Steel Sheet Metal Fabrication Service

Custom Steel Sheet Metal Fabrication Service

Use advanced sheet metal fabricated technology to customize high-strength, precision, and surface-finished parts. Produced by a professional team can operate stably in the most harsh environments.

- High Quality and Consistency

- 10+ Years of Sheet Metal Fabrication

- 24H instant price & DFM

- Cost-effective and Quality Assured

- 100% Satisfaction Guarantee

- Excellent Supplier from China

Our Steel Sheet Metal Fabrication Capabilities

Steel is a crucial iron-carbon alloy with a carbon content ranging from 0.02% to 2.11%. It combines the high strength of iron with the hardness and wear resistance of carbon, while possessing excellent ductility and malleability. In terms of performance, steel exhibits high tensile strength, high yield point, good impact toughness, and superior fatigue strength, making it the preferred material in the construction and other sectors. Additionally, steel is widely utilized in infrastructure fields such as railways, petroleum, chemicals, and electricity. Furthermore, steel’s recyclability embodies its environmentally friendly and sustainable characteristics.

| Price | $$$ |

| Lead Time | < 10 days |

| Wall Thickness | 0.75 mm |

| Tolerances | ±0.005″ (±0.125mm) |

| Max Part Size | 200 cm x 80 cm x 100 cm |

| Available Steel at NOBLE | Carbon Steel: 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, ST37 Alloy Steel: 4J36 Die Steel: 718H, P20, S136, S7 Chisel Tool Steel: D2/SKD11, SKD61 High Speed Steel: SKH51 Spring Steel: 1566, 9260 Tool Steel: A2 Bearing Steel: E51100/SUJ1, E52100/SUJ2 Galvanized Steel: SGCC / SECC SPCC |

Characteristics of Steel Sheet Metal Fabrication Materials

Steel parts sheet metal fabrication and manufacturing is one of our main type, below is some common information about Steel.

| Features | Info |

| Subtypes | Q195,Q215,Q235,Q255,Q275,08 and 08F Steel,10 an,10F Steel,20 Steel,45 Steel,40Cr Steel,35CrMo Steel,42CrMo Steel |

| Process | Sheet metal fabrication, sheet metal fabrication,die casting |

| Tolerance | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

| Applications | Fixtures and mounting plates; draft shafts, axles, torsion bars |

| Finishing Options | Black Oxide, ENP, Electropolishing, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing, Zinc Plating |

Pros and Cons of Steel for Sheet Metal Fabrication

Versatile Applications

As a versatile material, steel holds immense potential for application in the field of sheet metal fabrication. It can be utilized to manufacture a diverse range of mechanical parts, tools, and equipment, catering to various industrial requirements.

Cost-Effectiveness

In comparison to some high-performance tool materials, steel boasts a relatively lower price point, rendering it a more cost-effective option in sheet metal fabrication. Furthermore, the durability and recyclability of steel contribute to further reductions in processing costs.

Excellent Machinability

Steel possesses exceptional machinability, allowing it to be readily cut or shaped during sheet metal fabrication to achieve the desired part structure. The precision capabilities of sheet metal fabrication further ensure that steel parts are produced to a high quality standard.

Corrosion and Wear Resistance

Steel parts typically demonstrate superior corrosion and wear resistance, which extends their lifespan and service duration. These properties make steel an ideal choice for applications requiring long-term exposure to wear and corrosion.

Versatile Applications

As a versatile material, steel holds immense potential for application in the field of sheet metal fabrication. It can be utilized to manufacture a diverse range of mechanical parts, tools, and equipment, catering to various industrial requirements.

Versatile Applications

As a versatile material, steel holds immense potential for application in the field of sheet metal fabrication. It can be utilized to manufacture a diverse range of mechanical parts, tools, and equipment, catering to various industrial requirements.

Sheet Metal Fabrication Cycle Time

Compared to lightweight materials (such as steel), steel possesses a greater density, necessitating longer periods to remove excess billet material during the machining process. This phenomenon can result in decreased machining efficiency, particularly in large-scale production environments where the impact is particularly pronounced.

Energy Consumption

Sheet metal fabrication of steel typically requires greater energy consumption. This is primarily due to steel’s high hardness and density, necessitating larger cutting forces and power to complete the machining process. This has the potential to increase machining costs.

Corrosion Susceptibility

Steel can be highly susceptible to corrosion when exposed to certain environments, unless it undergoes specific treatment processes or is alloyed with other elements to enhance its resistance to corrosion.

Tool Wear

The hardness and toughness characteristics of steel can cause significant wear on cutting tools, especially during extended or continuous machining processes. This wear can lead to shortened tool life, necessitating more frequent tool replacements.

Types of Steel Sheet Metal Fabrication Materials

NOBLE has more than ten years of experience in surface treatment and excellent engineers, who are proficient in surface treatment of plastics, metals, and composite materials, and can turn your dream prototype or parts into reality.

Q195

With low carbon content, it offers good plasticity, toughness, machinability, and weldability but moderate strength. Commonly used for rolling thin sheets and coils, as well as cold- and hot-rolled galvanized and tinplate composite sheets for roofing panels, decorative sheets, general-purpose dust removal piping, packaging containers, etc.

Yield Strength(MPa): 195MPa

Elongation at Break(%): ≥33% (for thicknesses ≤16mm) ≥32%(for thicknesses>16-40mm)

Hardness(Brinell): 130-240HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: -20~500℃ at usually (Varies with heat treatment)

Q215

Slightly stronger than Q195, it shares similar applications and is also extensively used for welded steel pipes, galvanized welded pipes, furnace supports, anchor bolts, bolts, round nails, wood screws, stamped iron hinges, and other hardware components.

Yield Strength(MPa): 215MPa (decreasing with increasing thickness)

Elongation at Break(%): ≥31% (for thicknesses ≤40mm)

Hardness(Brinell): 230HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: -40~200℃ at usually

Q235

Balances strength, plasticity, and weldability well. It is the most widely used grade. Applications include rolled steel shapes (such as round bars, square bars, flat bars, angle bars, I-beams, channel beams, window frame steel, etc.) and medium-thick steel plates for construction and engineering structures (like reinforcing steel bars, factory building frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.). It is also widely used for mechanical parts with moderate performance requirements.

Yield Strength(MPa): 235MPa

Elongation at Break(%): 26%

Hardness(Brinell): 170-210HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: 0~350℃ at usually

Q255

Similar properties to Q235 but with slightly higher strength and lower plasticity. Less commonly used than Q235, primarily for riveted and bolted structures.

Yield Strength(MPa): 255MPa

Elongation at Break(%): 24% (for thicknesses ≤16mm)

Hardness(Brinell): HB220~250

Density(G/m³): ≈7.85 G/m³

Maximum Temp: -20~50℃ at usually

Q275

Higher strength and hardness with good wear resistance. Used for manufacturing shafts, agricultural implements, wear-resistant parts, rail joint splints, base plates, wheels, rolls, etc.

Yield Strength(MPa): 275MPa

Elongation at Break(%): 17~22%

Hardness(Brinell): 270~400HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: 200~300℃ at usually

08 and 08F Steel

Used for rolling thin sheets, deep-drawn products, oil drums, high-quality enamelware, and also for pipes, gaskets, and parts requiring low core strength such as carbonized and cyanided parts, welding electrodes, etc.

Yield Strength(MPa): 175MPa

Elongation at Break(%): ≥35%

Hardness(Brinell): 131HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: ≥200℃ at usually

10 and 10F Steel

Suitable for cold deep-drawing products under 4mm thick, such as deep-drawn containers and artillery shells. Also used for boiler tubes, oil drum covers, steel strips, steel wires, welded parts, and mechanical parts.

Yield Strength(MPa): 185MPa

Elongation at Break(%): ≥30%

Hardness(Brinell): 137HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: ≥470℃ at usually

20 Steel

Good weldability and plasticity, suitable for cold pressing and cold rolling. Often used for manufacturing parts and components like bolts, nuts, bearings, and pins.

Yield Strength(MPa): 355MPa

Elongation at Break(%): ≥25%

Hardness(Brinell): 156HB

Density(G/m³): ≈7.85 G/m³

Maximum Temp: -20~425℃ at usually

Surface Finishing Options for Steel Sheet Metal Fabrication

NOBLE has more than ten years of experience in surface treatment and excellent engineers, who are proficient in surface treatment of plastics, metals, and composite materials, and can turn your dream prototype or parts into reality.

As Machined

Coming out of the machine after machining, our parts are cleaned of any sharp edges and burrs while retaining marks. Without any added material, the part had a surface roughness of 3.2 μm (126 μin).

Polishing

Working on metal and hard plastics, our polishing uses highly efficient machinery to get our parts between Ra 0.8~Ra0.1 for a cleaner surface.

Sand Blasting

Band blasting cleans the surface of any impurities and peels coating through the propelling of blast media streams over the parts.

Laser Carving

Helpful in brand recognition or parts organization, we use laser carving that applies various printing methods during full-scale production to quickly embed barcodes, lettering and logos on the parts.

Alodine

We use chromate conversion coating or alodine to protect titanium and other materials from corrosive elements, usually done before priming and painting parts.

Anodizing

To increase surface hardness and dissipate heat, we use anodizing techniques to enhance the look of parts and blend well for painting and priming.

Powder coating

We apply a thin layer of protective polymer with the corona discharge phenomenon to give our part a lasting finish that protects from impacts and prevents wearing down.

Brushing

Our brushing technique uses abrasive belts over the material to create diverse patterns that match the parts’ structure and color.

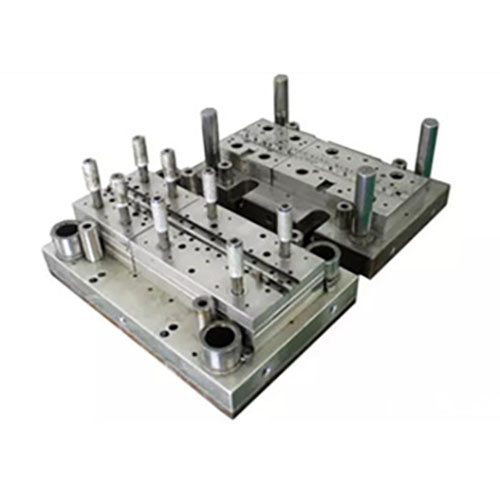

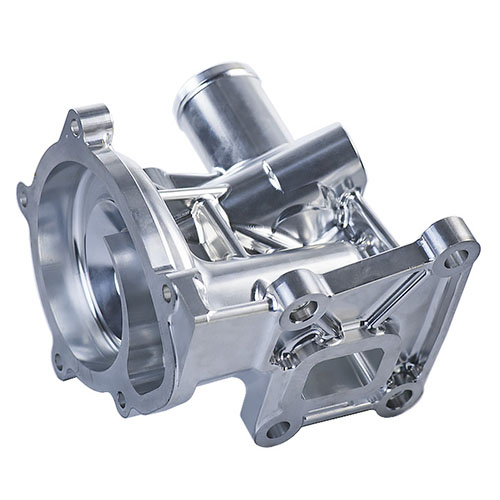

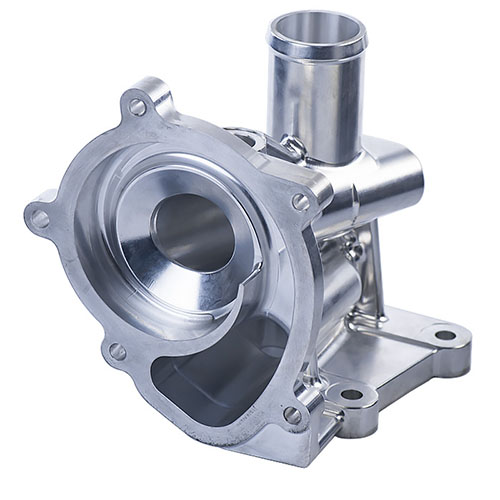

Custom Steel Sheet Metal Fabrication Display

Check out our over ten years of custom steel sheet metal parts, including precision steel prototypes and parts from our valued customers.

Applications of Steel Sheet Metal Fabrication

Steel sheet metal fabrication is widely utilized across various industries, including aerospace, automotive, electronics, medical devices, and robotics, for producing lightweight, high-precision components such as aircraft parts, enclosures, surgical instruments, and robotic components.

Automotive Parts

Steel sheet metal fabrication is heavily used in the automotive industry to produce lightweight, high-performance components. By utilizing steel, manufacturers can reduce the overall weight of vehicles, leading to improved fuel efficiency, better handling, and enhanced vehicle performance.

Aerospace Parts

In the aerospace sector, steel sheet metal fabrication is employed to manufacture lightweight and strong components, such as fittings, brackets, housings, and interior parts, which are critical for reducing the overall weight of aircraft. Steel's strength-to-weight ratio makes it perfect for aerospace applications where both durability and lightness are essential to ensure safe and efficient flight.

Medical Devices

Steel sheet metal fabrication plays a crucial role in the medical industry by producing lightweight, high-precision components like surgical instruments, diagnostic equipment housings, and implantable devices. Steel's biocompatibility, corrosion resistance, and ability to achieve tight tolerances make it an excellent choice for medical device manufacturers requiring high-quality, reliable components.

Robotics Parts

In the robotics industry, steel sheet metal fabrication is essential for producing precision components such as robotic frames, joints, gears, and connectors. Steel's lightweight and strong properties help create efficient and reliable robotic systems that can handle complex movements and dissipate heat effectively, enabling robots to perform specific functions with higher precision and longer operational lifespans.

Industrial Equipment

Steel sheet metal fabrication is widely used in the production of lightweight and durable components for industrial equipment. It allows for the creation of complex, high-precision parts that are vital to machinery performance and operational efficiency. Steel components contribute to equipment longevity and performance, offering flexibility in design and customization for various industrial applications.

New Energy

In the new energy sector, steel sheet metal fabrication supports the production of lightweight, precise components essential for the development of renewable energy technologies, such as solar panels, wind turbines, and battery housings.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!