Low-Volume Manufacturing

Our Custom Custom Low-Volume Manufacturing Services

From prototype design to production at competitive prices, with advanced production equipment and a team of experienced engineers, we help customers optimize designs, select appropriate processes, reduce costs, and achieve rapid and small-volume production. Our low-volume manufacturing services ensure you receive high-precision prototypes and superior-quality production parts. Get a quote in minutes and parts within days!

- Advanced Equipment & Cost-Effective Price

- 10+ Years of Low-Volume Manufacturing

- ISO 9001 & ISO13485 Certified Factory

- Get Instant Low-Volume Manufacturing Quotes

- Fast Cycle Time Reduced by 50%

- 24/7 Engineering Support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Powerful Low-Volume Manufacturing Processes

NOBLE has more than ten years of experience in small-batch manufacturing, an excellent team, and strong suppliers to meet all your small-batch manufacturing needs. Based on our many years of experience in small batch molding and excellent engineers, we will effectively execute all your projects involving small batch machining. This is due to the strong supply chain and advanced small-batch manufacturing equipment for different manufacturing technologies. You can rest assured that we will ensure the wholesale price is lower than that of our peers, strictly control the product quality standards, assist customers in optimizing the design, select the appropriate CNC processing technology, reduce costs, and achieve rapid mass production, to ensure that you will finally receive economic and high-precision products.

High-speed, automated cutting can precisely form different shapes to reflect your designs on the metal or plastic material for low volume cnc machining.

- Tolerances Down to ± 0.0003 In.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Machining Services

Plastic injection molding can turn thermoplastic materials into specific plastic parts, whether it is mass production or low volume production.

- 1-to-1 Quote Analysis

- Competitive Price 30% Cost Save

- Functional Testing and Prototyping

- Free Dimensional Inspection Reports

Sheet metal fabrication is a subtractive manufacturing process that can be applied for low volume manufacturing and prototyping of metal parts.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- State-of-the-art Equipment

- Large-scale, Quick Production

Vacuum casting is a custom manufacturing method used for the production of small series of functional plastic parts.

- 24/7 Engineering Support

- Lead Time As Fast As 3 Days

- 10+ Years of Vacuum Casting Service

- Instant Vacuum Casting Services Quotes

Die casting is a manufacturing process in which molten metal is poured or forced into steel molds, allowing for small volume production of quality metal injection molded parts with low cost.

- 7/24 technical support

- 10+ Years of Die Casting

- Instant Die Casting Quotes

- Tolerance down to 0.001mm

We support a variety of extrusion methods, such as aluminum and zinc extrusion, and more to meet your specific requirement of low volume manufacturing or mass production.

- 100% Part Inspection

- 1-to-1 Quote Analysis

- Reduced Material Waste

- High Precision & Efficiency

We offer a wide variety of 3D printing services, such as SLA 3D printing (Stereolithography) and SLS 3D printing (Selective Laser Sintering). Our engineers and project managers will collaborate with you to confirm your CAD designs, product functions, dimensional tolerances, etc.

- Fast Turnaround in 7 Days

- Guaranteed Consistent Quality

- 10+ Years of 3D-Printed Parts

- 24/7 Engineering Support

EDM and wire-cutting are CNC machining processes that use copper, graphite, or molybdenum wire to get the desired design for undercuts, sharp corners, and the removal of unnecessary material from workpieces. EDM is also frequently used to produce mold and rapid tooling.

- State-of-the-art Equipment

- 10+ Years of EDM & Wire-Cut

- Fast Turnaround in 7 days

- 1-to-1 Quote Analysis

Swiss machining is a productive method for creating thin or complex parts. We can always cut the material that is near the workpiece holder by moving the workpiece as well as the active tooling. To prevent distortion in contrast to a conventional CNC lathe.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Swiss Machining Services.

Our Robust Low-volume Manufacturing Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Custom Low Volume Manufacturing

NOBLE has over ten years of low-volume manufacturing services and a robust supply chain. It can produce various parts for you and provide high-quality low-volume manufacturing services. At the same time, we have an experienced team to assist customers in optimizing designs, selecting appropriate processes, reducing costs, and realizing rapid mass production.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Our First Article Inspection Process

When NOBLE receives your order requirements, we will carry out the first article inspection service. According to our company’s regulations, NOBLE will provide the first article inspection service to ensure better completion of your machining project if the order demand reaches 3,000 US dollars or the minimum order quantity is 300 pieces.

| Step 1 | Step 2 | Step 3 | Step 4 | |

| NOBLE | Offer first article inspection | Draft contract | Produce sample | Full-scale production |

| We offer first article inspection services for batch production. | We review the project and contact customers for detailed information. | We produce sample parts according to the FAI agreement and deliver them to you. | The full-scale production starts and finishes production within lead time. | |

| Client | Request inspection | Sign contract | Receive sample | Receive products |

| You request first article inspection for a project that meets our FAI requirements. | You sign the FAI agreement provided by us and agree on our Terms and Conditions. | You receive and examine the parts, inform us of full-scale production may begin. | You receive your prototypes or production parts on the required lead time. |

Low-Volume Manufacturing Capabilities

CNC Machining

CNC machining is used to control a wide range of complex machinery. It is a computerized manufacturing process that uses pre-programmed software and codes to control the movement of production equipment.

Type: Tolerance

Linear dimension: ±0.025mm-±0.001inch

Hole Diameters: ±0.025mm-±0.001inch

Shaft Diameters: ±0.025mm-±0.001inch

Part size limit: 950 * 550 * 480 mm(37.0 * 21.5 * 18.5 inch)

Plastic Injection Molding

Plastic injection molding is the process of melting plastic resins (thermosetting/thermoplastic polymers) and injecting them under pressure into a mold cavity, where they fill and solidify to form the final product.

Standard capabilities: Description

Mold cavity tolerances: ±0.05 mm

Standard lead time: 15 business days or less

Part to part repeatability: ±0.1 mm

Production grade: 1-100,000 cycles

Sheet Metal Fabrication

Sheet metal fabrication converts flat sheets of steel or aluminum into metal structures or products by cutting, stamping, folding, and assembling.

Dimension Detail: Description

Edge to edge, single surface / Edge to hole, single surface / Hole to hole, single surface: ±0.05 inch

Bend to edge / hole, single surface: ± 0.010 inch

Edge to feature, multiple surface / Over formed part, multiple surface: ± 0.030 inch

Production grade: 1-100,000 cycles

Vacuum Casting

Vacuum casting is a manufacturing process where the material goes into a silicone mold with a vacuum to produce complex production parts.

Standard capabilities: Description

Maximum build size: ±0.025 mm-±0.001 inch

Standard lead time: Up to 20 parts in 15 days or less

Dimensional accuracy: ±0.05 mm

Layer thickness: 1.5mm – 2.5mm

Die Casting

Die casting is a process of manufacturing parts by pouring or forcing molten metal into steel modes to create various kinds of parts.

Standard capabilities: Description

Maximum build size: ±0.025 mm-±0.001 inch

Standard lead time: Up to 20 parts in 15 days or less

Dimensional accuracy: ±0.05 mm

Layer thickness: 1.5mm – 2.5mm

Aluminum Extrusion

Aluminum extrusion facilitates the manufacture of complex parts through the process of plastic deformation. Material is forced through a mold or orifice to achieve the desired shape.

Standard capabilities: Description

Press sizes: 450T – 3000T

Standard lead time: 2 weeks for small molds, 4 weeks for larger molds

Minimum order volume: 0.5 ton aluminum for smaller machines, 1.0 ton of 6063 aluminum for larger machines.

Post-processing: Full service CNC cutting, threading, slotting, face milling, etc.

3D Printing

3D printing is a manufacturing process in which a three-dimensional part or object is created from a digital 3D or CAD model.

Standard capabilities: Description

Min. wall thickness: 1.0 mm

Layer height: 50 – 300 μm

Max. build size: 250 * 250 * 250 mm (SLA), 420 * 500 * 420 mm (SLS), 500 * 500 * 500 mm (FDM)

Tolerance: ± 0.5% with a lower limit of ± 0.5 mm (± 0.020″)

Surface Finishes for CNC Machining

CNC machining leaves visible tool marks during the process of removing portions of the block’s surface to create desired shapes. If you don’t want as-machined parts, select a surface finishing for your custom parts. At NOBLE, we offer several common surface finishes that help improve functionality and aesthetics.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Sand Blasting

Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: ABS, Aluminum, Brass

Color: N/A

Texture: Matte

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

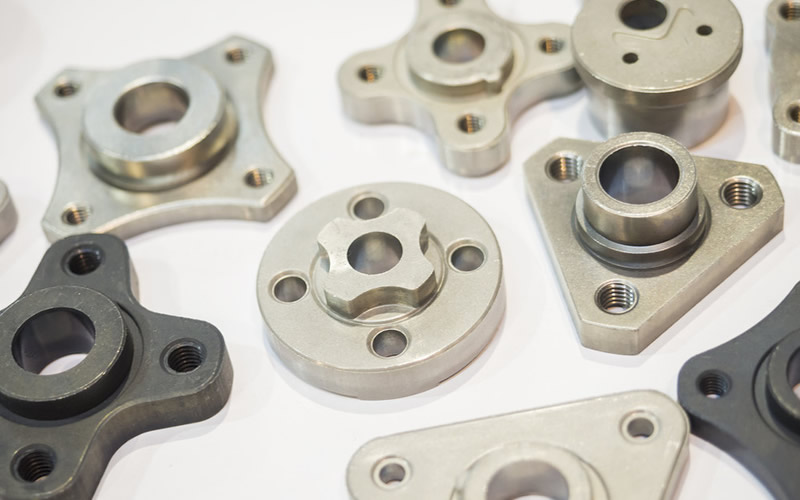

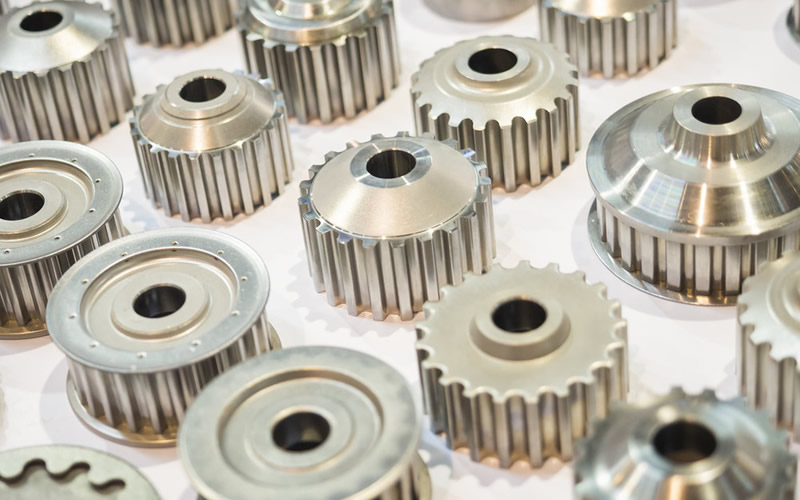

Custom Low Volume Manufacturing Parts Display

Get inspired by our custom projects and contact us to Get Instant Quotes for custom parts starting from 1 pcs.

See What Our Customers Say About Us

NOBLE has been engaged in low volume manufacturing services for over ten years and has served many overseas customers. Customers’ words are more substantively representative than the company’s statement–see the objective evaluation of our satisfied customers.

Mark Alford

Vice President

From the instant and accurate quotation to the production process to the timely delivery of parts, NOBLE responded to our demands with complete professionalism.They handled every aspect of this CNC machining project quickly and cost-effectively.We will surely work with them again in the future.

Piscary Herskovic

Product Designer

NOBLE has been our quality supplier of CNC machined parts.Fast delivery is very important for our business, and NOBLE always offers short lead time and competitive pricing.Andy responds fast to all our emails and questions.This has improved our working relationship, and we continue to value this partnership.

Lisa Craig

Directorof Product Development

The prototype was well received at our event last week. One of our co-workers expressed concern that because rappeared to be so “product-like,” some people would mistake it for the real thing rather than a showcase model.Once more, many thanks for your excellent job in making ideas come to life!

Juraj Kaminski

Mechanical Engineer

Kevin, l want to thank you and your team for all the attention to detai and hard work in getting our part done in justitwo weeks. We were able to get our last order from your courier on time, so we can deliver them to our customerstoday and tomorrow. We highly recommend NOBLE to everyone.

What is Low-Volume Manufacturing?

Low-volume manufacturing is the process that links the development cycle with high-volume production. Low-volume molding enables design improvement and optimization, reducing time-to-market and lower part production costs while reducing risk for cooling projects. Your product manufacturing process can be validated and seamlessly transferred to partner manufacturers for high-volume production when the time comes.

Low Volume Manufacturing Applications

Because CNC machining can achieve high precision without changing the material structure with good manufacturing speed, it is becoming growing common as the range of machines, control systems, and tools for CNC machining continues to expand.NOBLE is dedicated to providing precision machining services for various industries and our precision CNC-crafted parts can be found in all areas of the industry, including.

Oil & Gas

Experts at NOBLE master the comprehensive knowledge of CNC machining for the oil field and gas industry paired with the assurance of high precision offered by top-notch CNC machines.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Low Volume Manufacturing FAQs

Low-volume production typically refers to products produced in small batches with little or no engineering, design, or tooling investment. Small batch production processing is generally considered any order of fewer than 300 pieces, although this number may vary from company to company.

According to NOBLE’s many years of experience, we usually use small batch manufacturing to test products before mass production or when customer demand is small. Low-volume manufacturing processes including injection molding, CNC milling, and 3D printing.

Manufacturing in low volume can shorten the overall production lead time, saving you time and effort during the product development phase. With low-volume manufacturing, you can iterate designs and parts faster to shorten product lifecycles when needed.

NOBLE lists six standard manufacturing processes

Repetitive Manufacturing

Discrete Manufacturing

Workshop Manufacturing

Process (continuous) Manufacturing

Process (batch) Manufacturing

3D Printing