Rapid Tooling Service

Our Custom Rapid Tooling Services

Upload your CAD files and get an instant quote online. At NOBLE, we manufacture superior rapid tooling solutions for prototypes and small production runs by fusing our technical prowess, experience, and cutting-edge technology. Our team is well-equipped to handle your rapid tooling and mass-production mold-making requirements.

- No Material Limits

- Fast Delivery to You

- 100% Part Inspection

- High Precision & Efficiency

- Test Production Parameters

- Free DFM & Mold Flow Analysis

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Powerful Rapid Tooling Processes

Providing custom CNC machining solutions at competitive prices, we choose from over 100 materials and 60+ surface finishes to ensure you receive high-precision, structurally complex, and performance-stable parts. Try our precision CNC machining services and become our next satisfied customer.

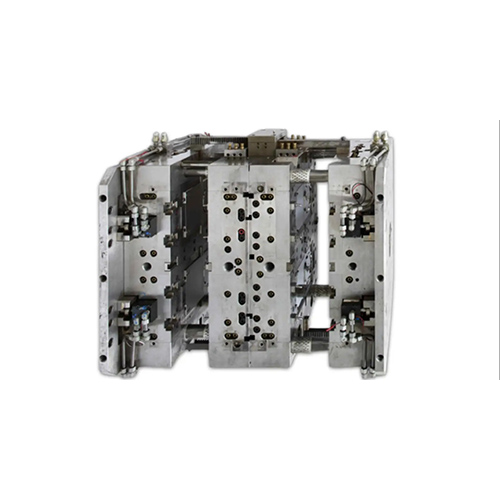

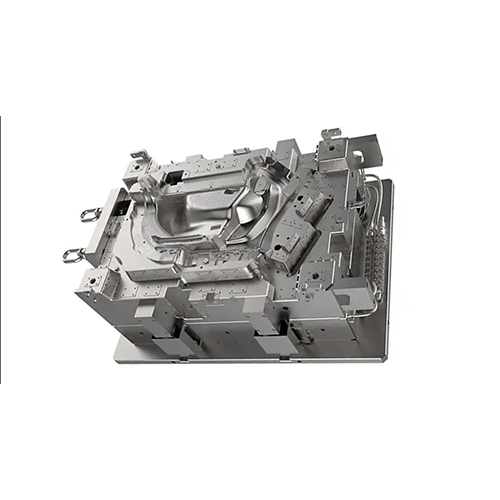

Machined aluminum or soft steel mold cavities are the keys to getting injection molds done fast for low-volume moldings. Simplify the mold design; additional acceleration can be achieved by using stock mold bases and components.

We have more than ten injection molding machines available for prototypes or small-batch molding in addition to standard production molding. Without any delay, the molds will be put onto the machines.

Our Robust Rapid Tooling Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Mold Manufacturing

After mold design approval, we start manufacturing the mold. Then produce samples to test whether they are qualified.

- Free DFM Feedback

- Quote Within 24 hours

- Fast Turnaround in 7 days

- 10+ Years of Mold Making

- State-of-the-art Equipment

- Competitive & Affordable Price

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Custom Rapid Tooling Services

NOBLE uses advanced technology and has a team of skilled professionals who are dedicated to putting our customers first. Our rapid tooling services are precise, efficient, cost-effective, and produce high-quality results. By choosing our rapid tooling services, you can elevate your business to new levels of success.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Materials for Custom Rapid Tooling

Aluminum and steel are common rapid tooling materials. These are cost-effective and high quality material. Details are as follows:

.jpg 500w, https://www.uprojectspartner.com/wp-content/uploads/2024/10/aluminum-mold-(5)-300x300.jpg 300w, https://www.uprojectspartner.com/wp-content/uploads/2024/10/aluminum-mold-(5)-150x150.jpg 150w)

Aluminum Mold Tooling

Aluminum mold tooling is a cost-effective method of producing molded parts and is a perfect choice for prototyping. Aluminum molds can cut cycle times by up to 40% and tooling costs by 15–25% when compared to other mold materials since they are easy to cut. For our clients, this means a quicker turnaround.

.jpg 500w, https://www.uprojectspartner.com/wp-content/uploads/2024/10/steel-mold-(5)-300x300.jpg 300w, https://www.uprojectspartner.com/wp-content/uploads/2024/10/steel-mold-(5)-150x150.jpg 150w)

Steel Mold Tooling

Steel is a strong, reliable, and superior tooling material. Steel molds are perfect for high-volume production because they last longer than aluminum molds. Engineering-grade polymers that are wear and corrosion resistant can also be molded using steel.

Our Rapid Tooling Process Workflow

NOBLE’s staff takes your order needs, from quotation to finished parts, as our machines and efficient team ensure you receive your tooling and parts within scheduled lead times. The workflow usually looks like this:

Request Instant Quote

From the moment we receive your inquiry email, our professional engineers will provide a response within 24 hours to ensure a smooth process.

Engineer Evaluation

To ensure we can produce functional molds, we conduct a feasibility review of your design to ensure we can meet the requirements before commencing production.

Mold Flow Analysis

Predictive modeling software helps us understand how the molten material moves and acts within the mold, which helps us make improvements.

Mold Tooling Production

Using your preferred materials enables us to make mold tooling that is of high quality and can readily fit your applications.

Sample Inspection

Sampling will be delivered for you to review prior to manufacturing plastic parts to ensure precision and quality.

Low Volume Production

After the trial production phase, we begin batch production, which uses powerful machining to manufacture parts at fast rates to save on time and costs.

Strict Inspection

We follow international tolerance standards to ensure our parts meet your parameters.

Delivery

As our team handles packaging to secure our parts neatly for transport, we partner with logistics companies to schedule a timely delivery to your region.

Custom Rapid Tooling Parts Display

To achieve flawless surface treatment and steady performance of rapid tooling at competitive costs, please take a look at our customized precision rapid tooling for valued customers, from prototype design to rapid tooling.

See What Our Customers Say About Us

Check the feedback of our valued customers on how we build strong cooperation relationships with our expertise and the best customer service.

Aaron Nave

Tooling Engineer

Communication was prompt, professional, and helpful. Design changes were accommodated quickly and with no hesitation. The completion of manufacturing was very fast and shipment was quick as well. We are very happy with the result and will certainly use NOBLE again in the future.

Senior Engineer

Dave stashko

I was impressed with the sample models I got from NOBLE. Their team worked with me to spot a few issues with the initial design, which saved time and money since we avoided producing parts with the defects. I have put in another order with them. Great to work with.

Designer

Andy Mandarino

I’ve been working with Kevin and the team for 3 years now for prototyping and early-stage development, and it couldn’t have been better. On-time, professional, fast turnaround, continuous availability and updates, and most importantly, extensive review before any part is put into production. I am always impressed by the tight tolerances achieved even on the largest parts

Project Engineer

Greg Reginelli

We are very satisfied with the services provided by NOBLE. Their team is responsive and professional, and the products are always of impeccable quality. Working with NOBLE has been a smooth and pleasant experience, and we highly recommend them to any company looking for custom manufacturing solutions. Thank you for your excellent work!

Rapid Tooling Applications

Rapid tooling plays an important role in parts manufacturing in automotive, aerospace, electronics, appliances, telecommunications, and medical equipment. NOBLE specializes in providing cutting-edge manufacturing solutions for various industrial applications. Our focus is on delivering superior quality parts at competitive prices to valued customers across multiple industries.

Oil & Gas

Rapid tooling plays a vital role in making it an ideal manufacturing process for components used in solar power generation, wind energy, electric vehicles, energy storage, hydrogen fuel cells, and energy-efficient solutions. As the demand for sustainable energy technologies continues to grow, Rapid tooling will remain a key enabler in the production of critical components for new energy applications.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Rapid tooling's ability to produce complex shapes, maintain tight tolerances, and deliver high-quality finished parts makes it an ideal manufacturing process for numerous automotive components. The efficiency, cost-effectiveness, and versatility of Rapid tooling contribute to the continuous advancement and innovation in the automotive industry. Common parts include gears, cylinders, gladhands, transfer cases, small engine parts.

Aerospace

Rapid tooling's ability to produce complex shapes, maintain tight tolerances, and deliver high-quality finished parts makes it an ideal manufacturing process for numerous automotive components. The efficiency, cost-effectiveness, and versatility of Gravity casting contribute to the continuous advancement and innovation in the automotive industry. Common parts include gears, cylinders, gladhands, transfer cases, small engine parts.

Medical Devices

The precise and durable characteristics of Rapid tooling contribute to the safety, functionality, and effectiveness of medical devices and equipment. Common parts like forceps, clamps, retractors, and scalpel handles, prosthetic limbs, joint implants, and fixation devices.

Robotics

Rapid tooling offers numerous advantages in the robotic industry, including the ability to produce complex geometries, high precision, cost efficiency, and integration of functional features. These advantages contribute to the development of robust, efficient, and high-performing robotic systems capable of meeting the demanding requirements of automation and industrial applications. Common parts include robot frames and housings, motor housings, joints and linkages, etc.

If you are looking for a rapid prototyping manufacturer or a rapid tooling shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice. Our well-trained and experienced staff manufactures parts in line with drawings on modern rapid tooling machines, with the highest accuracy and manufacturing quality in all sizes. In addition, we provide professional design considerations for your rapid tooling projects.

Want to get the most professional and fastest service for your rapid tooling project? Upload your CAD files now and obtain a quote!

Rapid Tooling FAQs

Rapid tooling is a tool that uses its specific shape to form products with a certain shape, size and surface accuracy. It is mainly used in large-scale production. Although the production and manufacturing costs of the mold are relatively high, the cost of each product is greatly reduced due to mass production.

The electrodes for EDM, making of marking stamps, production of hybrid patterns for casting, and producing splintering tools are some of the applications of rapid tooling. There are many reasons why you should consider rapid tooling. It is a low-cost, quick, and effective way that will allow you to market parts faster.

There is no limit to material choice. Any plastics available for mass production, including common silicone and rubber materials, can also be used with the rapid tooling process.

Incorporating rapid tooling into the product development process enables manufacturers to validate design and material choices before transitioning to mass production to accelerate product development, iterate quickly, and bring better products to market.

Rapid tooling quickly creates tools and tool inserts for injection molding low-volume, short production runs. Rapid prototyping has the primary purpose of developing one-off prototype parts or products at speed.