Mold Making Services

Our Custom Mold Making Services

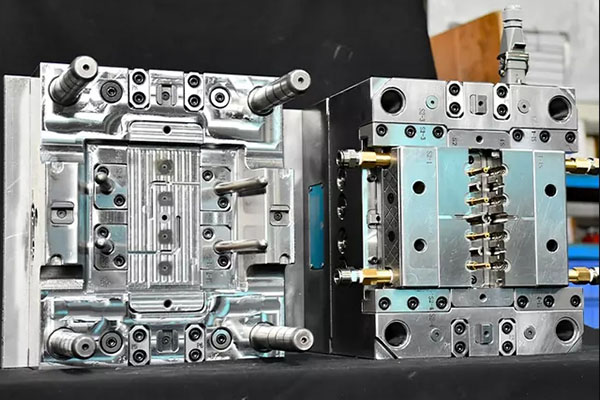

Need mold-making supplies for mass-producing parts? NOBLE is known as the best mold maker in China. We have advanced mold manufacturing equipment and excellent partners. We can provide injection molds for hard plastic, rubber, and silicone, metal injection molds for various precision stainless steel parts, and die-casting molds for aluminum, magnesium, and zinc. NOBLE is lower than the market price, strictly controls the quality of mold production, improves the supply chain, and solves all needs in one stop.

Whether you need prototype tooling for low-volume production or mass-production tooling requiring millions of runs, NOBLE has it covered.

- 10+ years of Mold Making

- 24/7 Engineering Support

- Instant Mold Making Quotes

- Free Dimensional Inspection Reports

- ISO 9001 & ISO13485 Certified Factory

- Advanced Equipment & Cost-Effective Price

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Powerful Mold Making Processes

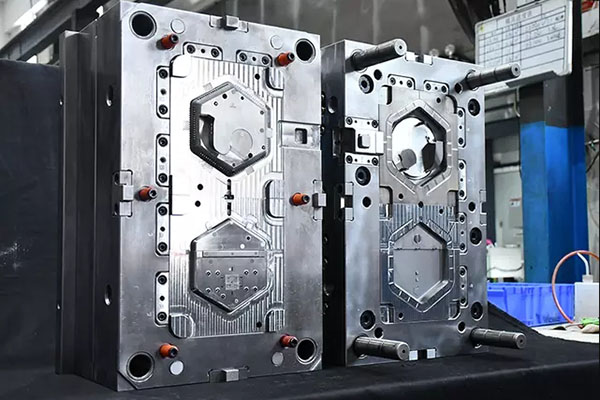

Plastic injection molds are aluminum or steel molds used to make parts from a wide range of plastics, including nylons, acrylics, elastomers, and reinforced materials like glass-filled polyamide. Custom plastic molds can last between 100,000 and 1,000,000 shots.

- 1-to-1 Quote Analysis

- Competitive Price 30% Cost Save

- Functional Testing and Prototyping

- Free Dimensional Inspection Reports

Metal injection molding (MIM) is a form of injection molding where a metal and binder mix is used as feedstock. A metal injection mold is usually made from tool steel to withstand the metal injection, but we can also use aluminum.

- 100% Part Inspection

- Fast Turnaround in 7 days

- 24/7 Engineering Support

- Competitive Price 30% Cost Save

Unlike many prototyping specialists, we can provide metal casting molds (and a low-volume casting service through our partners). These molds — typically made from hardened steel — can be used to make parts from aluminum, zinc, magnesium and other non-ferrous metals.

- 7/24 technical support

- 10+ Years of Die Casting

- Instant Die Casting Quotes

- Tolerance down to 0.001mm

We can make low-cost investment casting molds by 3D printing a wax pattern and surrounding it with ceramic. Ceramic molds can make metal cast parts from aluminum, zinc, magnesium, stainless steel, and more.

- Quote Within 24 hours

- High Quality and Precision

- Versatile and Intricate Shapes

- Accurate and Smooth Surfaces

Our metal die molds can be used for aluminum extrusions of alloys like 6061 and 6063. We also make molds for plastic extrusions of materials like polystyrene, nylon, polypropylene and polythene.

- 100% Part Inspection

- 1-to-1 Quote Analysis

- Reduced Material Waste

- High Precision & Efficiency

Our experience making sheet metal molds for stamping and bending allows us to create sheet metal prototypes.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- State-of-the-art Equipment

- Large-scale, Quick Production

Our Mold Making Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Prototype Machining

From NOBLE, get an online quote with free design analysis in hours to get your CNC machined prototypes done in days.

- State-of-the-art Equipment

- 10+ Years of CNC Machining

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Low-Volume Manufacturing

With advanced production equipment and an experienced team of engineers, we can manufacture products with complex geometric shapes and high precision requirements with strict tolerance control and perfect quality inspection processes.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Medium & Mass Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Custom Mold-Making Services

NOBLE is an experienced mold-making service provider, offering many services beyond competitors:

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Mold Making Processes

Mold-making is a complex process that requires a high level of skill and experience. Although every case is different, a typical order for a set of molds might look like this:

Mold Making Tolerances and Standards

| Process | Materials | Lead Time |

| Plastic Injection Mold | Plastic | Weeks |

| Metal Injection Mold | Metal | Weeks |

| Die Casting Mold | Metal | 5-8 Weeks |

| Investment Casting Mold | Metal | 4-12 Weeks |

| Extrusion Mold | Metal/Plastic | 2-8 Weeks(depends on the complexity of mold) |

| Sheet Metal Mold | Metal | 4-8 Weeks |

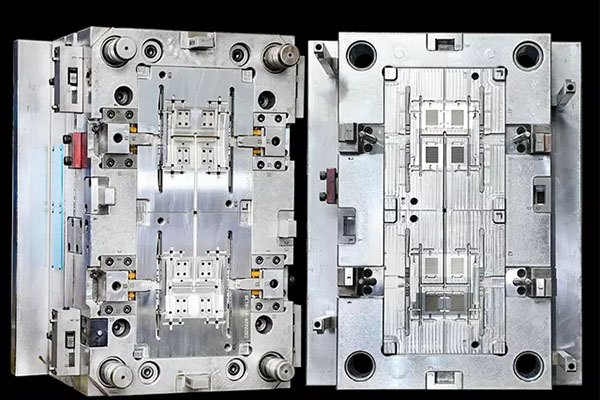

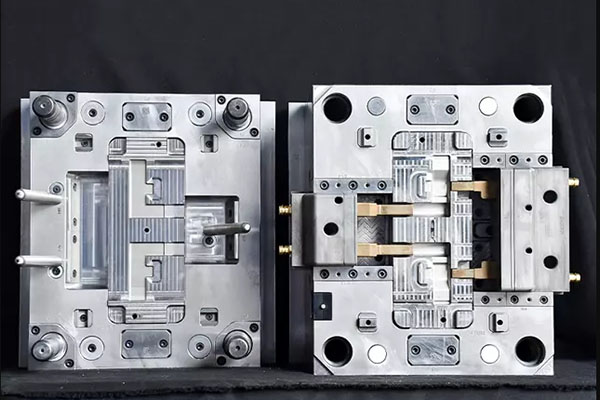

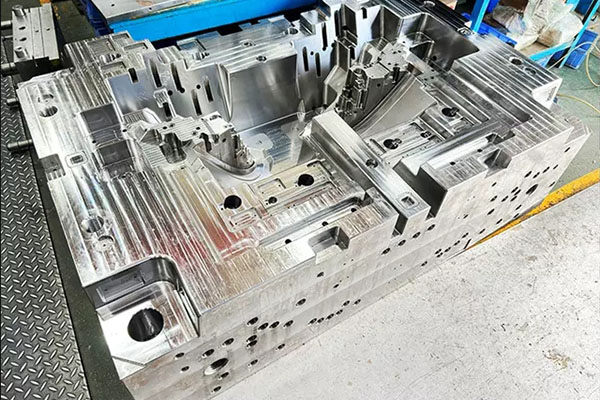

Projects for Custom Making Mold Parts

NOBLE is a professional mold manufacturing company in China, providing a wide range of prototype molds and production molds for most production methods, such as plastic injection molding, metal injection molding, high-pressure die casting, metal casting, aluminum extrusion, and sheet metal. With our strong engineer and manufacturing team, we have successfully produced 10K+ molds and delivered 2 million+ parts to our customers.

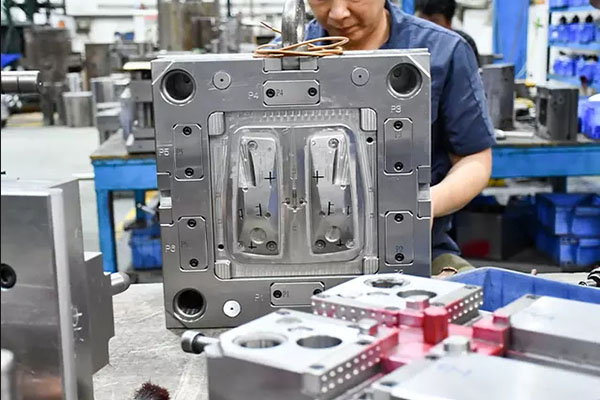

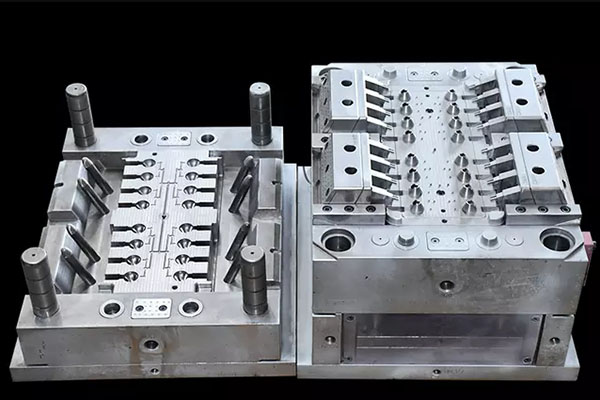

This is a 4 cavities mold we made for PU glasses injection molding. To protect people from being infected during the critical time. We finish the mold within 10 days instead of 4 weeks.

Protect Glasses Mold

This is a 4 cavities mold we made for PU glasses injection molding. To protect people from being infected during this critical time. We finish the mold within 10 days instead of 4 weeks.

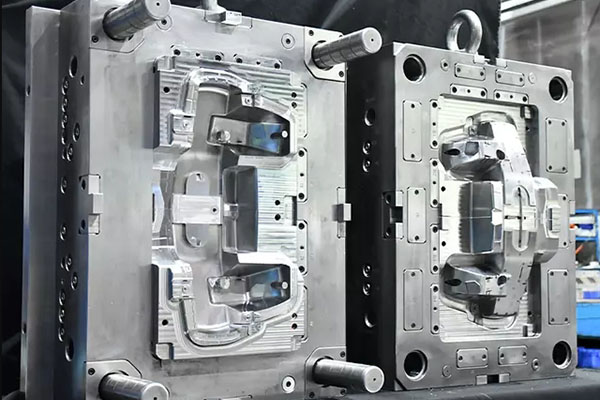

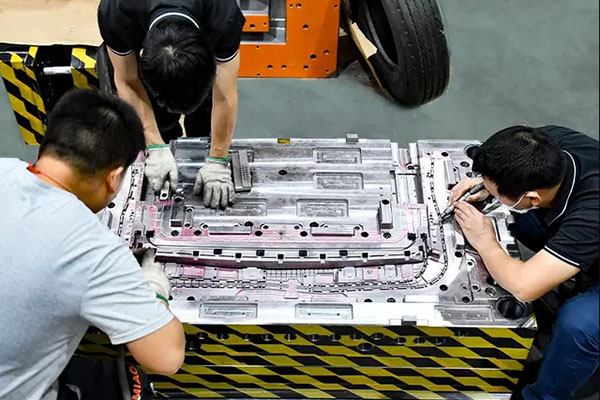

Big Car Component Mold

One of our advantages is we are able to make large size of molds from our CNC and EDM machines, and get the moldings done from our 1500 ton molding machines.

Reflector Mold Core

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Material for Mold Making

We utilize different metals to create the right custom molds. Steel and Aluminum are two common materials used in custom mold making.

Steel

Steel materials are wear-resistant and withstand high pressures, making them durable and ideal for long-term use. It also offers maximum strength for high-volume processes.

Aluminum

Cheaper than steel, aluminum is an excellent option for those looking for an alternative with the same quality as steel. It’s lightweight and has incredible workability, which allows for more design flexibility.

See What Our Customers Say About Us

NOBLE has been engaged in mold making services for over ten years and has served many overseas customers. Customers’ words are more substantively representative than the company’s statement–see the objective evaluation of our satisfied customers.

Stefan Hohmann

Product Manager

Every quarter, we order about 20 plastic cases for our equipment from NOBLE. The enclosure was initially cast in urethane, but Kevin told me about the idea of using aluminum molds, which got me a few hundred molds. We decided to turn to this process. I am delighted with this solution, NOBLE’s suggestion is very good, and the optimized design scheme saves a lot of costs.

Piscary Herskovic

Product Designer

NOBLE has been our quality supplier of CNC machined parts.Fast delivery is very important for our business, and NOBLE always offers short lead time and competitive pricing.Andy responds fast to all our emails and questions.This has improved our working relationship, and we continue to value this partnership.

Hari Mackenzie

Engineer

We asked NOBLE to fabricate parts for a critical supplier demo, and you came through with a short lead time.Your work is always high quality, and we are grateful for your precision in machining components. The help in checking our designs and material selection has also saved our company from making expensive errors.We look forward to doing future projects with you guys.

Mark Alford

Vice President

From the instant and accurate quotation to the production process to the timely delivery of parts, NOBLE responded to our demands with complete professionalism.They handled every aspect of this CNC machining project quickly and cost-effectively.We will surely work with them again in the future.

Mold Making Applications

Because CNC machining can achieve high precision without changing the material structure with good manufacturing speed, it is becoming growing common as the range of machines, control systems, and tools for CNC machining continues to expand.NOBLE is dedicated to providing precision machining services for various industries and our precision CNC-crafted parts can be found in all areas of the industry, including.

Oil & Gas

Experts at NOBLE master the comprehensive knowledge of CNC machining for the oil field and gas industry paired with the assurance of high precision offered by top-notch CNC machines.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Mold Making FAQ

Molds are normally created to duplicate plastic and metal parts. After testing the prototypes and the market, it is the most cost-efficient way to launch your products on a scale.

Generally speaking, it is cheaper to make plastic or metal molds in China than in other countries. But shipping costs should also be considered: if you are pressed for time, you need to use air freight; sea freight is much cheaper, but usually takes 40 days or more.

A well-made, fully hardened steel mold may be used for up to a million shots or injections, depending on the mold shape and injection material. Aluminum molds are less durable, which is good for short-run production with a tight schedule.

Molding designs should avoid sharp corners, inconsistent wall thicknesses, and other features that restrict material flow.

Whatever you decide to use, in the end, what is the best cost-efficient way to get your parts done at the required quality is the key.

Tolerances are very important and if not properly specified and controlled, assemblies will fail. NOBLE uses the ISO 2068-c standard for injection molding tolerances unless tighter tolerances are required.

After placing an order, it takes about 35 days for mold design and production, and 3-10 days for molded parts production.