Professional Custom Parts Machining Service Provider

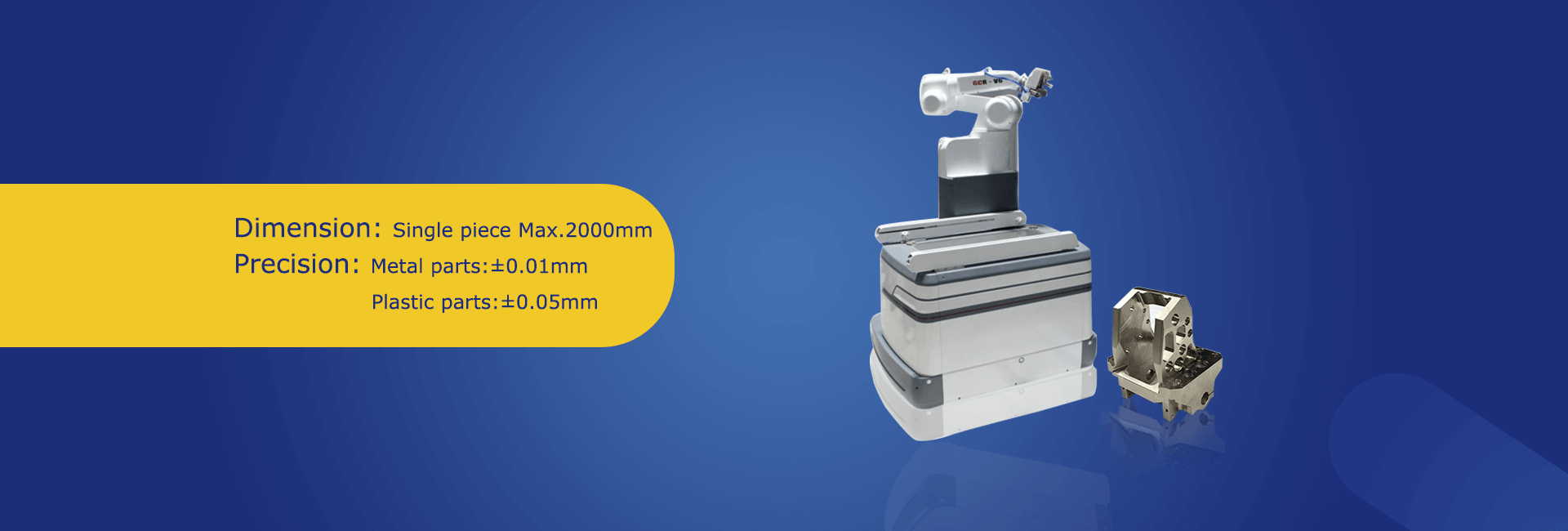

NOBLE is your trusted one-stop custom manufacturing solution. From prototyping to manufacturing, with competitive prices, you can get complex and high-quality parts in as fast as one day.

Our On-Demand Projects Supporting Services

NOBLE is a Sino-British joint venture awarded by the government as a “National High-tech Enterprise”. We have two major business directions: “Smart Manufacturing” and “Care Products”. The “Smart Manufacturing” business specializes in providing customers with projects supporting services including parts machining and manufacturing.

More than 10 years of professional manufacturing and rapid prototyping experience. Our efficient team provides strong support for your new projects to 100% realize your requirements; Standardized management brings strictly quality control of parts & products; Reasonable workflow gets lower cost with the same quality ……

What Makes Us Exceed the Counterparts

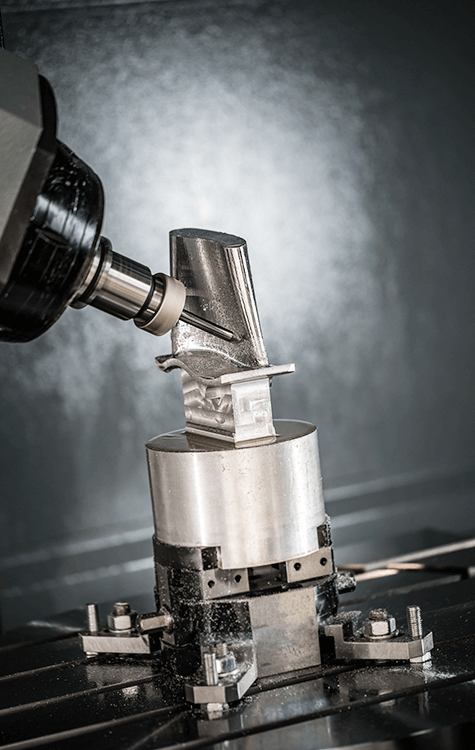

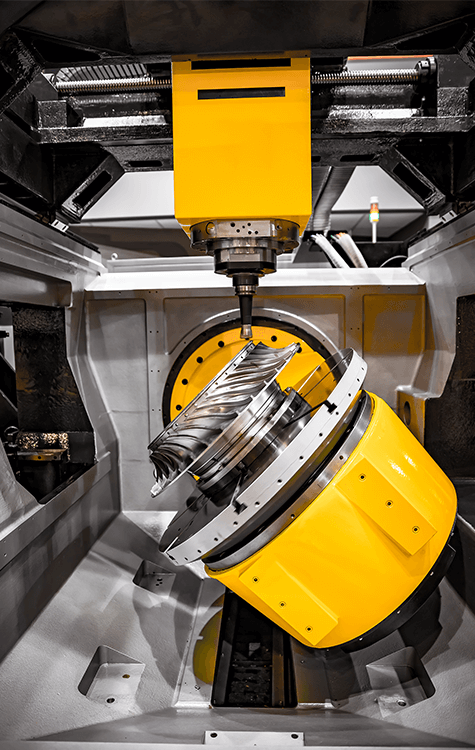

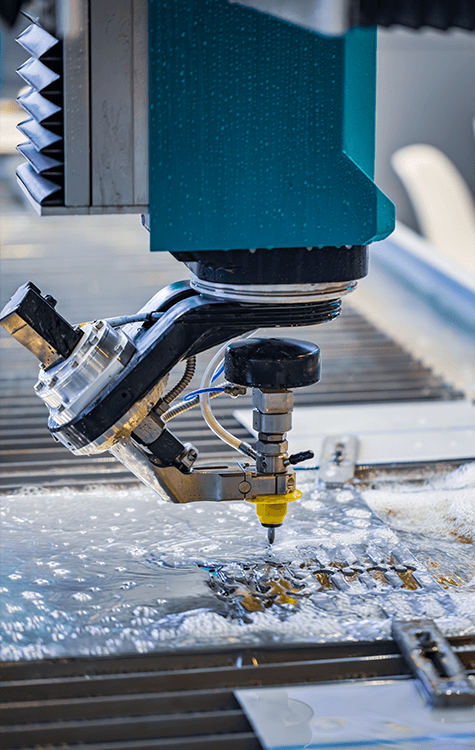

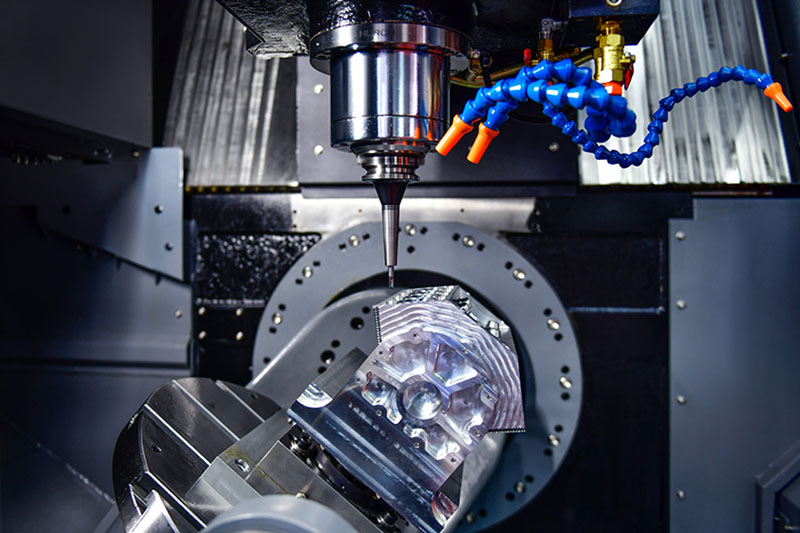

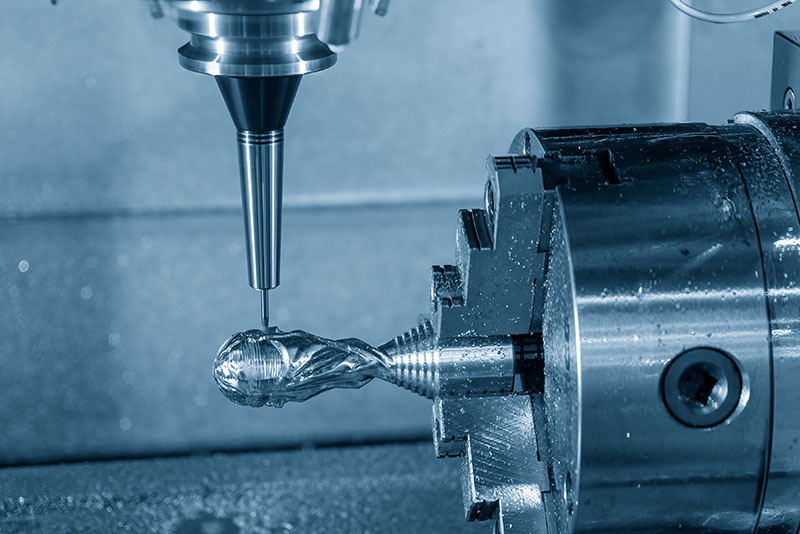

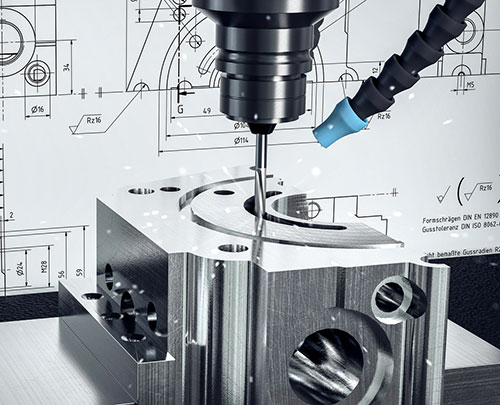

Turn your concept into reality through outstanding on-demand manufacturing services. NOBLE produces simple and complex prototypes and end-use parts with powerful and efficient manufacturing capabilities. All our products meet strict tolerance criteria and quality standards, making us the leading on-demand manufacturing company in China.

Work with Us in 4 Simple Steps Only

With many years of manufacturing experience, NOBLE offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

From Prototyping to Production

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, through huge manufacturing resources, suitable technology, streamlined process, expert guidance, and a perfect quality inspection process to turn your ideas into reality.

From NOBLE, you can get your prototypes done in days, which allows you to verify the design fast.

- 10+ Years of Rapid Prototyping

- State-of-the-art Equipment

- Competitive & Affordable Price

- Quote Within 24 hours

- Trusted & Reliable Factory

- Fast Turnaround in 7 days

Rapid tooling is a cost-efficient way to bridge the gap between prototyping and final production. Launch your products to the market fast.

- 10+ Years of Low-Volume Manufacturing

- 500+Production Equipments

- Competitive & Affordable Price

- 1000+Clients To Work With

- 100,0000+ Unique parts produced

- 100+ Countries shipped

On-Demand Production

For production projects, our engineering team will support you to achieve the best products in terms of quality and cost.

- 10+ Years of Medium&Mass Production

- Served 50,000+ Product Developers

- Competitive & Affordable Price

- Large Supplier Network

- 100% Part Inspection

- Fast Turn-Around Production

Our Clients

Six Reasons For Choosing NOBLE For Precision Parts Machining

Rapid Lead Time

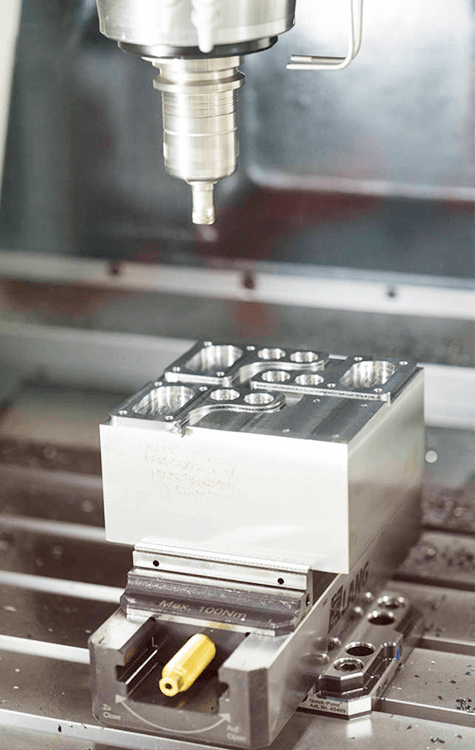

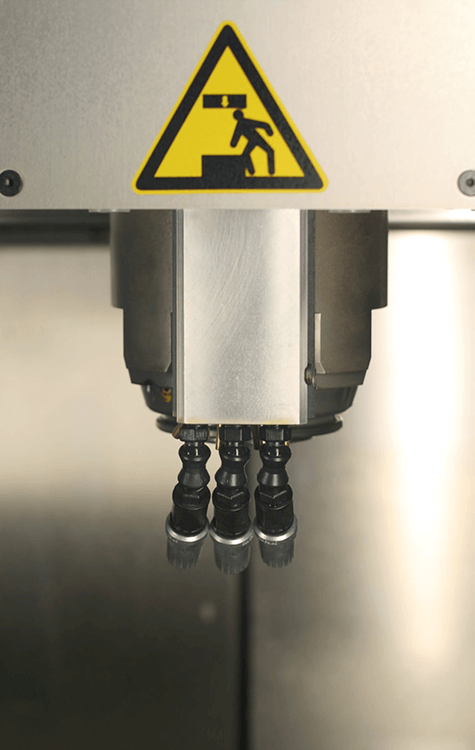

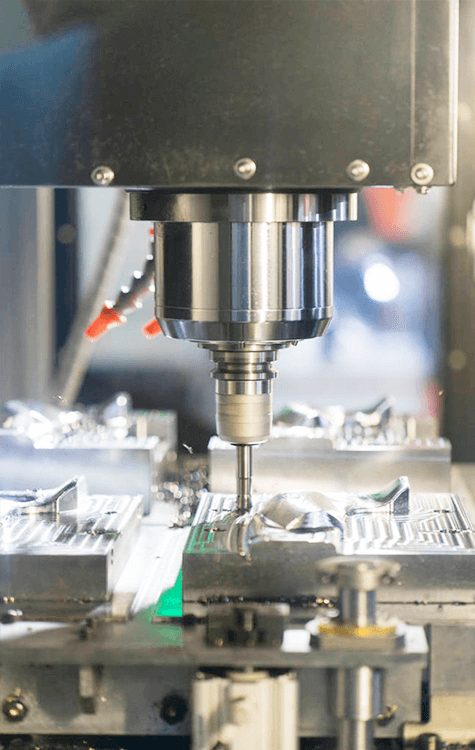

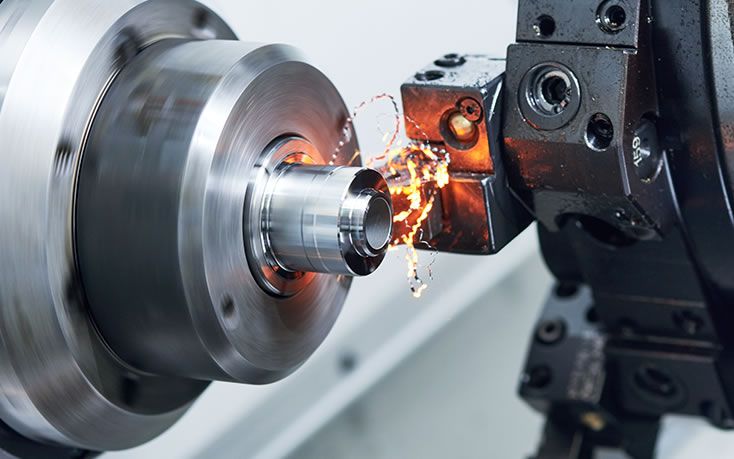

Your parts can be finished rapidly within 7-10 days with the support of comprehensive CNC software and experienced engineers.

Real-time Pricing

A quick and professional quote can be offered within 24 hours after you submit an RFQ with the information needed.

Incredible Capabilities

Extensive capabilities inhouse can meet your requirements from design, and prototypes to mass production of parts.

Sophisticated Testing Equipment

A full set of inspection equipment & overall quality control system ensure your prototypes or components are created with high accuracy.

Global Supply Network

We have worldwide distribution channels and an excellent transportation chain, allowing your parts to be delivered on time.

Industry-leading Expertise

Advanced rapid prototyping and rapid manufacturing technology to machine various metal and plastic materials as per specifications stated.

Our Customers' Reviews

We have been ordering CNC parts from NOBLE for over 5 years. Their quality and

services are way better than what we can get from the other Chinese CNC machine

shops. We always receive a fast quotation after we send through RFQs. Normally,

within 12 hours or shorter which helps a lot. The projects we receive from

NOBLE, both materials and geometry are always 100% matched every time. We are

more than happy to stick to their services in the long term.

Luc Szorc

We have been ordering CNC parts from NOBLE for 8 years. Their quality and service

are superior to many other suppliers. NOBLE has rich experience in professional

manufacturing and rapid prototyping. Provide prompt responses and timely

feedback with enthusiasm. It is one of our best and most reliable suppliers.

Mark

As a long-term partner of NOBLE, NOBLE has provided us with quality and efficient

service over the past decade. NOBLE has standardized management, strict control

of parts, and product quality, and 100% can meet our requirements.

Good workflow, with the same quality premise, provides a better price. Efficient

technical and service team focused on support and assistance throughout the

project.

Raymond

Machined Part Quality Ensured By Professional Experience

Our company has ISO 9001-2015 and ISO13485-2016 certificates, complete quality control and experimental equipment, and complete IQC, IPQC, and FQC/OQC inspection processes in production, and can provide perfect quality control according to customer requirements. Through sophisticated in-house test and measurement tools, we ensure that every component meets your intended specifications.

NOBLE has a dedicated and competent team of engineers and technicians who are available to help you with your issues through 24/7 proactive and professional support.

- 1-on-1 Technical Support

- Professional Design Support

- Elite Engineers & Technicians

We strictly follow the ISO9001 quality control system to ensure that the quality of parts processed in the production workshop meets your requirements.

- ISO 9001 & ISO13485 Certified Factory

- IQC, IPQC, FQC/OQC Inspection Process

- Advanced Machining & Testing Equipment

Rework and Privacy Policy

If you receive a part that does not meet the specifications, please contact us by email in time, we will solve your problem within 1-3 working days. For the machined parts, we will strictly abide by the confidentiality control procedures and have established a complete confidentiality process.

- Perfect After-sales Service

- Perfect Confidentiality Policy

- Responsive Reply & Support

Work with Numerous Industries

From prototyping to production, NOBLE ensures superior quality and reliable functionality. With an extensive selection of production-grade metal and plastic materials and highly advanced on-demand manufacturing techniques, we supply high-quality products to multiple industries.