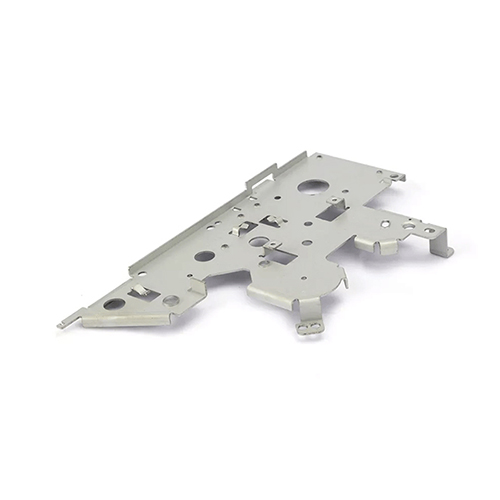

Sheet Metal Stamping Services

Our Sheet Metal Stamping Services

Our sheet metal stamping services manufacture intricate stamping parts accurately and deliver products that surpass customer expectations at an affordable cost and quick turnaround time.

- Tolerance Down to 0.001mm

- 10+ Years Experience in Stamping

- ISO 9001 & ISO13485 Certified Factory

- Lead Time As Fast As 3 Days

- Advanced Equipment & Competitive Price

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Sheet Metal Stamping Processes

Our sheet metal stamping services could design and create progressive dies and four-slide tools, as well as precision machining. We are also able to perform any necessary secondary manufacturing processes, such as deburring and tapping. Our team has a deep understanding of metallurgy, and we are committed to providing exceptional customer support for all of our metal stamping and forming products. We can shape and form your workpiece to the optimal geometry and can achieve precision tolerances down to one-thousandth of an inch.

Progressive die stamping is a productive and automated method used for creating high-volume productions. During manufacturing, a strip of sheet metal is fed through a series of dies, each performing a specific operation on the material. This allows for the simultaneous creation of multiple features, reducing production time and cost.

- Tolerances Down to ± 0.0003 In.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Milling Services

Deep-draw sheet metal stamping is a metal-forming technique that creates seamless, three-dimensional components with significant depth. The process involves using a die and punch set to transform a metal sheet into complex shapes by drawing it into a cavity. This method is commonly used to produce cylindrical or box-shaped parts with high accuracy.

- Tolerances Down to ± 0.0002 In.

- Quote Within 24 hours

- Fast Turnaround in 7 days

- Quick Turn Turning Services

Fourslide sheet metal stamping also referred to as multi-slide stamping or four-way stamping, is a specialized method of metal stamping. The manufacturing process is used to create intricate shapes and complex, small to medium-sized components with multiple bends. It is ideal for parts that require precise forming, tight tolerances, and high-speed production.

- State-of-the-art Equipment

- 10+ Years of EDM & Wire-Cut

- Fast Turnaround in 7 days

- 1-to-1 Quote Analysis

Fine blanking sheet metal stamping is a precise method of forming metal components that produce smooth edges all the way around the workpiece. Unlike traditional blanking, this method only requires one step and a small die clearance. Furthermore, no additional secondary operations are required, reducing both production time and costs. As a result, fine-blanking is a popular manufacturing technique for a variety of products, including automotive, aircraft, and precision machine components.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Grinding Services.

Embossing is a sheet metal stamping technique that produces raised or indented patterns or designs on sheet metal. It entails applying pressure to the material with the desired pattern using a die, resulting in a raised or depressed area. Embossing is frequently used to add decorative or functional features such as grip surfaces or identification marks.

- Tolerances Down to ± 0.0005 mm.

- Competitive Price 30% Cost Save

- Fast Turnaround in 7 days

- Quick Turn Swiss Machining Services.

Compound die stamping is a high-efficiency and low-cost precision metal stamping manufacturing process. It is suitable for small and medium-sized metal stamping projects. It can ensure the precision tolerances required for part design and has a lower manufacturing cost than progressive die molds.

- Quote Within 24 hours

- Competitive Cost Quotations

- Product Design Optimization

- DFM Manufacturability Report

Our Robust Sheet Metal Stamping Capabilities

Sheet Metal Prototyping to Production

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Sheet Metal Prototype Machining

At NOBLE, you can get an online sheet metal fabrication quote and free design analysis within hours, and have your sheet metal fabrication prototype completed within days.

- State-of-the-art Equipment

- 10+ Years of Sheet Metal Manufacturing

- Competitive & Affordable Price

- Quote Within 24 hours

- Free DFM Feedback

- Fast Turnaround in 7 days

Rapid Sheet Metal Prototyping

With advanced production equipment and an experienced team of engineers, our sheet metal prototypes can be produced within a few days at a low unit cost, with strict tolerance control and a complete quality inspection process.

- Competitive & Affordable Price

- State-of-the-art Equipment

- 10+ Years of Low-Volume Manufacturing

- Fast Lead Time

- 30+ Countries shipped

- 100% Part Inspection

Batch Sheet Metal Production

NOBLE meets mass production needs through strict tolerance control, quality inspection, and a complete supply chain, and quickly delivers large quantities of low-cost, stable-performance sheet metal parts.

- 10+ Years of Medium&Mass Production

- Competitive & Affordable Price

- Large Supplier Network

- 100,0000+ Unique parts produced

- Guaranteed Consistent Quality

- Fast Turn-Around Production

Why Choose Us for Custom Sheet Metal Stamping Services

NOBLE prioritizes customer satisfaction by combining cutting-edge technology with the expertise of our skilled professionals. Our Sheet Metal Stamping services are precise, streamlined, cost-effective, and produce excellent results. Choosing our stamping services can help propel your company to new heights of success.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

What is sheet Metal Stamping?

Sheet metal stamping is a cold-forming process that uses dies and presses to apply external forces to plates, strips, tubes, and profiles which makes plastic deformation or separation to obtain a workpiece of the desired shape and size. Sheet metal stamping is a low-cost, high-speed manufacturing method that may create numerous, identical metal parts. The sheet metal stamping process can be used to create high-quality products and is appropriate for both short- and long-term production., and can be performed in conjunction with other metal-forming operations to produce high-quality parts.

Advantages of Sheet Metal Stamping

Sheet metal stamping is a precise, high-speed process that can efficiently form complex metal parts, providing cost-effective production and consistency, especially suitable for large-scale manufacturing. As a sheet metal stamping manufacturer, NOBLE not only has advanced sheet metal stamping equipment and an experienced team of engineers but also can obtain precise and stable sheet metal stamping parts at competitive prices.

Sheet Metal Stamping Production Volumes

Batch sheet metal stamping provides accurate, efficient production of metal parts in smaller quantities, offering flexibility, reduced tooling costs, and quick turnaround for custom or short-run projects. Upload your CAD file and get an instant quote for sheet metal stamping.

Sheet Metal Stamping Tolerances and Standards

Our precision metal stamping services can deliver your part’s desired shape, whether you’re in the aerospace.automotive, telecommunications, or electronics industry. We try to achieve special tolerances as long as you indicateyour requirements for your drawing.

| Minimum Diameters | Aluminum: At least 1.2x the thickness of the materiaStainless Steel: 2x the material thickness |

| Distance From Edges | At least twice the material thickness |

| Distance From Bends | Desian holes or slots less than 0.100″ in diameter or width at a distance of at leasttwice the material thickness (2x MT) plus the radius of the form. |

| Bend Height | 2.5x the material thickness plus the bend radius |

| Bends Close to Edges | At least twice as wide as the material thickness and as long as the bend radius |

| Notches and Tabs | A width of 1.5x the material thickness |

| Corner Radii | At least half the material thickness |

Materials for Sheet Metal Stamping

NOBLE provides a wide range of materials for both our standard and custom metal stampings.

.jpg 760w, https://www.uprojectspartner.com/wp-content/uploads/2024/11/Aluminum-(4)-300x197.jpg 300w)

Aluminum

Aluminium is a metal that is lightweight and has good formability, making it ideal for a variety of stamping applications. It is frequently used in the automotive, aerospace, and electronics sectors. For stamping purposes, aluminum alloys like 5052 and 6061 are frequently employed.

Price: $

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Steel

Steel is the most commonly used material for metal stamping due to its strength, durability, and availability. Various types of steel are used, including carbon steel, stainless steel, and alloy steel. Carbon steel is often used for general-purpose stamping, while stainless steel is preferred for applications requiring corrosion resistance.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Copper

Copper is renowned for its exceptional electrical and thermal conductivity, making it a popular choice for electrical and electronic components. Copper alloys, such as brass and bronze, are utilized for applications that demand increased strength or protection against corrosion.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Titanium

Titanium is a lightweight and high-strength metal with excellent corrosion resistance. It is often used in aerospace and medical industries, where its biocompatibility is also advantageous. Titanium alloys, such as Ti-6Al-4V, are commonly used for stamping applications.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Surface Finishes for Sheet Metal Stamping

NOBLE’s diverse range of surface finishes can help improve the surface qualities of your products. Surface finishes on your customized parts are intended to improve their appearance, surface hardness, and roughness, chemical and corrosion resistance, and other properties. They also help to hide any visible tool marks from areas cut with live tooling. Here are some of your best alternatives.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish

Sand Blasting

Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Materials: ABS, Aluminum, Brass

Color: N/A

Texture: Matte

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin

Custom Sheet Metal Stamping Parts Display

Please browse our extensive gallery showcasing the precision sheet metal stamping parts created by us for our esteemed clients.

See What Our Customers Say About Us

Customers’ feedback is more substantively representative than the company’s statement–see the objective evaluation of our satisfied customers. Feel free to customize the parts to fit your project and business!

Chris Smyth

Project Manager

We have been working with NOBLE for 5 years and they are a trusted partner that will provide us with creativity andguality production of sheet metal stamped parts, We thank them for providing desian enhancement services andfinishing services.They always respond quickly to our requests.

Jamie Cantero

R&D Project Manager

Since our first cooperation in 2018, we have considered NOBLE as our reliable partner. Their sheet metal stampingservices are of excellent quality and they always patiently consider the requirements of their customers. Whether it’sa new order or an old one. we’ve never had a problem with timely delivery. We highly recommend NOBLE to anvonelooking for reliable and top-notch sheet metal stamping services

PaulJoshi

Engineer

We have been working with NOBLE for 3 years and he has proven to be a reliable and valuable partner. During thecolaborative desian process, he alwavs provided expert advice on the best wavs to machining sheet metalstamping parts. We thank him for the excellent level of customer service he consistently provides.

Mark Alford

Vice President

From the instant and accurate quotation to the production process to the timely delivery of parts, NOBLE responded to our demands with complete professionalism.They handled every aspect of this CNC machining project quickly and cost-effectively.We will surely work with them again in the future.

Sheet Metal Stamping Applications

Sheet metal stamping is a crucial aspect of parts manufacturing in various industries such as automotive, aerospace, electronics, appliances, telecommunications, and medical equipment. NOBLE is dedicated to offering innovative manufacturing solutions to meet the diverse needs of our clients. Our top priority is to provide high-quality parts at competitive prices to customers across multiple sectors.

Oil & Gas

The professionals at NOBLE have a vast understanding of sheet metal stamping techniques for the oil and gas industry and use top-of-the-line sheet metal stamping machines to guarantee high precision.

Automation Equipment

NOBLE Rapid Prototyping service allows you to quickly and easily create automated functional prototypes to test and optimize your design, select the right process, reduce costs, and shorten project cycles. On-demand services can produce automated parts with a high level of accuracy.

Automotive

Our sheet metal stamping services enables the production of a wide range of components that contribute to the performance, safety, and aesthetics of vehicles in the automotive industry.

Aerospace

Our stamping services provides high-quality, precise, and durable components that meet the demanding requirements of aircraft safety, performance, and reliability.

Medical Devices

Our sheet metal stamping services have been meticulously designed to meet the stringent requirements of the medical industry, ensuring that every component we produce meets or exceeds the highest standards.

Robotics

Our cutting-edge capabilities, innovative craftsmanship, and skilled engineering team could better serve the robotics field with advanced sheet metal stamping solutions.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Sheet Metal Stamping FAQs

Sheet metal stamping offers several advantages, including high production efficiency, consistent part quality, cost-effectiveness for high-volume production, the ability to create complex shapes and features, and compatibility with a wide range of materials. It also allows for automation, which can further enhance productivity.

Sheet metal stamping is used to manufacture a wide range of products across various industries. Common examples include automotive components (such as brackets, panels, and chassis parts), electrical and electronic components, appliances, aerospace parts, hardware, and various metal enclosures.

The metal stamping process typically involves the following steps: design and engineering, material selection, tool and die design, material blanking (cutting), forming (bending, drawing, etc.), secondary operations (such as piercing, threading, or welding), inspection, and finishing.

When designing parts for metal stamping, considerations such as material selection, part geometry, tolerances, draft angles, and bend radiuses are important. Design for manufacturability (DFM) principles should be applied to ensure efficient production and minimize potential issues.

Flat metal sheets are formed via a manufacturing technique called sheet metal stamping or pressing. A flat sheet of metal—either a blank or a coil—is placed in a sheet metal stamping press during this procedure, where a tool and die surface shape the metal into its desired form.

Sheet Metal, 24-gauge to 20-gauge Brass, copper, and sterling silver are all available in 24-gauge to 20-gauge sheets, which is ideal for sheet metal stamping.

You are usually only able to use relatively low-strength materials, including low-carbon iron or steel, due to the nature of sheet metal stamping processes. The tools frequently break when used with strong materials. By adding ribs and other radii, sheet metal stamped pieces can be made stiffer, but the material must still have some ductility.