Titanium

Custom Titanium Machining Service

NOBLE provides innovative solutions for titanium CNC machining, from prototype design to manufacturing, high-precision, high-strength titanium alloy parts or prototypes at a competitive price to ensure stability in harsh environments.

- Advanced Equipment & Cost-Effective Price

- 10+ years of Titanium Machining Service

- ISO 9001 & ISO13485 Certified Factory

- Instant Titanium Machining Service Quotes

- Fast Turnaround in 7 days

- Tolerance as tight as ±0.01 mm

Our Titanium Machining Capabilities

Titanium is a highly sought-after material in CNC machining due to its outstanding properties, including high strength-to-weight ratio, corrosion resistance, biocompatibility, and excellent performance in extreme environments. CNC machining can accurately and efficiently manufacture titanium parts, and titanium is 40% stronger than steel. These unique properties make it an ideal choice for solving engineering challenges faced by the medical, aerospace, energy, and chemical processing industries.

| Price | $$$$$ |

| Lead Time | < 8 days |

| Wall Thickness | 0.75 mm |

| Tolerances | ±0.005″ (±0.110mm) |

| Max Part Size | 200 cm x 80 cm x 100 cm |

| Available Titanium at NOBLE | Grace 2, Grace 5, Grace 9, Grace 12, Grace 23, Titanium Ti-15-3, Ti-6Al-2Sn-4Zr-6Mo |

Characteristics of Titanium Machining Materials

Titanium is one of the most versatile and high-performance materials for CNC machining. Its unique properties, including high strength-to-weight ratio, excellent corrosion resistance, and outstanding performance in extreme conditions, make it an ideal CNC machining material for industries such as aerospace, medical, automotive, and marine. However, titanium’s unique characteristics also present specific challenges that require advanced CNC machining techniques and specialized tools.

| Features | Info |

| Subtypes | Grade 1 Titanium, Grade 2 Titanium |

| Process | CNC machining, sheet metal fabrication |

| Tolerance | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

| Applications | Aerospace fasteners, engine components, aircraft components, marine applications |

| Finishing Options | Media Blasting, Tumbling, Passivation |

Pros and Cons of Titanium for CNC Machining

Titanium is a prized material in CNC machining, renowned for its exceptional strength, lightweight properties, and resistance to extreme conditions. Its unique combination of features makes it indispensable in industries such as aerospace, medical, automotive, and marine engineering. However, titanium’s characteristics also present challenges, making its machining a complex and specialized process. Below is a comprehensive overview of titanium’s advantages and disadvantages as a CNC machining material.

Light Weight

Titanium combines exceptional strength with a lightweight structure, making it an ideal material for applications that require strength without adding unnecessary weight, such as in aerospace, automotive, and high-performance engineering.

Low Thermal Expansion

Titanium has a low coefficient of thermal expansion, meaning it maintains its shape and size even with temperature changes. This stability is essential for CNC Machining, where dimensional accuracy is vital, even in fluctuating thermal environments.

Biocompatibility

Due to its high biocompatibility and non-toxic nature, titanium is widely used in the medical field for implants and surgical instruments, offering a safe and effective solution that minimizes the risk of rejection or adverse reactions in the human body.

Durability

Renowned for its outstanding durability, titanium is perfectly suited for CNC-machined parts that must endure demanding conditions. It withstands high-stress, extreme temperatures, and abrasive forces, ensuring longevity and reliability in critical applications.

Non-magnetic

Titanium is non-magnetic and has excellent resistance to oxidation, which makes it highly resistant to corrosion and rust. This unique combination of properties is crucial for components used in sensitive or extreme conditions, including aerospace, medical, and marine applications.

Corrosion Resistance

Titanium excels in resisting corrosion, even in the most chemically aggressive environments. Its remarkable resistance to rust, oxidation, and other forms of corrosion makes it the material of choice for marine, chemical processing, and industrial applications.

Lower Thermal Conductivity

Due to titanium’s low thermal conductivity, managing heat buildup during machining is critical. Excessive heat can accelerate tool wear and negatively impact the quality of the cut surface, making temperature control a key factor in titanium processing.

Increased Cutting Forces

The machining of titanium alloys requires higher cutting forces compared to other materials. This can result in greater tool wear, the potential for part defects, and vibrations, all of which can compromise both the quality and surface finish of the final product.

Residual and Hardening Stresses

Titanium alloys have a unique crystalline structure that limits flexibility during machining. This characteristic increases cutting forces and the likelihood of residual stresses, which can affect the overall performance and precision of the machined part.

High Chemical Reactivity

Titanium’s tendency to react with gases can lead to surface oxidation and embrittlement, weakening the material. This reaction reduces its corrosion resistance, potentially compromising the performance and longevity of titanium components in certain environments.

Types of Titanium Machining Materials

Titanium is a versatile metal widely used in CNC machining due to its unique properties, including a high strength-to-weight ratio, corrosion resistance, and excellent performance in extreme conditions. Different grades of titanium are engineered to meet the diverse requirements of industries such as aerospace, medical, automotive, marine, and energy. These grades are classified into two main categories: commercially pure titanium and titanium alloys. Below is a detailed overview of the types of titanium machining materials.

Titanium Grace 2

This is commercially pure, offering excellent corrosion resistance and moderate strength. It’s used in marine, chemical processing, and medical applications where formability and corrosion resistance are key.

Yield Strength(MPa): 345~450

Elongation at Break(%): 20~25

Hardness(Brinell): 130~160HB

Density(G/m³): ≈ 4.43

Maximum Temp:650~840℉

Titanium Grace 5

Commonly used in the automotive parts. Its high strength and low density can reduce the quality of the body and improve the performance of the car. It also has heat-resistant, wear-resistant and other characteristics, which can meet the requirements of the use of automobiles in complex working conditions

Yield Strength(MPa): 880~950

Elongation at Break(%): 10~15

Hardness(Brinell): 100~350HB

Density(G/m³): ≈4.43

Maximum Temp: 1020~1560℉

Titanium Grace 9

Balances strength, corrosion resistance, and formability, making it ideal for aerospace, automotive, and marine applications, where moderate strength and lightweight characteristics are essential.

Yield Strength(MPa): 220~650

Elongation at Break(%): 15~25

Hardness(Brinell): 200~250HB

Density(G/m³):≈ 4.48

Maximum Temp:1020~1200℉

Titanium Grace 12

Offers superior corrosion resistance, especially in aggressive chemical environments. It’s used in chemical processing, and heat exchangers, where high strength and corrosion resistance are crucial.

Yield Strength(MPa): 550~700

Elongation at Break(%): 15~25

Hardness(Brinell): 200~250HB

Density(G/m³):≈ 4.5

Maximum Temp:1020~1300℉

Titanium Grace 23

This is a low-impurity version of Grade 5, offering improved ductility and fracture toughness, commonly used in medical implants and aerospace applications requiring higher toughness and biocompatibility.

Yield Strength(MPa): 880~900

Elongation at Break(%): 15~20

Hardness(Brinell): 300~350HB

Density(G/m³):≈ 4.43

Maximum Temp: 1620~1650℉

Titanium Ti-15-3

This is a high strength alloy commonly used in aerospace and military applications. It has exceptional strength and excellent corrosion resistance at high temperatures, making it ideal for turbine blades and airframe components.

Yield Strength(MPa): 850~950

Elongation at Break(%):10~20

Hardness(Brinell): 330~400HB

Density(G/m³):≈4.48

Maximum Temp:1560~1740℉

Titanium Ti-6Al-2Sn-4Zr-6Mo

This is a high performance alloy commonly used in automotive components, aerospace and military industries. It performs well in high-temperature environments and has excellent strength, fatigue resistance and thermal stability.

Yield Strength(MPa):930~1000

Elongation at Break(%):8~12

Hardness(Brinell): 330~400

Density(G/m³):≈4.48

Maximum Temp:1700~1830℉

Surface Finishing Options for Titanium Machining

Surface treatments enhance the durability and aesthetics of custom titanium parts, providing additional protection against corrosion and wear. At NOBLE, we use a variety of surface treatments, such as polishing, tumbling, and brushing, to meet your specific requirements for appearance and functionality.

As Machined

Coming out of the machine after machining, our parts are cleaned of any sharp edges and burrs while retaining marks. Without any added material, the part had a surface roughness of 3.2 μm (126 μin).

Polishing

Working on metal and hard plastics, our polishing uses highly efficient machinery to get our parts between Ra 0.8~Ra0.1 for a cleaner surface.

Sand Blasting

Sand blasting cleans the surface of any impurities and peels coating through the propelling of blast media streams over the parts.

Tumbling

Tumbling titanium smooths its surface, often resulting in a matte finish. It’s used for deburring or preparing titanium parts for further finishing or aesthetic enhancement.

Laser Carving

Helpful in brand recognition or parts organization, we use laser carving that applies various printing methods during full-scale production to quickly embed barcodes, lettering and logos on the parts.

Alodine

We use chromate conversion coating or alodine to protect aluminum and other materials from corrosive elements, usually done before priming and painting parts.

Anodizing

To increase surface hardness and dissipate heat, we use anodizing techniques to enhance the look of parts and blend well for painting and priming.

Powder Coating

We apply a thin layer of protective polymer with the corona discharge phenomenon to give our part a lasting finish that protects from impacts and prevents wearing down.

Brushing

Our brushing technique uses abrasive belts over the material to create diverse patterns that match the parts’ structure and color.

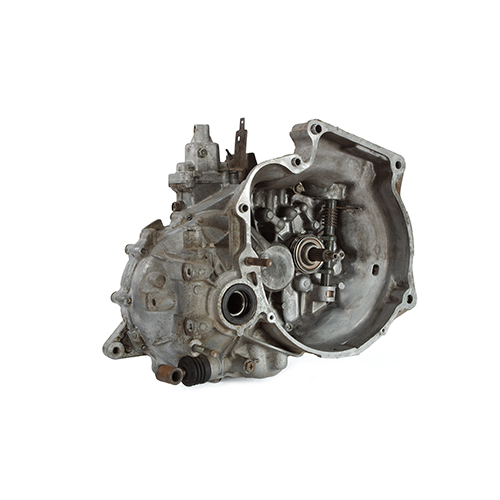

Custom Titanium Machining Parts Display

Check out our over a decade of precision custom titanium machined parts, including precision machined prototypes and parts from our valued customers.

Applications of Titanium CNC Machining

CNC-machined titanium parts are extremely versatile and can be used in a wide range of industries. The inherent precision and accuracy of the CNC machining process enable the production of sophisticated and complex titanium parts to tight tolerances. Titanium’s high strength-to-weight ratio, corrosion resistance, biocompatibility, and heat resistance make them an ideal choice for demanding applications in a variety of industries including aerospace, medical, automotive, marine, and energy.

Aerospace Parts

Titanium CNC machining is widely used in aerospace for manufacturing lightweight, high-strength components like turbine blades, engine parts, fasteners, and airframes. Titanium’s strength-to-weight ratio, corrosion resistance, and high-temperature tolerance make it ideal for demanding aerospace applications that require both durability and performance under extreme conditions.

Automotive Parts

In the automotive industry, titanium CNC machining is used to produce high-performance parts such as engine components, exhaust systems, suspension parts, and wheels. Titanium’s lightweight nature and superior strength help reduce vehicle weight while enhancing performance, durability, and fuel efficiency in high-performance.

Medical Devices

Titanium CNC machining is essential in the medical industry for producing implants, prosthetics, and surgical tools. Titanium's biocompatibility, corrosion resistance, and strength make it ideal for long-lasting, safe, and durable medical devices that can withstand the human body’s harsh environment without causing adverse reactions or infections.

New Energy

Titanium CNC machining is applied in the new energy sector for manufacturing components in wind turbines, solar panels, and geothermal systems. Titanium’s resistance to corrosion and ability to withstand harsh environments make it a preferred choice for energy systems that require reliable performance over long periods, especially in challenging conditions.

Robotics Parts

Titanium CNC machining is used to create lightweight yet strong components for robotics, such as arms, frames, and gears. Titanium's high strength-to-weight ratio and resistance to fatigue make it ideal for robotics parts that need to perform accurately and endure repetitive movements without compromising structural integrity or performance.

Chemical Industry

Titanium CNC machining is vital for manufacturing parts used in the chemical industry, such as heat exchangers, reactors, and valves. Titanium’s outstanding resistance to corrosion and its ability to withstand harsh chemicals and high temperatures make it the material of choice for components that must endure aggressive environments in chemical processing.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!