POM Injection Molding Service

Custom POM Injection Molding Service

Custom parts manufacturing, from rapid prototyping to on-demand production. Instant quotes and DFM analysis in seconds, quality parts in days.

- 100% POM Part Inspection

- Quote Within 24 Hours

- High Quality and Consistency

- Competitive Price 30% Cost save

- Fast Turn-around Production

- Satisfied Clients 100%

Our POM Injection Molding Capabilities

NOBLE delivers high-quality precision injection molding with an incredible range of manufacturing capabilities. From prototyping to mass production of POM parts, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

| Price | $$$ |

| Lead Time | < 7 days |

| Wall Thickness | 0.045 in. – 0.140 in. (1.143mm – 3.556mm) |

| Tolerances | +/- 0.003 in. (0.08mm) with an included resin tolerance that can be greater than but no less than +/- 0.002 in./in. (0.002mm/mm) |

| Max Part Size | 18.9 in. x 29.6 in. x 8 in. (480mm x 751mm x 203mm) |

| Available POM at NOBLE | Delrin 100P, Delrin 100AF, DuPont Delrin 500AF, POM-H+PTFE(Delrin 500P) |

Characteristics of POM Injection Molding Materials

Polyoxymethylene (POM), commonly known as acetal or Delrin, is a highly versatile thermoplastic material often chosen for injection molding due to its excellent mechanical and thermal properties.

| Features | Info |

| Subtypes | POM Copolymer, POM Homopolymer, POM-H+PTFE |

| Process | CNC Milling, CNC turning, laser cutting, injection molding, drilling and tapping |

| Tolerance | +/- 0.003 in. (0.08mm) with an included resin tolerance that can be greater than but no less than +/- 0.002 in./in. (0.002mm/mm) |

| Applications | Automotive Parts, Industrial Equipment, Medical Devices, Electronics and Electrical Components, Aerospace Parts, Robotics Parts |

| Finishing Options | Polishing, Sand Blasting, Laser Carving, Painting, Chroming (for Modified POM Grades), Tumbling, Flame Polishing |

Pros and Cons of POM for Injection Molding

POM is a popular thermoplastic material used in injection molding due to its excellent mechanical properties. In order to fully utilize its performance, it is essential to understand the advantages and disadvantages of POM. Here’s an overview of the pros and cons of using POM for injection molding:

High Strength and Rigidity

POM offers excellent tensile strength and stiffness, making it suitable for durable, load-bearing parts like gears and structural components that require high strength and resistance to deformation in injection molding.

Low Friction and Self-Lubricating

With a low coefficient of friction, POM reduces wear on moving parts, providing natural lubrication and making it ideal for injection-molded applications like gears and bearings that benefit from reduced friction.

Excellent Dimensional Stability

POM maintains precise dimensions due to minimal shrinkage and warping during injection molding, ensuring high accuracy, even for tight tolerances and complex parts.

Good Chemical Resistance

POM resists a wide range of chemicals, including oils and solvents, making it ideal for injection-molded components exposed to harsh chemical environments.

Good Wear and Abrasion Resistance

POM’s durability against wear and abrasion makes it suitable for moving parts, like gears and bushings, that experience continuous friction without degrading, especially in injection-molded components.

Ease of Injection Molding

POM is easy to mold, offering a smooth finish and tight tolerances with minimal mold wear, which reduces production costs in high-precision, high-volume injection molding.

Lightweight

POM is lightweight compared to metals, making it an excellent choice for applications where strength is required without adding significant weight, especially in injection-molded parts.

Low UV Resistance

POM degrades under prolonged UV exposure, which can cause brittleness and limit its use outdoors or in environments with high UV radiation unless treated with UV stabilizers during the molding process.

Temperature Sensitivity

POM softens at higher temperatures, limiting its use in applications exposed to extreme heat. It’s best suited for injection-molded parts intended for environments below 212℉.

Moisture Absorption

POM absorbs moisture from the air, which can cause dimensional changes and instability in injection-molded parts unless carefully dried and controlled during processing and storage.

Brittleness at Low Temperatures

POM becomes brittle in cold temperatures, making it less suitable for applications in freezing or sub-zero environments where flexibility is needed, particularly in injection-molded components.

Cost

POM tends to be more expensive than other plastics, which may make it less viable for budget-conscious, high-volume injection molding applications compared to cheaper alternatives like ABS and PVC.

Limited Electrical Insulation

POM provides some insulation but is less effective than materials like PTFE or composites for electrical applications requiring superior electrical resistance.

Types of POM Injection Molding Materials

POM materials have broad application prospects and significant value in injection molding. With advanced equipment and years of experience, our specialists consistently deliver POM products that surpass client expectations, reflecting our mastery in manufacturing intricacies.

Delrin 100P

Delrin 100P is a general-purpose POM material known for its excellent mechanical properties, including high tensile strength, stiffness, and dimensional stability. It is easy to injection mold and provides good wear resistance, making it ideal for precision parts, gears, bearings, automotive components, and machinery applications.

Tensile Modulus: 2,800 MPa

Tensile Strain (Yield): 20 – 30%

Rockwell Hardness: M-Scale: 90; R-Scale: 115

Heat Deflection Temperature: Unannealed: 190°F; Annealed: 210°F

Delrin 100AF

Delrin 100AF is a modified version of Delrin 100P, enhanced with PTFE (Polytetrafluoroethylene) for improved low friction and wear resistance. This modification makes it perfect for injection molding applications that require reduced friction, such as bearings, bushings, and sliding parts, where long-term durability and smooth performance are critical.

Tensile Modulus: 2,800 – 3,000 MPa

Tensile Strain (Yield): 20 – 25%

Rockwell Hardness: M-Scale: 90 ; R-Scale: 115

Heat Deflection Temperature: Unannealed: 185°F; Annealed: 205°F

DuPont Delrin 500AF

DuPont Delrin 500AF is another PTFE-modified POM, offering superior frictional properties and wear resistance. It is designed for high-performance, high-load, and high-speed injection molding applications. Commonly used in gears, bushings, and industrial machinery components, Delrin 500AF excels in environments demanding both strength and low friction for enhanced durability and efficiency.

Tensile Modulus: 2,600 – 3,000 MPa

Tensile Strain (Yield): 20 – 25%

Rockwell Hardness: M-Scale: 90-92; R-Scale:115-118

Heat Deflection Temperature: Unannealed: 185°F; Annealed: 205°F

POM-H+PTFE(Delrin 500P)

This is a PTFE-enhanced grade of POM designed to provide excellent wear resistance and reduced friction. It is commonly used in precision components such as bearings, seals, and moving parts. The addition of PTFE to the injection molding process improves its performance in dynamic and high-load environments, ensuring longer service life and reliable operation.

Tensile Modulus: 2,700 – 2,900 MPa

Tensile Strain (Yield): 20 – 25%

Rockwell Hardness: M-Scale: 90; R-Scale: 115

Heat Deflection Temperature: Unannealed: 190°F; Annealed: 210°F

Surface Finishing Options for POM Injection Molding

The right finishing technique can improve wear resistance, reduce friction, and provide a smoother surface for assembly. Step up the quality of your projects today!

Polishing

Working on metal and hard plastics, our polishing uses highly efficient machinery to get our parts between Ra 0.8~Ra0.1 for a cleaner surface.

Sand Blasting

Band blasting cleans the surface of any impurities and peels coating through the propelling of blast media streams over the parts.

Laser Carving

Helpful in brand recognition or parts organization, we use laser carving that applies various printing methods during full-scale production to quickly embed barcodes, lettering and logos on the parts.

Painting

Painting involves Spray droplets can be dispersed uniformly or in fine amounts to cover a wide surface area and bring out greater color to the part.

Chroming (for Modified POM Grades)

Chroming involves electroplating a layer of chrome onto POM components, typically modified with additives. It enhances wear resistance, hardness, and aesthetic appeal while improving the part’s corrosion resistance in demanding environments.

Tumbling

Tumbling titanium smooths its surface, often resulting in a matte finish. It’s used for deburring or preparing titanium parts for further finishing or aesthetic enhancement.

Flame Polishing

Flame polishing uses a controlled flame to slightly melt the surface of POM, smoothing out imperfections and creating a high-gloss finish. It’s commonly used for clear, transparent POM parts where aesthetics are crucial.

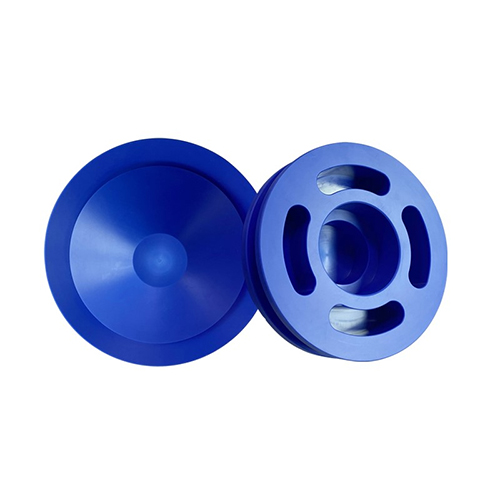

Custom POM Injection Molding Parts Display

Check out our over a decade of custom POM injection molding, including precision POM prototypes and parts from our valued customers.

Applications of POM Injection Molding

Our high-precision POM components are ideal for industries such as aerospace, automotive, medical, industrial, consumer electronics, and more. We provide Certificates of Conformance (CoCs), material certifications, finishing certifications, inspection reports, and hardware certifications.

Automotive Parts

Injection-molded POM is ideal for automotive components like gears, bushings, and fuel system parts. Its low friction and durability make it perfect for high-performance applications, enhancing the longevity and reliability of engine and transmission components.

Industrial Equipment

POM produces precision parts like pulleys, rollers, and bearings. Its wear resistance and low friction make it an excellent choice for industrial machinery, ensuring components perform reliably under high stress and continuous motion.

Medical Devices

POM is essential for medical components like surgical instruments and pumps. Through injection molding, the material's biocompatibility, precision, and resistance to sterilization processes ensure it is reliable and safe for use in healthcare applications.

Electronics and Electrical Components

POM is injection-molded into precise electrical connectors, insulators, and cable management parts. Its insulating properties and mechanical strength make it ideal for high-reliability electronic components that require durability and resistance to abrasion.

Aerospace Parts

Injection-molded POM is used in aerospace for lightweight, durable parts like bushings, seals, and actuators. Its strength, dimensional stability, and resistance to temperature variations make it suitable for demanding aerospace applications.

Robotics Parts

POM is used in the production of robotic joints, gears, and end-effectors, and is characterized by low friction and high durability. Its precision and strength help minimize wear, making it an ideal material for robotic systems requiring reliability in repetitive tasks.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!