Aluminium Extrusion Services

Our Custom Aluminium Extrusion Services

For high-precision, precise, and complex aluminum extrusion parts with extremely complex geometries, look no further than NOBLE’s aluminum extrusion services. Unparalleled high-precision aluminum extrusion parts manufactured for you at competitive prices with short lead times get an immediate quote.

- Tolerance Down to 0.001mm

- Advanced Equipment & Competitive Price

- ISO 9001 & ISO 13485 Certified Factory

- Lead Time As Fast As 3 Days

- Get an Instant Aluminum Extrusion Quote

- Abundant Aluminum Materials Suppliers

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Powerful Aluminum Extrusion Processes

NOBLE has advanced aluminum extrusion production equipment and experienced engineers, who can assist customers in optimizing designs, selecting appropriate processes, and achieving rapid mass production. We manufacture unparalleled high-precision aluminum extrusion parts at competitive prices and short lead times, get an immediate quote. The following are our common processes for aluminum profile extrusion:

In this process, a high-pressure punch forces billet or heated aluminum through a heated wall container. We often use direct extrusion because of its more critical profile design and superior quality finishing capabilities.

- 100% Part Inspection

- Direct Delivery to You

- High Quality Surface Finish

- Competitive & Affordable Price

We deliver top-quality aluminum extrusions using indirect extrusion, where the blank and container move together while the die is stationary. This approach reduces friction, ensures better thermal control, and results in superior grain structure and mechanical properties.

- 1-to-1 Quote Analysis

- Quote Within 24 hours

- High Precision & Efficiency

- No minimum Order Quantity

We offer hot, warm, and cold aluminum extrusion services. Hot extrusion heats the billet until it recrystallizes, while the hot and cold temperatures are kept below that temperature, increasing the strength and hardness of the aluminum.

- 100% Part Inspection

- Direct Delivery to You

- Quote Within 24 hours

- High Quality and Low Cost

Customized Various Aluminum Profile Extrusion Services

NOBLE has advanced aluminum extrusion production equipment and a team of experienced engineers to manufacture unparalleled high-precision aluminum extrusion parts for you at competitive prices and short delivery times in small batches. Get a quote now.

We combine advanced extrusion technology with precision engineering to produce custom aluminum channels.

- 100% Part Inspection

- Reduced Material Waste

- Standard and Custom Profiles

- Consistency and Corrosion-Resistant

Our aluminum trim combines beauty with functionality. We make embellishments the perfect finishing touch, guaranteeing resilience and visual appeal for every application.

- 100% Part Inspection

- 1-to-1 Quote Analysis

- State-of-the-art Equipment

- 10+ Years of Aluminum Extrusion

Our aluminum trim combines beauty with functionality. We make embellishments the perfect finishing touch, guaranteeing resilience and visual appeal for every application.

- Fast Turnaround in 7 days

- No minimum Order Quantity

- Quick Turn Extrusion Services

- Competitive Price 30% Cost Save

We combine advanced aluminum extrusion technology with precision engineering to produce customized aluminum extrusion dies, integrating beauty and functionality to ensure the stable performance and longevity of each aluminum extrusion die mold.

- Direct Delivery to You

- Quote Within 24 hours

- State-of-the-art Equipment

- Free dimensional inspection reports

Our Robust Aluminum Extrusion Machining Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Custom Aluminum Extrusion Service

Aluminum extrusion is a manufacturing method in which aluminum alloy is pushed through a die with a precise cross-sectional profile. It is used in sectors ranging from construction to consumer electronics. Aluminum extrusion is a simple and quick process that produces lightweight, robust, and corrosion-resistant goods. Here are a few reasons why you should use NOBLE for aluminum extrusion services.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Standard Aluminum Extrusion Profiles

Aluminum extrusion profiles can be customized to fit any 2D cross-sectional shape required. However, there are also standard aluminum extrusion profiles available that can work for a variety of projects, such as extruded aluminum bars and channels in different shapes. Standard aluminum profiles include:

- Circular Bar

- L-Shape

- J-Shape

- I-Beams Extrusions

- Square Bar

- U-Shape

- F-Shape

- Round Tubes and Pipe

- Circular Tube

- T-Shape

- T-Slot Aluminum Extrusions

- T-Bars, H-Bars, Z-Bars

- Square Tube

- C-Shape

- Aluminum Angles Extrusions

- Rectangular Tubes

Post Machining for Aluminum Extrusion

- Profiles

- Milling

- Boring

- Cutting

- Turning

- Tapping

- Drilling

- Grinding

- Deburring

Extruded Aluminum Profiles Standard Dimensions

| Item | Size |

| 1 | 10mm x 10mm |

| 2 | 20mm x 20mm |

| 3 | 30mm x 30mm |

| 4 | 40mm x 40mm |

| 5 | 45mm x 45mm |

| 6 | 50mm x 50mm |

| 7 | 60mm x 60mm |

| 8 | 80mm x 80mm |

| 9 | 100mm x 100mm |

| 10 | 160mm x 160mm |

Note: These are general profiles commonly found in T-slot aluminum extrusions used for framing and other applications. For specific industries or applications like windows, doors, or structural designs, the standard sizes may vary.

Alloys for Custom Aluminum Extrusion Parts

We provide perfect aluminum extrusion solutions at competitive prices, from prototype design to extrusion, ensuring you get high-quality aluminum alloy extrusion parts with high strength and corrosion resistance. NOBLE aluminum extrusion manufacturers produce various grades of aluminum alloys for use in a variety of applications such as electronics, consumer goods, aerospace, automotive, etc. These aluminum alloys have excellent strength, corrosion resistance, formability, etc.

Alloy 6061

Alloy 6061 has excellent weldability, hardness, and corrosion resistance, making it perfect for electrical, marine, and automotive components.

Alloy 6063

The 6063 alloy has a finer grain than 6061 and finishes well. It is heat treatable, economical, and has improved corrosion resistance and strength.

Alloy 7075

7075 is a commonly used aluninum in aircraft and aerospace industries due to its good fatigue strength. However, it may have lower corrosion resistance and average machinability.

Alloy 2024

Favored in aerospace for its high strength-to-weight ratio and fatigue resistance. While weldability is limited, 2024 offers good workability and becomes stronger with heat treatment.

Surface Finishes for Aluminum Extrusion

NOBLE enhances aluminum items with customized surface finishes that improve appearance, hardness, and resistance to damage. Choose from a variety of options to suit your needs.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

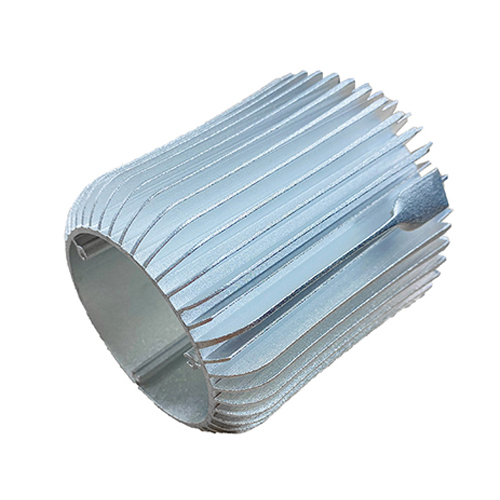

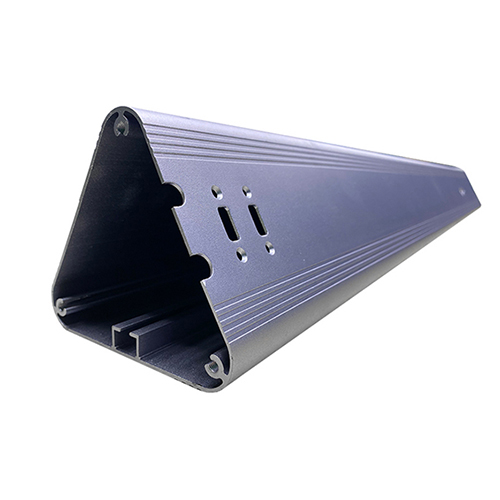

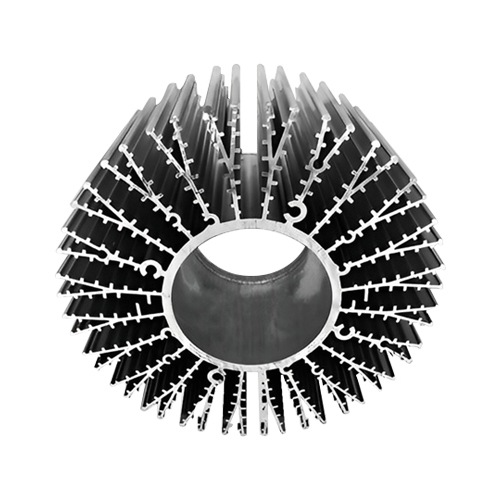

Custom Aluminum Extrusion Machining Parts Display

Check out our extensive gallery showcasing unparalleled high-precision aluminum extrusion parts manufactured at competitive prices for our esteemed customers.

Custom Aluminum Extrusion Part Procedure

The following are some of the fundamental steps in the aluminium extrusion process:

Billet Preparation

Aluminum billets, which are cylindrical logs or bars of aluminum alloy, are used to start the process. To make the billets more flexible for extrusion, they are heated to a certain temperature.

Extrusion

The heated billet is placed in a container known as a "container" or "container sleeve," which is located at one end of an extrusion press. The billet is pushed into the hollow area of the die by a ram, which determines the ultimate shape of the extruded profile.

Die and Tooling

The die is a uniquely shaped opening that molds the aluminum when it goes through it. It has two parts: the "die body," which is fixed, and the "dummy block," which can move. The dummy block manages the aluminum's flow through the die and stops oxides and impurities from getting stuck in the extrusion.

Cooling and Quenching

After the aluminum passes through the die, it emerges as a continuous profile. To maintain its shape, the extrusion is rapidly cooled using air or water. This cooling process, known as quenching, helps the extrusion reach its desired mechanical properties.

Stretching and Straightening

To attain the desired dimensions and flatness, the extrusion may be stretched or straightened. Straightening corrects any bending or bowing in the profile while stretching entails drawing the extrusion through a series of jaws.

Cutting and Final Machining

After extrusion, the material is cut to the necessary length using saws or other cutting techniques. To attain the desired final product characteristics, additional fabrication procedures such as drilling, tapping,CNC machining, or surface treatment may be required.

Strict Inspection

We follow international standards to ensure our parts meet your parameters.

Delivery

As our team handles packaging to secure our parts neatly for transport, we partner with logistics companies to schedule a timely delivery to your region.

See What Our Customers Say About Us

The feedback of customers has a greater impact than a company’s advertising. Take a look at what our satisfied customers have to say about how we met their needs.

CEO

Jackson

I couldn’t be happier with the results of the aluminum extrusion services provided by NOBLE Machining. From theinitial consultation to the final product, their team was attentive, responsive, and knowledgeable. They understoocour design reguirements and delivered parts that met our specifications perfectly. The guality of the machined partswas exceptional, with tight tolerances and smooth finishes. Their commitment to customer satisfaction is evident,and lwill definitely be using their services again in the future.

Principle Engineer

Tom

I am extremely satisfied with the aluminum extrusion services provided by NOBLE Manufacturing. The precision andquality of the machined parts exceeded my expectations. Its team demonstrated excellent attention to detail anddelivered the parts on time. Their expertise and professionalism truly made the entire process seamless. I highly recommend their services to anyone in need of top-notch aluminum extrusion.

Lead Robotics Engineer

Mohamed

We received the CNC parts you created for us, and l finally had a chance to open the box and inspect them today. They look fantastic! I am really pleased with the quality of your components. Small details appear to be quite exactand the briliant siliver anodizina on the aluminum pieces appears to be verv clean and brioht Excellent work. Thank you very much!

Senior Engineer

Jimmy

I recently worked with NOBLE for my aluminum parts project, and l am thoroughly impressed. Their expertise inNC machining is evident in the auality of the final products they delivered. The team at NOBLE paid areat attentiorto detail, ensuring every aspect of the design was accurately machined. They were also proactive in providincsuggestions to optimize the manufacturing process and reduce costs without compromising on guality. Their excellent communication and commitment to meeting deadlines made the entire experience a breeze. highlrecommend NOBLE CNC Machining for anyone seeking reliable and high-cuality aluminum extrusion services.

What is Aluminum Extrusion?

Aluminum extrusion is a method of molding aluminum alloys into long, constant cross-sectional profiles with a consistent shape. The method makes use of aluminum’s malleability and ductility, allowing it to be pushed or dragged through a die to generate the required profile. The resulting aluminum extrusion profiles can be square, rectangular, circular, or have complicated geometries. Because of their lightweight nature, corrosion resistance, and exceptional strength-to-weight ratio, these profiles find applications in a wide range of industries, including construction, automotive, aerospace, electronics and consumer products.

Advantages of Aluminum Extrusion

Aluminum extrusion offers several benefits that make it a preferred choice in various industries. Here are some key advantages of aluminum extrusion:

Aluminum Extrusion Applications

Aluminum extrusion is a critical component of many industries, including automotive, oil and gas, tool and die, aerospace, robotics and medical equipment. NOBLE is committed to providing innovative manufacturing solutions to fulfill our client’s unique needs. Our number one aim is to provide outstanding quality, precision, and efficiency. We provide high-quality parts at competitive costs to customers in a variety of industries.

Oil & Gas

The professionals at NOBLE have a vast understanding of s aluminum extrusion for the oil and gas industry and use top-of-the-line stamping machines to guarantee high precision.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Our sheet metal stamping services enables the production of a wide range of components that contribute to the performance, safety, and aesthetics of vehicles in the automotive industry.

Aerospace

Our stamping services provides high-quality, precise, and durable components that meet the demanding requirements of aircraft safety, performance, and reliability.

Medical Devices

Our sheet metal stamping services have been meticulously designed to meet the stringent requirements of the medical industry, ensuring that every component we produce meets or exceeds the highest standards.

Robotics

Our cutting-edge capabilities, innovative craftsmanship, and skilled engineering team could better serve the robotics field with advanced sheet metal stamping solutions.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Aluminum Extrusion FAQs

The versatility, lightweight nature, corrosion resistance, and design flexibility of aluminum make it a preferred choice in numerous industries where strength, durability, and cost-effectiveness are essential such as automotive, robotic, aerospace, automation.

While steel has a higher yield and tensile strength, the strength-to-weight ratio of a material depends on its density. Aluminum, although not as strong as steel, has a lower density and can still provide comparable strength-to-weight ratios. Aluminum also has unique properties such as corrosion resistance and high conductivity, making it a good choice for various industries. The choice between aluminum and steel depends on specific needs and constraints, and engineering calculations should be made to determine the most appropriate material.

The 6063 alloy is widely used in the production of extruded aluminum due to its favorable characteristics. It is particularly popular for thin walls and architectural applications. A key factor in its popularity is its ease of extrudability and responsiveness to anodizing. Additionally, it produces a smooth and attractive surface finish.

The thickness of an aluminum extrusion can vary depending on several factors, including the specific aluminum alloy being used, the extrusion process capabilities, and the intended application. Generally, aluminum extrusions can range in thickness from very thin walls (less than 1 mm or 0.04 inches) to thicker sections (several inches or more).

It’s “Grade 7075”.

This alloy is part of the 7000 series grades, which are known as the zinc grades due to zinc being the primary alloying element. These grades are the strongest and hardest commercial grades of aluminum. Among them, Grade 7075 is the most commonly used. It’s a high-strength alloy and the strongest of all commercial grades of aluminum.

Normally, aluminum structural profiles are designed for lower weight capacities. However, we have devised specially engineered solutions that can bear a weight of over 2 tons.

Certainly, it’s possible to weld aluminum extrusions. In fact, welding is a widely used technique for connecting aluminum extrusions to form bigger structures or assemblies.