Medical Parts

Our Medical Parts Machining Services

With cutting-edge technology, highly skilled technicians, and state-of-the-art machining equipment, from rapid prototyping to mass production of medical products, outperform other CNC machining suppliers at competitive prices. Our expertise, quality, and attention to detail have earned the trust of numerous medical device manufacturers, developers, and designers. We have won the medical production qualification production, escort your medical project quotation with unparalleled processing precision, and assist you to optimize the design, selecting the appropriate process, reducing costs, and achieving rapid mass production.

- Advanced Equipment & Cost-Effective Price

- 10+ years of Medical Parts Processing Services

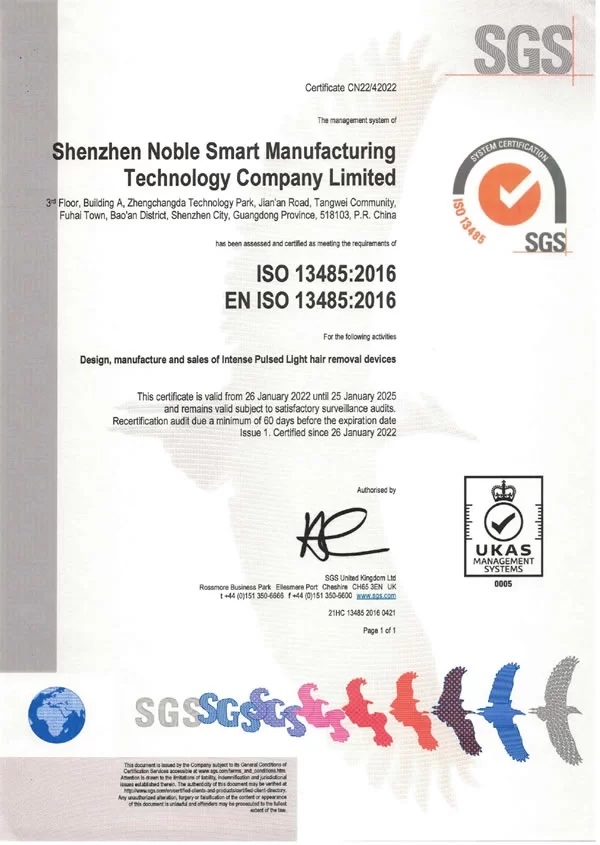

- ISO 9001 & ISO13485 Certified Factory

- Perfect & rigorous quality inspection process

- 24/7 engineering support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Superior Rapid Prototyping Services for the Medical Parts

NOBLE is a reliable manufacturer of medical critical components for surgical instruments and tools, and medical device prototyping. With over 10 years of CNC manufacturing experience, we are powered by our guarantee of the closest tolerances and precision on every machined part. Our skilled machinists can custom machine part designs to the highest standards for all aspects of the medical industry.

NOBLE is fully trusted by customers around the world, and most of them become firm partners after placing orders and receiving finished products that far exceed expectations. Precision medical components manufactured by NOBLE are easily found in trocar/cannula systems, CT and MRI scanner systems, biopsy cutters, respiratory, cardiopulmonary and cardiac equipment, and more.

Our Medical Device Manufacturing

The medical industry relies on precisely manufactured products to maintain human health. NOBLE’s ISO 13485 accreditation demonstrates that we deliver precise, high-quality medical components that meet regulatory and quality standards. Enjoy reliable and professional medical device manufacturing solutions, customizing products with the highest quality standards.

With precision 3-axis, 4-axis, and 5-axis CNC machining centers,fast and pricise cnc machining makes car parts wthin five days.

- Tolerances Down to ± 0.0003 In.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Milling Services

Custom Injection molding parts from prototypes to production parts. Professional engineering assessments and numerous materials and finishes are to be chosen from.

- Tolerances Down to ± 0.0002 In.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- Quick Turn Turning Services

NOBLE’s custom sheet metal prototyping services provide a fast and cost-effective solution to your project from low volume to mass production.

- State-of-the-art Equipment

- 10+ Years of EDM & Wire-Cut

- Fast Turnaround in 7 days

- 1-to-1 Quote Analysis

We successfully translate your concept into physical objects using a variety of secondary processes and sets of contemporary 3D printers.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Grinding Services.

Our Robust Medical Parts Machining Service Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Medical Parts Manufacturing

Digital manufacturing offers the speed and precision required in medical component prototyping and production. Thanks to our strong manufacturing skills and cutting-edge technologies support, engineers and device developers in the medical industry by offering:

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Our On-Demand CNC Machining of Medical Devices

With the high requirements of modern society and technological development, CNC machining is the perfect choice for the medical field. Components used in medical devices often feature complex structures and geometries during manufacturing. We utilize precision CNC machining techniques such as multi-axis CNC milling and CNC turning to create the high precision and tolerances required for medical applications, and combine different CNC machining processes such as injection molding, die-casting, EDM, and wire-cut machining to create complex and incredible parts are used in healthcare systems.

NOBLE is a reliable manufacturer of custom CNC machined components for OEMs in the medical device market. We have gained expertise and acclaim in medical device processing and manufacturing, backed by our leading facilities and well-trained staff. Whether you need rapid prototyping for functional testing or low-volume to high-volume production, we can fully meet your requirements and specifications with our high-speed multi-axis milling centers, CNC turning, fast prototyping equipment, and EDM. Our mission is to advance manufacturing services in healthcare to improve the quality of life for all across the industry!

Precision CNC Machining for Medical Components

NOBLE has always maintained innovation in the precision parts machining industry, progressively progressive, and developed based on the principle of being people-oriented. Over the years, NOBLE has had a wide range of branches in the field of medical precision parts processing, is fully trusted by developers and manufacturers, and gives them project support, Helping them overcome various technical difficulties, and double their performance. Medical products are all processed and manufactured under dust-free and temperature-controlled conditions to ensure that they perform strictly as required when they are used.

CNC Machining for Radiology Equipment Parts

Radiologists work with equipment manufactured to be precise and function properly to ensure accurate results. Therefore, each component had to work clearly, instantly, and efficiently on site. Additionally, they must be durable and mobile, as these machines are often moved from room to room.

Our experts produce high-quality components for radiology equipment, such as anodes for X-ray systems, collimators for CT scans, and details for MRI tables. You can always rely on NOBLE because we have more than ten years of experience in precision parts processing to guarantee the quality of your medical equipment parts.

CNC Machined Components for Surgical Tools and Instruments

As we all know, the job of a surgeon requires extreme care, precision and concentration. NOBLE’s experts bring their skills and expertise to the CNC machining of precision medical micro parts. They fully understand the significance and importance of high-precision parts in medical equipment. Custom titanium implants, gears and other miniature components fabricated by our 5-axis machining experts are used in implantable medical devices, cardiac devices and orthopedic applications.

Types of Medical Parts Machined for Medical Applications

NOBLE has superb processing and manufacturing technology and a wide range of processing materials for medical parts, which can well meet the needs of the medical industry. NOBLE’s technicians are also experienced and knowledgeable in the correct materials for medical product development, and we will work with you to select the materials that best meet your requirements. Below are some of our Noble Materials commonly used to develop medical device parts. Take a look at some of the most popular materials used to develop medical device components.

Titanium

Titanium offers an increased strength-to-weight ratio and higher corrosion resistance, making it ideal for medical device prototyping. It works excellently with 3D printing to create custom parts from patients’ body scans. Titanium also has several properties that offer it increased resistance to chemicals and extreme temperatures.

Stainless Steel

This low-carbon steel is ideal for several kinds of medical components. It is a non-toxic and non-corrosive material that comes in several variants, making it useful for extensive medical applications. While stainless steel is durable on its own, it can also be finished to improve its appearance and mechanical properties.

Silicone Rubber

Silicon rubber offers increased thermosetting advantages. It complies with industry standards due to its high thermal stability and flexibility. Therefore, it can be easily sterilized with various methods. This material is also stable and maintains its flexibility even in extreme conditions.

Thermoplastics

Thermoplastics are highly durable, flexible, and functional materials for medical product manufacturing. They have excellent corrosion, detergent and chemical resistance, making them last longer than other typical medical materials. Thermoplastics are also very adhesive to metals, making them useful for overmolding medical prototypes for improved functionality.

Post-Processing for Medical Prototypes & Products

With NOBLE’s skilled post-processing technology, we can provide your medical prototypes and products with unique surface treatments to meet your product’s aesthetics and chemical and corrosion resistance needs. Depending on material selection and product application, we offer the following finishes.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Sand Blasting

Bead blasting improves the aesthetic appearance of medical devices. It also reduces wear and tear in these components, making them last longer.

Materials: Aluminum, Stainless Steel, Thermoplastics

Color: Gray, black

Texture: Smooth, matte

Passivation

Passivation helps to remove particles from medical components to prevent future corrosion. It impacts adequate corrosion resistance on the products.

Materials: Stainless Steel, Aluminum, Titanium

Color: Yellow, clear blue, green, black

Texture: Smooth, matte, semi-gloss

Heat Treatment

Heat treatment helps to improve the corrosion resistance, strength, and biocompatibility of medical devices.

Materials: Titanium, Aluminum, Stainless Steel

Color: Faint yellow, brown, straw

Texture: Smooth, matte

Advantages of NOBLE CNC Machining Medical Parts

NOBLE provides reliable prototyping and production of medical devices, from simple to complex medical components. Combining advanced technology and exceptional manufacturing expertise, we can bring your medical products to life in the most efficient way possible. No matter the complexity of your part, we can help you achieve your goals through rapid prototyping, bridge tooling, and low-volume production.

Prototyping and Production Solutions for Medical Industry

NOBLE high-volume medical parts precision machining service offers our clients confidence in the products they receive. Thanks to our trusted reputation for meeting exceptional requirements for intricate and highly complex components, we deliver the supply reliability our medical customers can’t live without. We guarantee stringent quality testing. Your manufacturing objectives are met by our on-demand production.

Prototyping

During the early stages of aerospace product development, prototypes play a crucial role in validating designs, making necessary modifications, and selecting suitable materials for automotive components. At NOBLE, we offer technical support throughout your project, ensuring reliable solutions for new product development and manufacturing parts that surpass industry standards, meeting your manufacturing requirements.

Engineering Validation and Testing (EVT)

Enter the engineering verification and testing phase, where you can verify that the functional characteristics of the prototype meet the standard requirements. NOBLE provides 24/7 design and engineering support to give you suitable advice to produce the best product for you at the most reasonable price.

Design Validation and Testing (DVT)

At this point, NOBLE chooses the best material from a variety of materials to design a finish option that satisfies your particular design needs. Durable, high-quality coatings give parts aesthetically pleasing finishes that can withstand market testing.

Production Validation and Testing (PVT)

PVT is the last phase before mass production and it uses sophisticated quality control and manufacturing tools to ready designs for full production. To guarantee optimal production, we'll consider your suggestions and give you the opportunity to make any final adjustments to your model.

Mass Production (MP)

This stage involves the mass production of end-use parts, with a focus on ensuring rapid delivery and precise quality .NOBLE provides meticulous inspections to control quality, secondary machining to meet optimal surface requirements, and precision machined parts that always meet tight tolerances.

Honorary Qualifications We Have Obtained

NOBLE holds ISO 13485:2016 certification, a management system standard for medical device manufacturing. This demonstrates full regulatory compliance for all medical device prototypes and components you receive from us. It also showcases our quality control and assurance system, assuring you that we will manufacture parts to your specific needs. We are ready to serve every client in the dental, biotech, surgical, and pharmaceutical industries and more.

Trusted by Engineers and Designers at Medical Companies

Giving customers a very low-price medical parts machining solution, it is your reliable partner in the expert design of medical components or specific parts, from rapid prototyping to custom production. To help you meet production requirements and industry standards, we provide solutions at the innovation stage.

- Medical manufacturers

- Medical parts manufacturers

- Medical parts plant

- Hospital Beds

- Home Care Beds

- Multi-functional Nursing Bed

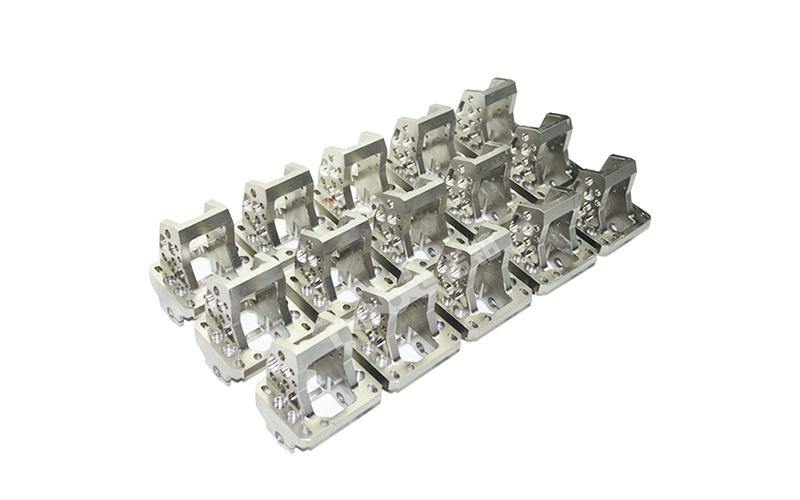

Custom Prototypes and Parts Display

Check out our over a decade of CNC precision medical parts featuring advanced medical device prototypes and parts from our valued customers.

See What Our Customers Say About Us

Customer testimonials are more convincing than company statements. See how we meet customer medical parts machining requirements.

Erkan Arial

Designer

This order couldn’t make me happier. The lead time was really quick in addition to being completed on schedule, and the quality is as promised. The service was truly top-notch. Many thanks to all the guys from NOBLE.

Stuart Weber

President

The components function and look nice. Only the 5 parts were required for this order, which was to remedy a problem with some equipment. We were extremely happy with your quality, price, and delivery, and we will order from you again. I’ve also told friends who run other businesses about you.

Tim Elder

Product Designer

Thanks for the service at NOBLE, which is phenomenal. They have assisted us with great patience and understanding great service as well as the product itself, exactly what we asked for, and works amazingly. especially considering the small details we were requesting. Good looking product.

Aaron Vogler

Project Manager

NOBLE is an important partner for us. The machine medical parts for us with top quality and very patient in consideration of customer requirements. They always deliver on time, whether it’s an old order or a new one. I recommend NOBLE to you.

Medical Parts Machining Applications

Digital manufacturing can speed up development in a variety of ways, Medical parts are used extensively and are still expanding in many sectors. We offer production-grade materials for functional and regulatory testing of medical parts. The following parts for use in medical applications:

- Handheld devices

- Surgical instruments

- Enclosures and housings

- Ventilators

- Implantable prototypes

- Prosthetic components

- Wearables

- Cartridgesf

Medical Parts Machining FAQs

CNC machining is commonly used to produce orthopedic implants like hip and knee replacements, spinal implants, and dental prosthetics. These components need to fit precisely within the patient’s body to ensure comfort, stability, and functionality.

CNC machining is a popular process for manufacturing accurate and high-grade surgical instruments for the medical industry. Common examples of surgical tools used by experts include forceps, blade handles, cutters, surgical scissors, implant holders, biopsy tubes, etc.

This sector utilizes manufacturing processes such as machining, casting, grinding, polishing, metal injection molding and rapid manufacturing. Surgical Instruments & Technologies — One of the largest segments, this includes dilators, sutures and surgical robotics.

The cost of manufacturing a new medical device can vary depending on the complexity of the device, the number of units required, and the chosen manufacturing process. In general, however, the cost of manufacturing a new medical device can range from a few thousand dollars to several million dollars.

NOBLE products have obtained many important certificates such as FDA510K certificate in America. We have certificates of ISO9001-2015 and ISO13485-2016, and Class II medical device production license;

Manufacturers (both domestic and foreign) and initial distributors (importers) of medical devices must register their establishments with the FDA. All establishment registrations must be submitted electronically unless a waiver has been granted by FDA.

The medical device industry covers implants, instruments and equipment intended for therapeutics, monitoring and diagnostics. These include reconstructive devices such as hip and knee replacements as well as implantable monitors for cardiac and diabetic care.