they are a very reliable company to be in business with!

Senior Engineer

Dave stashko

As a Mechanical Engineer, it’s always a pleasure to receive parts that look exactly like my CAD design. Great quality and precision on the parts, and finishing options such as sandblasting, anodizing, and silk printing are great (and all that for really good pricing). Good communication throughout the orders which makes things easy! NOBLE is professional, parts are well-packed for shipping. Recommend!

Designer

Andy Mandarino

I’ve been working with Kevin and the team for 3 years now for prototyping and early-stage development, and it couldn’t have been better. On-time, professional, fast turnaround, continuous availability and updates, and most importantly, extensive review before any part is put into production. I am always impressed by the tight tolerances achieved even on the largest parts

Project Engineer

Greg Reginelli

The NOBLE team is great. Great communication, fast response times, and the quality show in the end product. They have a strong engineering background and aren’t afraid of challenging projects. It is rare to find fast and affordable prototypes so it is very much worth quoting a project with them.

Thermoforming Applications

Thermoforming plays an important role in parts manufacturing in automotive, aerospace, electronics, appliances, telecommunications, and medical equipment. NOBLE specializes in providing cutting-edge manufacturing solutions for various industrial applications. Our focus is on delivering superior quality parts at competitive prices to valued customers across multiple industries.

Oil & Gas

Thermoforming plays a vital role in making it an ideal manufacturing process for components used in solar power generation, wind energy, electric vehicles, energy storage, hydrogen fuel cells, and energy-efficient solutions. As the demand for sustainable energy technologies continues to grow, Urethane casting will remain a key enabler in the production of critical components for new energy applications.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Thermoforming's ability to produce complex shapes, maintain tight tolerances, and deliver high-quality finished parts makes it an ideal manufacturing process for numerous automotive components. The efficiency, cost-effectiveness, and versatility of thermoforming contribute to the continuous advancement and innovation in the automotive industry. Common parts include gears, cylinders, gladhands, transfer cases, small engine parts.

Aerospace

Thermoforming's ability to produce complex shapes, maintain tight tolerances, and deliver high-quality finished parts makes it an ideal manufacturing process for numerous automotive components. The efficiency, cost-effectiveness, and versatility of thermoforming contribute to the continuous advancement and innovation in the automotive industry. Common parts include gears, cylinders, gladhands, transfer cases, small engine parts.

Medical Devices

The precise and durable characteristics of thermoforming components contribute to the safety, functionality, and effectiveness of medical devices and equipment. Common parts like forceps, clamps, retractors, and scalpel handles, prosthetic limbs, joint implants, and fixation devices.

Robotics

Thermoforming offers numerous advantages in the robotic industry, including the ability to produce complex geometries, high precision, cost efficiency, and integration of functional features. These advantages contribute to the development of robust, efficient, and high-performing robotic systems capable of meeting the demanding requirements of automation and industrial applications. Common parts include robot frames and housings, motor housings, joints and linkages, etc.

If you are looking for a rapid prototyping manufacturer or a thermoforming shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice. Our well-trained and experienced staff manufactures parts in line with drawings on modern thermoforming, with the highest accuracy and manufacturing quality in all sizes. In addition, we provide professional design considerations for your thermoforming projects.

Want the most professional and fastest service for your thermoforming project? Upload your CAD files now and obtain a quote!

Thermoforming FAQs

The process uses a thermoforming machine to heat and stretch the pliable thermoplastic sheet over the mold. Modern thermoforming machines are generally equipped to handle the trimming and cutting process, while for more conventional machines, trimming and cooling may be done externally.

Thermoforming stands out for its remarkable cost-effectiveness in various ways. Firstly, it boasts low tooling costs, making it accessible to businesses of all sizes. Additionally, thermoforming is highly material-efficient, reducing waste and contributing to sustainability.

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product.

There are multiple types of thermoforming processes but the two most popular, include vacuum forming and pressure forming (we also provide drape forming services and more). Both types are very similar in process, but they each have advantages and disadvantages.

Extrusion creates product continuously through the constant rotation of the resin compressing screw. The process uses a die that molten plastic is pushed through to create a specific shape and thickness. Thermoforming is a manufacturing process by which a plastic sheet is heated until it can bend.