Reaction Injection Molding Services

Our Custom Reaction Injection Molding Services

Providing perfect reaction injection molding solutions for complex geometries parts at competitive prices, with extensive experience in reaction injection molding, get a quote in minutes and get unmatched high-precision reaction injection molded parts in days!

- Advanced Equipment & Cost-Effective Price

- 20,000+Customers Served

- Tolerances Down to ±0.005mm

- ISO 9001 & ISO13485 Certified Factory

- 10+ Years of Reaction Injection Molded Parts

- 24/7 Engineering Support

STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T | IPT | CATPART | PDF

Max. file size: ≤20MB

- All uploads are secure and confidential.

Our Reaction Injection Molding Processes

Reaction injection molding is a preferred solution for the efficient and economical production of high-performance components, capable of producing lightweight, durable, and complex parts with excellent mechanical properties. As one of the top domestic RIM manufacturers, NOBLE allows you to obtain lightweight and complex parts at competitive prices in a short time from prototype design to production.

In standard RIM, two liquid components are mixed under high pressure and injected into a closed mold. A chemical reaction occurs inside the mold, causing the material to expand and solidify. It is widely used in producing automotive bumpers, medical equipment, and industrial equipment housings for its good stability and impact resistance.

- 10+ years of Reaction Injection Molding

- Competitive Price 30% Cost Save

- No Minimum Order Quantity

- Various Color and Texture Options

The reinforcement material is placed into the mold before injecting the reaction mixture. The polymer fills the mold and bonds with the reinforcement material to form a high-strength composite structure. It is widely used in the production of automotive structural components and aerospace parts due to its strong wear resistance and high strength.

- 1-to-1 Quote Analysis

- Competitive Price 30% Cost Save

- Functional Testing and Prototyping

- Free Dimensional Inspection Reports

RRIM adds reinforcing fillers to liquid resin. This process is similar to standard RIM but produces more durable and stable products. With its high impact resistance and strong chemical resistance, it is widely used in the production of automotive bumpers, industrial machinery parts, and medical equipment housings.

- Advanced Equipment & Cost-Effective Price

- 10+ years of Reaction Injection Molding

- ISO 9001 & ISO13485 Certified Factory

- 24/7 Engineering Support

Is a variation of RIM in which a chemical reaction produces a foam core with a solid shell, reducing weight and ensuring structural integrity. With its strong thermal and acoustic insulation properties, it is widely used in automotive dashboards, aerospace lightweight structural panels, and insulating shells of medical devices.

- Advanced Equipment & Cost-Effective Price

- 10+ years of Reaction Injection Molding

- Instant Reaction Injection Molding Quotes

- 24/7 Engineering Support

Involves the simultaneous injection of multiple reactive components to create a multi-layer structure. Different material properties can be combined in one part. The outer layer can be made rigid while the inner layer remains soft or foamed. It is widely used in automotive interior parts and industrial seals for its strong impact resistance and shock absorption.

- Advanced Equipment & Cost-Effective Price

- 10+ years of Reaction Injection Molding

- 1-to-1 Quote Analysis

- 24/7 Engineering Support

Use elastomer materials to produce flexible rubber-like parts. The liquid component solidifies to form a highly elastic and resilient material. It is widely used to produce soft automotive interiors and protective equipment due to its excellent impact absorption and flexibility.

- 10+ years of Reaction Injection Molding

- ISO 9001 & ISO13485 Certified Factory

- 1-to-1 Quote Analysis

- 24/7 Engineering Support

Our Reaction Injection Molding Capabilities

From Prototyping to Manufacturing

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and perfect quality inspection process to turn your ideas into reality.

Mold Design & Engineering

Injection mold design is a key element of the injection molding process as it plays an important role in determining the quality and precision of the final injection molded parts. NOBLE has a professional design team to provide you with the best injection mold design solutions.

- 10+ years of Mold Design & Engineering

- State-of-the-Art Equipment

- 1-to-1 Quote Analysis

- Free DFM Feedback

- Strong R & D capability

- Free DFM and Mold Flow Analysis Report

Mold & Prototype Manufacturing

Once the mold design is approved, we begin manufacturing the mold. We then perform prototype injection molding to quickly and efficiently produce and test them for small batch production of plastic parts.

- 10+ Years of Mold & Prototype Manufacturing

- Thousands of resins to choose from

- Competitive & Affordable Price

- State-of-the-art Equipment

- 100% Part Inspection

- Fast Lead Time

Low-Volume & Medium Injection

NOBLE meets your small and medium batch injection molding needs through strict tolerance control, quality inspection, and complete supply chain, and quickly delivers cost-effective, high-precision parts.

- 10+ Years of Medium & Low Injection Molding

- Competitive & Affordable Price

- State-of-the-art Equipment

- Guaranteed Consistent Quality

- 100% Part Inspection

- Fast Turn-Around Production

Why Choose Us for Custom Reaction Injection Molding Services

Choosing our custom reaction injection molding service brings numerous advantages that will make your product an industry leader. NOBLE utilizes advanced manufacturing equipment and superior reaction injection molding technology. Our experts are committed to reducing cycle time by up to 40%, ensuring you get a quote in minutes and get unparalleled high-precision reaction injection molded parts in a few days!

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

Advantages of Reaction Injection Molding

Reaction injection molding delivers a variety of advantages, making it a top choice for efficient and affordable production of intricate, lightweight, and premium-quality parts. Here are a few of the key benefits.

Our Reaction Injection Molding Procedure

At NOBLE, we’re proud to be one of China’s leading manufacturers in injection molding. We specialize in crafting high-quality plastic parts for large-scale production. The process is straightforward: molten plastic is injected into a mold, cooled and solidified, then ejected to create parts that perfectly fit your needs. Here’s how we ensure precision with every order:

Request Instant Quote

From the moment we receive your inquiry email, our professional engineers will provide a response within 24 hours to ensure a smooth process.

Engineer Evaluation

To ensure we can produce functional molds, we conduct a feasibility review of your design to ensure we can meet the requirements before commencing production.

Mold Flow Analysis

Predictive modeling software helps us understand how the molten material moves and acts within the mold, which helps us make improvements.

Mold Tooling Production

Using your preferred materials enables us to make mold tooling that is of high quality and can readily fit your applications.

Sample Inspection

Sampling will be delivered for you to review prior to manufacturing plastic parts to ensure precision and quality.

Low Volume Production

After the trial production phase, we begin batch production, which uses powerful machining to manufacture parts at fast rates to save on time and costs.

Strict Inspection

We follow international tolerance standards to ensure our parts meet your parameters.

Delivery

As our team handles packaging to secure our parts neatly for transport, we partner with logistics companies to schedule a timely delivery to your region.

Reaction Injection Molding Tolerances and Standards

There are many reaction injection molding manufacturers in China, and NOBLE has many years of experience in reaction injection molding. It can provide the most efficient and economical solution with unparalleled reaction injection molding precision to meet your unique needs, allowing you to get impeccable high-quality reaction injection molded parts or prototypes in advance. We can also achieve special tolerances if you indicate the requirements in the drawing.

| Standards | Description |

| Maximum Part Size | 78.7in*47.2in*39.37in (2000mm*1200mm*1000mm) |

| Minimum Part Size | 0.039in*0.039in*0.039in (500mm*500mm*500 mm) |

| Part to Part Repeatability | ±0.0039 in (±0.1 mm) |

| Thickness | Optimum casting thickness: 0.16in~0.31in(4~8mm), Maximum casting thickness: 0.79in(20mm) |

| Available Mold Types | ABS simple mold (50-100pcs); Resin simple mold (100-500pcs); Aluminum alloy mold (500-1000pcs) |

| Secondary Operations | Mold texturing, pad printing, laser engraving, threaded inserts and basic assembly. |

| Inspection and Certification Options | 15 business days or less for most orders, 24/7 quotation response |

Materials for Reaction Injection Molding

Materials used in Reaction Injection Molding are typically reactive liquids that undergo a chemical reaction within the mold to form solid parts. Below are the main types of materials used in reaction injection molding:

Polyurethane

Among the materials used in the reaction injection molding process, polyurethane stands out as the most commonly utilized. It strikes an excellent balance between strength, flexibility, durability, and lightness.

Epoxy Resins

While epoxy resins are less commonly used than polyurethanes in reaction injection molding, they remain a viable choice due to their outstanding chemical resistance and robust mechanical properties.

Phenolic Resins

If one were to select a resin for reaction injection molding where heat resistance and flame retardancy are critical, phenolic resins would be a strong candidate, particularly in structural applications where strength and high-temperature performance are crucial.

Polyurea

When quick production cycles are necessary, consider polyurea in the reaction injection molding process. Its rapid curing time, combined with excellent chemical and abrasion resistance, makes it ideal for parts exposed to heavy wear.

Wall Thickness: 0. 75 mm

Lead Time: 3 days

Tolerances: ±0. 01mm

Max part size: 200 x 80 x 100 cm

Surface Finishes for Reaction Injection Molding

The finish of a Reaction Injection Molded part plays a key role in its appearance, texture, durability, and compatibility with the application environment. Below are some of the most common surface finishes and the methods used to achieve them:

Glossy

A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts.

Semi-glossy

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture.

Matte

C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture.

Textured

D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish.

Quality Inspections for Our Reaction Injection Molding Service

NOBLE’s experienced engineers have the expertise and experience to meet your specific needs, can undertake complex and challenging injection molding projects, and strictly implement our demanding quality inspection process to ensure that you get low-cost and high-precision injection molded parts.

- Material Certificate

- Free DFM Design Feedback

- Weekly Mold Progress Report

- Trial Mold Parameter & Video Supplying

- T1 samples Inspection Report

- Inspection Report Before Shipment

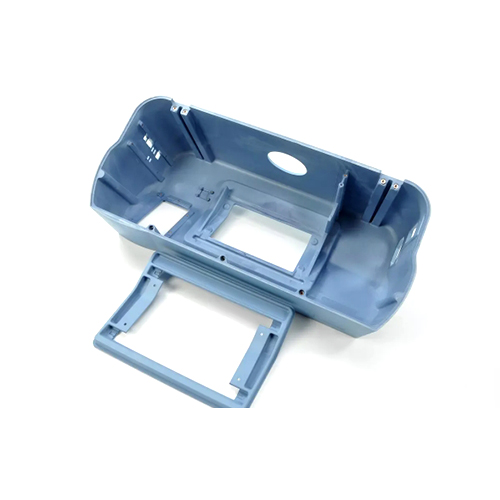

Custom Reaction Injection Molding Parts Display

From prototyping to reaction injection molding, at every step, we offer competitive pricing while demonstrating high quality, stable performance reaction injection molded parts to our valued customers.

See What Our Customers Say About Us

Customer feedback is one of the most valuable resources for any business. At NOBLE, we take pride in the positive relationships we build with our clients and value the trust they place in us. Here’s a glimpse of what some of our customers have shared about our reaction injection molding services:

Ethan Foster

Medical Equipment Supplier

NOBLE helped us create intricate medical components with precision. Their team ensured our complex designs were manufacturable while meeting safety and quality standards. They’ve been instrumental in our success with reliable, high-quality reaction injection molding parts for medical applications.

Leah Ross

Automotive Aftermarket Supplier

NOBLE’s expertise in complex reaction injection molding exceeded our expectations. They helped improve part performance with innovative solutions. Their attention to detail and professionalism make them a trusted partner for quality manufacturing and reliable, on-time delivery.

Mason Harris

Medical Equipment Supplier

NOBLE helped us create intricate medical components with precision. Their team ensured our complex designs were manufacturable while meeting safety and quality standards. They’ve been instrumental in our success with reliable, high-quality parts for medical applications.

Amelia Collins

Consumer Electronics Manufacturer

NOBLE offers rapid prototyping and quick turnarounds without compromising quality. Their team consistently delivers high-quality reaction injection molding parts on time, which is critical for our production schedule. A dependable partner for large-scale injection molding needs. Highly recommend.

Isabella Carter

Automotive Parts Supplier

We rely on NOBLE for high-volume automotive parts. Their precision and commitment to quality are unmatched. The customer service is responsive, ensuring that our strict standards are always met on time. Highly recommend for consistent results.

Reaction Injection Molding Service for Various Industries

Reaction Injection Molding delivers adaptable solutions for a wide range of industries, offering precision and efficiency in the production of various components. Here are a few more examples of how it’s used across different sectors:

Medical Devices

Reaction Injection Molding is perfect for complex medical components, offering precision, biocompatible materials, customizable designs, and sterilizable surfaces. It ensures high-quality, safe, and ergonomic parts meeting strict regulatory standards.

Automotive

Reaction Injection Molding provides durable, lightweight automotive parts with complex shapes, custom finishes, and integrated functions. It supports weight reduction, high-quality production, and low-to-medium volume runs, making it ideal for automotive components.

Robotics

Reaction Injection Molding is used to produce lightweight, precise robotic housings and components, as well as custom grip and interface parts designed for optimized dexterity and performance in industrial robots.

Energy

Reaction Injection Molding is used for creating durable components in renewable energy, such as wind turbine blades, nacelle covers, and battery housing, ensuring strength, safety, and resistance to extreme weather conditions.

Industrial Equipment

Reaction Injection Molding produces strong protective casings for industrial machinery and custom seals and gaskets, ensuring leak resistance, thermal insulation, and durability under harsh operating conditions.

Consumer Products

Reaction Injection Molding is ideal for creating sturdy enclosures for electronics like smartphones, laptops, and wearables, along with complex keypads and switches that require tactile feedback and durability.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!

Reaction Injection Molding FAQs

Reaction Injection Molding is a manufacturing process where two reactive materials, usually polyurethanes or other thermoset resins, are mixed and injected into a mold. These materials chemically react inside the mold, curing into a solid part.

Unlike traditional Injection Molding, which uses thermoplastic materials, Reaction Injection Molding involves thermoset resins that react and cure inside the mold, offering enhanced durability, chemical resistance, and flexibility in material properties.

Polyurethane offers excellent flexibility, durability, abrasion resistance, and chemical resistance. It can be tailored to produce both soft and hard parts, making it ideal for applications ranging from automotive bumpers to medical device housings.

Cycle times in Reaction Injection Molding typically range from 30 seconds to several minutes, depending on part size, material, and mold design. The cycle includes time for mixing, injection, curing, and cooling.

- Material limitations: Not all materials are suitable for the process.

- Complexity in mold design: Requires careful design to accommodate chemical reactions and curing times.

- High initial tooling costs for creating molds, although it becomes more cost-effective at scale.

Yes, Reaction Injection Molding is well-suited for producing large parts. The process can accommodate large mold cavities and is effective in creating parts that are both lightweight and strong, such as automotive bumpers or aerospace components.

- Clear Design Specifications

Clear design specifications ensure that the mold and materials used in Reaction Injection Molding match the final product’s requirements for shape, strength, and functionality.

- Iterative Testing and Refinement

Iterative testing and refinement in Reaction Injection Molding allow adjustments in materials and mold designs to ensure the final product meets performance and aesthetic standards.

- Material Selection Consistency

Consistent material selection in Reaction Injection Molding is vital to ensure that the prototype and final production parts share the same strength, flexibility, and durability properties.

- Close Collaboration Between Design and Manufacturing Teams

Close collaboration ensures that mold design, material selection, and process optimization in Reaction Injection Molding result in high-quality, efficient production.

- Quality Control During Prototyping

Rigorous quality control during prototyping in Reaction Injection Molding ensures that dimensional accuracy, material curing, and part functionality are validated before scaling to full production.

- Advanced Manufacturing Techniques

Reaction Injection Molding is an advanced manufacturing technique that allows precise control over material flow and curing, ensuring high-quality parts in mass production.

- Design for Manufacturability

Designing prototypes for manufacturability in Reaction Injection Molding ensures that the final design is suitable for efficient production without compromising quality or increasing costs.

- Feedback Loops and Continuous Improvement

Feedback from Reaction Injection Molding prototype testing helps optimize material properties, mold designs, and production processes, reducing defects and improving final product quality.